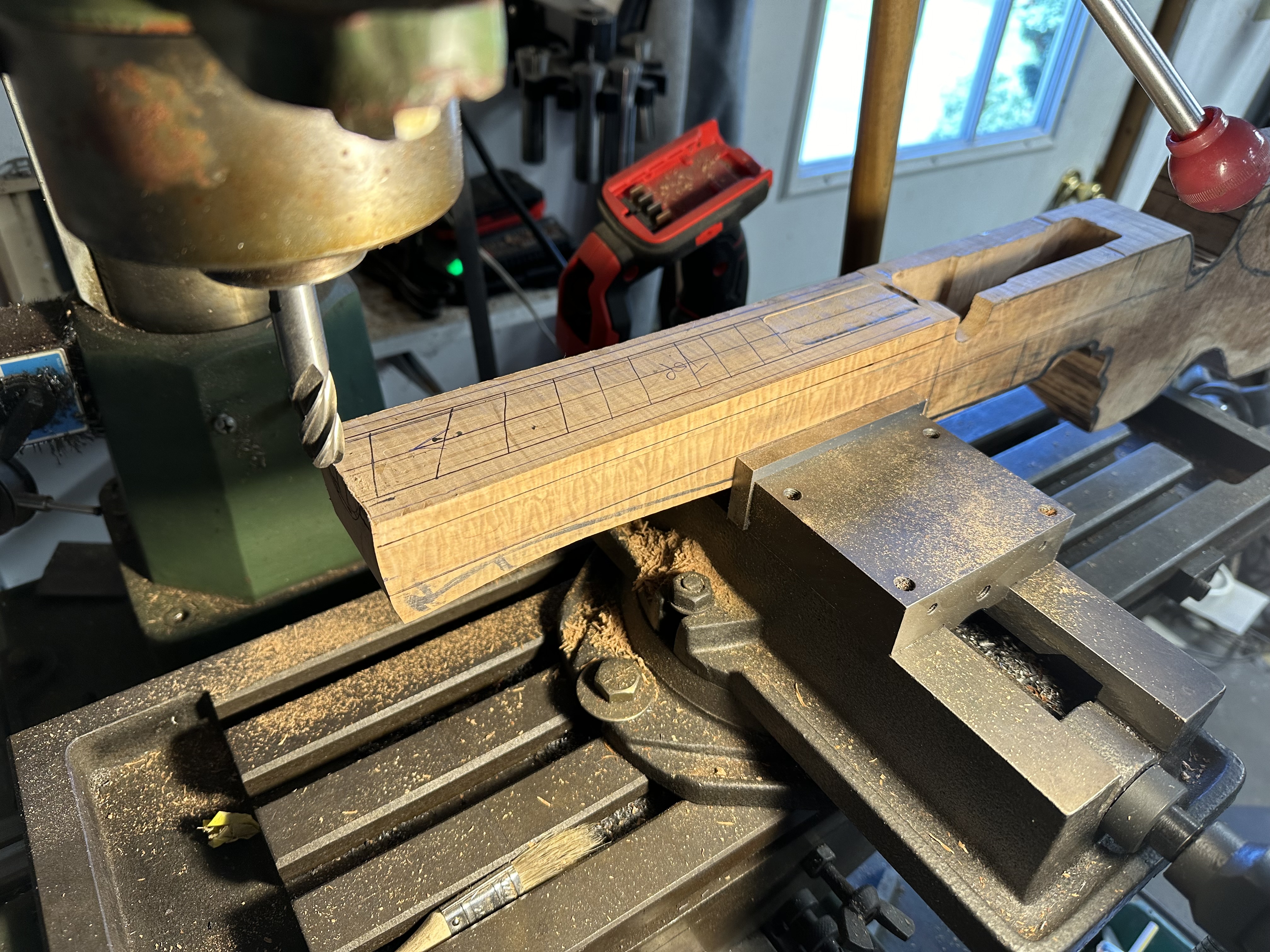

I couldn’t wait for the FX Walnut stocks and I had a little different idea of what I wanted my stock to look like . I have a GRS Dreamline which I I love the feel in hand every time I pick it up. But once you set the length of pull and the height of the comb it pretty much never gets changed for hunting purpose’s. I had a special curly maple stock blank I was given by a deceased friend that I was waiting for the right gun to stock with it. I laid out the pattern using elements of the GRS grip and the DRS cheek pad shape. Unfortunately when cutting away the perimeter I cut on the wrong line at the top of the forearm. I cut the line which represented the bottom of the barrel. Oh well I wasn’t going to throw this wood away so I glued it back the best I could and moved on. Inletting this action and barrel was so easy compared to most rifle actions being that it was all straight parallel lines, perfect to do in my vertical milling machine. I had it all done in about 3 hours. But next came the shaping. I used a grinding tool with an aggressive cupped wheel from Harbor Freight. Man that thing removes wood fast. The hardest thing I found in the whole process was final sanding. Maple wood is light in color so it does not show scratches . I had to stain it to reveal them and it took me along time of sanding to finally get them out. I left a reveal of 1/4” past the plentum which gives the rifle a look like a Rigby big bore rifle. I’m going to 3 D print or machine a floor plate for it . Im hoping that a medium size plentum is made for this platform . it is amazing how this stock has transformed this rifle from the synthetic stock . It looks and handles so differently. The wood was a soft silver maple which is light in weight. It only added 4 ounces over the synthetic stock. I used the recoil pad from the original stock. I’ll probably do a stippling pattern on the forearm later to hide the cement line along with something in the grip as well. These pictures are with only two coats of an oil finish. It will get another four or five more to properly fill to a glass smooth satin finish.

- The AGN App is ready! Search "Airgun Nation" in your App store. To compliment this new tech we've assigned the "Threads" Feed & "Dark" Mode. To revert back click HERE.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FX DRS wood stock project

- Thread starter Leatherman

- Start date

Yeah that is what the heart eyes is. Hold on the like button for options.This post makes me wish for a “Love” button. Just beautiful.

Upvote 0

Beautiful job Leatherman! Encouraging!

I have two curly Sugar Maple stock blanks, one is destined to be a sport stock for my FWB 300S and the other will likely end up on my DRS.

My combination lathe/mill doesn't have the reach to inlet the whole barrel channel so I've been machining the relief with on the tablesaw filing/sanding the steped cuts to the right radius. Works pretty well and is surprisingly fast to do.

I made a curly maple stock for my friend's Benjamin 392 and finished it with Aqua-Fortis and thinned urethane. Looks good!

Thanks for sharing the pictures - excellent work!

Cheers!

Hank

I have two curly Sugar Maple stock blanks, one is destined to be a sport stock for my FWB 300S and the other will likely end up on my DRS.

My combination lathe/mill doesn't have the reach to inlet the whole barrel channel so I've been machining the relief with on the tablesaw filing/sanding the steped cuts to the right radius. Works pretty well and is surprisingly fast to do.

I made a curly maple stock for my friend's Benjamin 392 and finished it with Aqua-Fortis and thinned urethane. Looks good!

Thanks for sharing the pictures - excellent work!

Cheers!

Hank

Upvote 0

That is freaking awesome. Very nice work. I like maple, but have no modern rifle stocked in it. But do have a few old American Longrifles stocked in tiger stripe maple.

Upvote 0

You replied to my dreamline thread today and told me about this stock so I had to check it out. It is a work of art! Thar maple has a lot of character. I have a woodworking background and I am also an artist. Some day I'd like to turn out a custom stock and then incorporate some wood burning art...I'll attach a sample of my art. Again, you created a very beautiful stock!I couldn’t wait for the FX Walnut stocks and I had a little different idea of what I wanted my stock to look like . I have a GRS Dreamline which I I love the feel in hand every time I pick it up. But once you set the length of pull and the height of the comb it pretty much never gets changed for hunting purpose’s. I had a special curly maple stock blank I was given by a deceased friend that I was waiting for the right gun to stock with it. I laid out the pattern using elements of the GRS grip and the DRS cheek pad shape. Unfortunately when cutting away the perimeter I cut on the wrong line at the top of the forearm. I cut the line which represented the bottom of the barrel. Oh well I wasn’t going to throw this wood away so I glued it back the best I could and moved on. Inletting this action and barrel was so easy compared to most rifle actions being that it was all straight parallel lines, perfect to do in my vertical milling machine. I had it all done in about 3 hours. But next came the shaping. I used a grinding tool with an aggressive cupped wheel from Harbor Freight. Man that thing removes wood fast. The hardest thing I found in the whole process was final sanding. Maple wood is light in color so it does not show scratches . I had to stain it to reveal them and it took me along time of sanding to finally get them out. I left a reveal of 1/4” past the plentum which gives the rifle a look like a Rigby big bore rifle. I’m going to 3 D print or machine a floor plate for it . Im hoping that a medium size plentum is made for this platform . it is amazing how this stock has transformed this rifle from the synthetic stock . It looks and handles so differently. The wood was a soft silver maple which is light in weight. It only added 4 ounces over the synthetic stock. I used the recoil pad from the original stock. I’ll probably do a stippling pattern on the forearm later to hide the cement line along with something in the grip as well. These pictures are with only two coats of an oil finish. It will get another four or five more to properly fill to a glass smooth satin finish.

View attachment 462515

View attachment 462516

View attachment 462518

View attachment 462519

View attachment 462522

View attachment 462523

View attachment 462524

View attachment 462525

View attachment 462526

View attachment 462528

View attachment 462529

View attachment 462531

Upvote 0

That is mind blowing. Amazing work!You replied to my dreamline thread today and told me about this stock so I had to check it out. It is a work of art! Thar maple has a lot of character. I have a woodworking background and I am also an artist. Some day I'd like to turn out a custom stock and then incorporate some wood burning art...I'll attach a sample of my art. Again, you created a very beautiful stock!View attachment 463568

Upvote 0

Now there's two amazing works of art in this thread! Very few people nowadays understand how to truly work with a piece of wood. You're both impressive craftsmen.

Upvote 0

Thanks guys. I need to add some panels of stippling on the fore arm and grip. The finish is too slick for a hunting gun. I’m thinking what I want to do for a while . Hate to cover that beautiful curl. I’ll come back with more pictures when I’m done. I’m thinking of getting amother DRS in .177 and will stock it in a more conventional style stock like the Minnelli stock that coming out but with a little different flare . I hope I influence some other guys to get a DRS and do their own wood stock. I have been influenced by some others who restocked their own Airguns. This DRS platform is perfect for this.

Upvote 0

Your shaping work and inletting work is great but that stock blank is even better. I've made a few stocks for my airguns but nothing in figured wood so far. Actually that's not completely true. I used pieces of the stump of my "killing tree" for my Prod stock and a nosepiece on my P35-25. But nothing like this.

Upvote 0

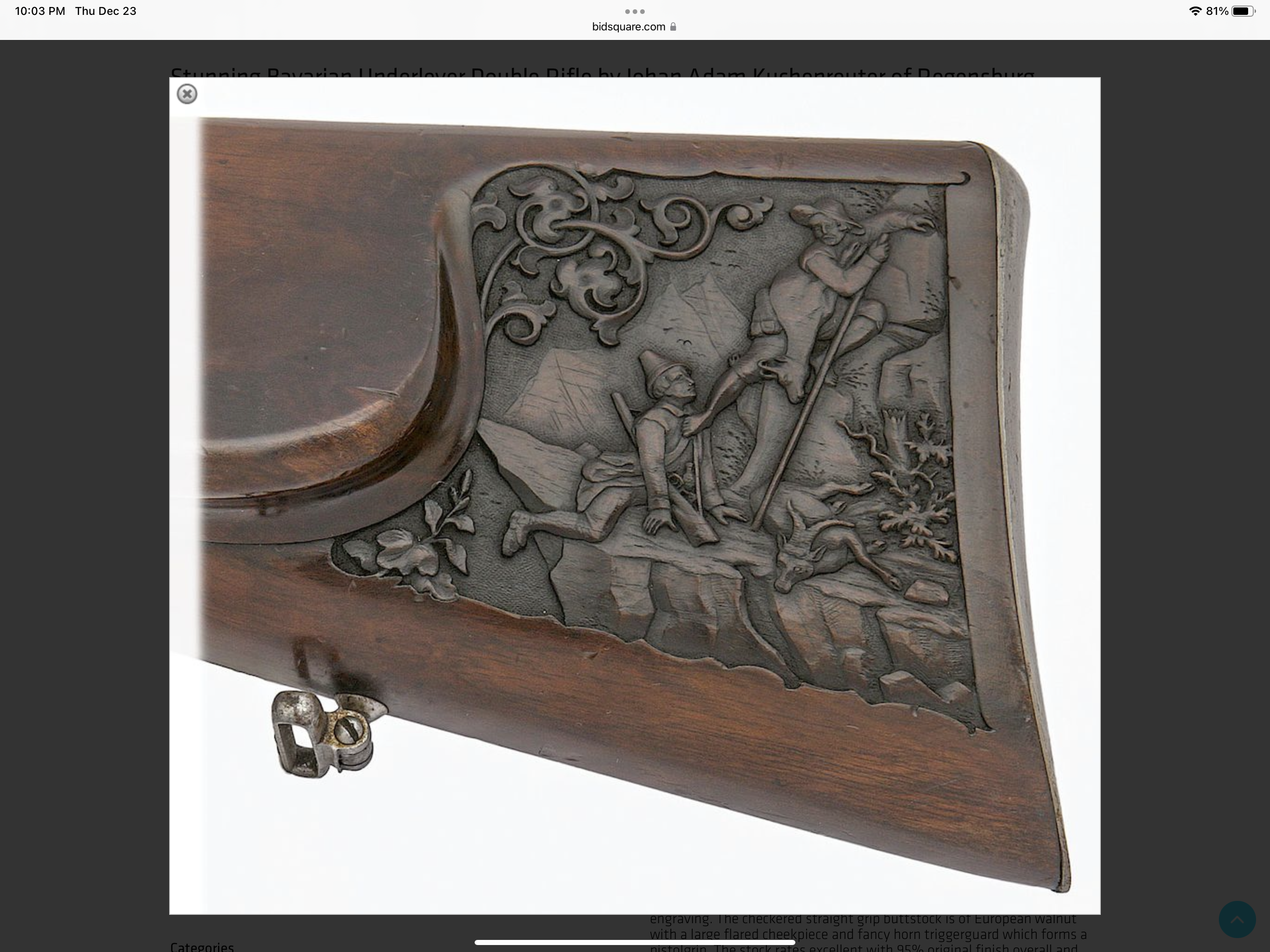

I have been thinking of doing a little carving art on my next project and maybe even some engraving in the action. I collect German sporting arms with high art on them. I can see an air gun with a squirrel , bird or groundhog carved into the stock. This type was popular in Europe pre WW2 era. Not so much in America. Here are some examples of different types of gun art.

Upvote 0

WOW!!I couldn’t wait for the FX Walnut stocks and I had a little different idea of what I wanted my stock to look like . I have a GRS Dreamline which I I love the feel in hand every time I pick it up. But once you set the length of pull and the height of the comb it pretty much never gets changed for hunting purpose’s. I had a special curly maple stock blank I was given by a deceased friend that I was waiting for the right gun to stock with it. I laid out the pattern using elements of the GRS grip and the DRS cheek pad shape. Unfortunately when cutting away the perimeter I cut on the wrong line at the top of the forearm. I cut the line which represented the bottom of the barrel. Oh well I wasn’t going to throw this wood away so I glued it back the best I could and moved on. Inletting this action and barrel was so easy compared to most rifle actions being that it was all straight parallel lines, perfect to do in my vertical milling machine. I had it all done in about 3 hours. But next came the shaping. I used a grinding tool with an aggressive cupped wheel from Harbor Freight. Man that thing removes wood fast. The hardest thing I found in the whole process was final sanding. Maple wood is light in color so it does not show scratches . I had to stain it to reveal them and it took me along time of sanding to finally get them out. I left a reveal of 1/4” past the plentum which gives the rifle a look like a Rigby big bore rifle. I’m going to 3 D print or machine a floor plate for it . Im hoping that a medium size plentum is made for this platform . it is amazing how this stock has transformed this rifle from the synthetic stock . It looks and handles so differently. The wood was a soft silver maple which is light in weight. It only added 4 ounces over the synthetic stock. I used the recoil pad from the original stock. I’ll probably do a stippling pattern on the forearm later to hide the cement line along with something in the grip as well. These pictures are with only two coats of an oil finish. It will get another four or five more to properly fill to a glass smooth satin finish.

View attachment 462515

View attachment 462516

View attachment 462518

View attachment 462519

View attachment 462522

View attachment 462523

View attachment 462524

View attachment 462525

View attachment 462526

View attachment 462528

View attachment 462529

View attachment 462531

Upvote 0