Firstly, thank you Ernest for your excellent videos. These make repair jobs for novices like me relatively easy along with some decent tools.

Impact developed a slow leak a few weeks however a few days back when I reconnected the bottle, there was a heavy leak coming from the gap next to the power adjustment wheel. At first I assumed it was the leak from the regulator so pulled it all apart and replaced all the o-rings in there. The two 2x1nbr90 o-rings on the adjustment nut were a nightmare to get on, broke 20+ in the process until I figured the right way to get them on! Rest of the o-rings were easy. Leak persisted so decided to disassemble the whole thing to replace the rest of the o-rings on and around the valve stem. There goes the warranty in the bin but hey-ho!

If you done a bit of car servicing or house DIY and are good with tools, all this should be straight forward. One a scale of 1-10 (10 being extremely difficult), this is around 3-4 imo. I say 3-4 because of the regulator adjustment nut o-rings. Otherwise it would be 2-3.

Tools needed:

0.9mm Hex Key (for grub screw on the hammerseat)*

2.5mm Hex Key (for most screws)

4mm Hex Key (for picatinny rail, valve-tube nut, rear block grub screw)

8mm Hex Key (for grip nut)

11mm Wrench (valve adjuster screw)

8mm Wrench (quad o-ring stop screw)

Rubber strap wrench (valvehouse)

Brass (or steel if you are daring) O-ring Pick set

Good quality lube

Small torch

* Ordered 1mm hex key as per Ernest but it didn't fit. Maybe FX changed this to 0.9mm in later production.

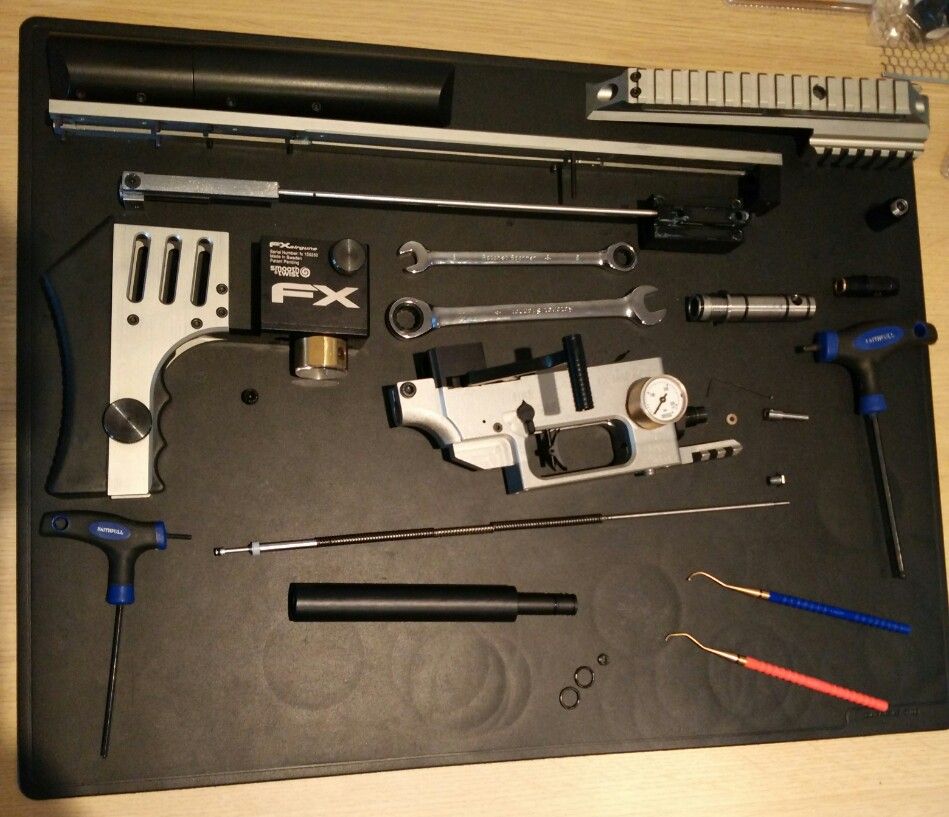

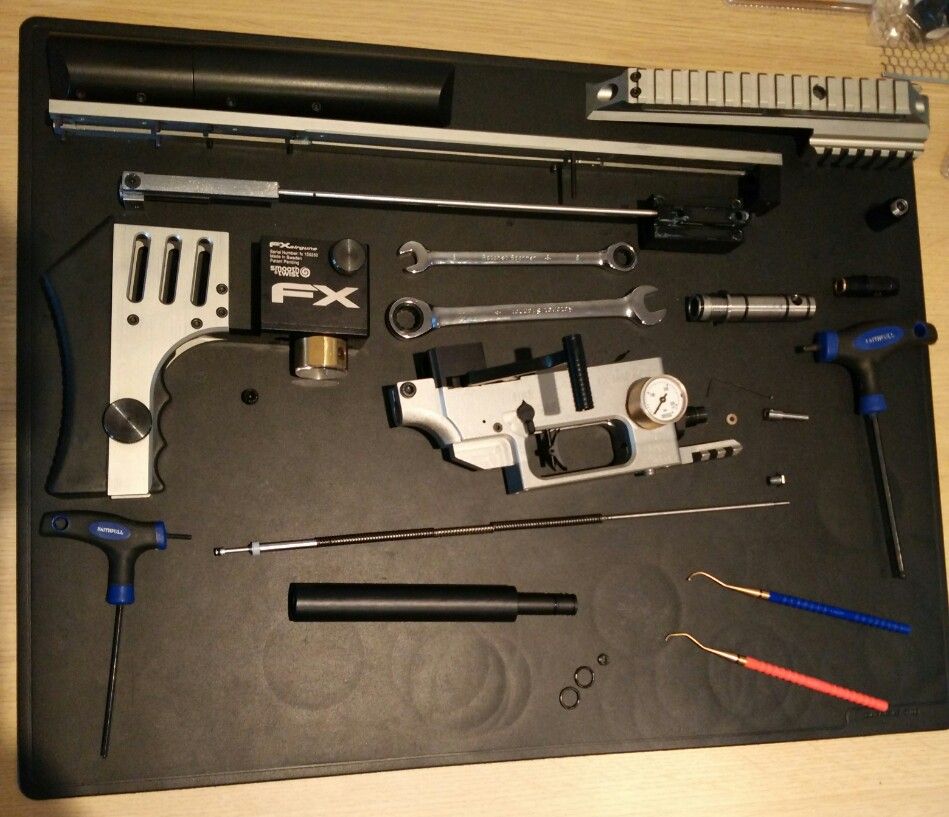

Everything apart:

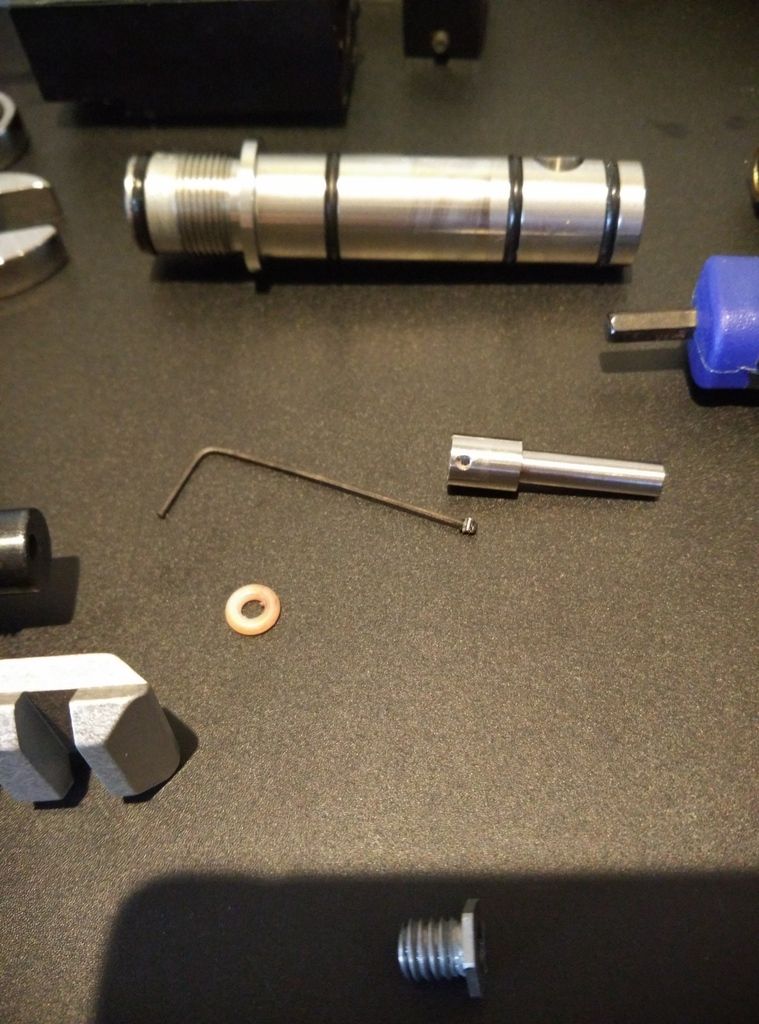

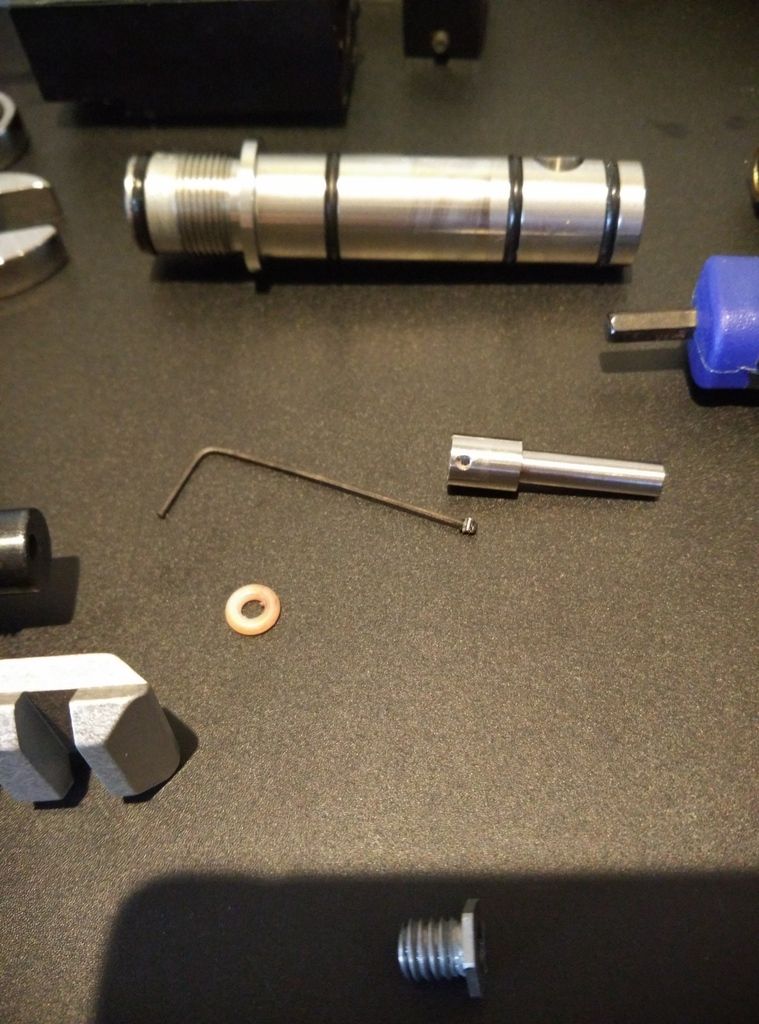

Valve tube o-rings and quad ring:

Hammerseat:

Valvestem: Main stem is threaded on both ends so it can be screwed off from the rear block side and pulled out from the valve adjustment side, if removing the hammerseat grub screw becomes an issue. Light loctite from factory on both ends.

How to's (by Ernest):

Disassembly 1: Disassembly 2: Reassembly 1: Reassembly 2:

The only thing I did different upon reassembly is to to tighten the screws on the main plate and the 4mm valve tube screw only after inserting the barrel (for complete alignment). FX could have designed the front barrel bushing in a different way so that it slots in plate instead of having play in the screw holes. Hence inserting the barrel before tightening everything down is probably a good idea.

Impact developed a slow leak a few weeks however a few days back when I reconnected the bottle, there was a heavy leak coming from the gap next to the power adjustment wheel. At first I assumed it was the leak from the regulator so pulled it all apart and replaced all the o-rings in there. The two 2x1nbr90 o-rings on the adjustment nut were a nightmare to get on, broke 20+ in the process until I figured the right way to get them on! Rest of the o-rings were easy. Leak persisted so decided to disassemble the whole thing to replace the rest of the o-rings on and around the valve stem. There goes the warranty in the bin but hey-ho!

If you done a bit of car servicing or house DIY and are good with tools, all this should be straight forward. One a scale of 1-10 (10 being extremely difficult), this is around 3-4 imo. I say 3-4 because of the regulator adjustment nut o-rings. Otherwise it would be 2-3.

Tools needed:

0.9mm Hex Key (for grub screw on the hammerseat)*

2.5mm Hex Key (for most screws)

4mm Hex Key (for picatinny rail, valve-tube nut, rear block grub screw)

8mm Hex Key (for grip nut)

11mm Wrench (valve adjuster screw)

8mm Wrench (quad o-ring stop screw)

Rubber strap wrench (valvehouse)

Brass (or steel if you are daring) O-ring Pick set

Good quality lube

Small torch

* Ordered 1mm hex key as per Ernest but it didn't fit. Maybe FX changed this to 0.9mm in later production.

Everything apart:

Valve tube o-rings and quad ring:

Hammerseat:

Valvestem: Main stem is threaded on both ends so it can be screwed off from the rear block side and pulled out from the valve adjustment side, if removing the hammerseat grub screw becomes an issue. Light loctite from factory on both ends.

How to's (by Ernest):

Disassembly 1:

The only thing I did different upon reassembly is to to tighten the screws on the main plate and the 4mm valve tube screw only after inserting the barrel (for complete alignment). FX could have designed the front barrel bushing in a different way so that it slots in plate instead of having play in the screw holes. Hence inserting the barrel before tightening everything down is probably a good idea.