So, I and a few friends and acquaintances got our Delta Wolf HP'S in 0.22 around early July from the first SA shipment with much excitement... And every single one of us was horribly disappointed.

Especially for me, the gun was both the most expensive and the absolute worst shooting rifle I had ever experienced, despite having a wonderful trigger and shot cycle as well as producing superbly consistent velocities (despite some genuinely beta level software at present) particularly in advanced mode.

I suppose the near complete lack of coverage of the 0.22 DW should have rung a few bells. And if you look back at Matt Mannings review his group was completely subpar with shots stringing diagonally. Only Richard Saunders/Alpha Militaria seems to have managed to show one decent group on camera with 25gr redesigns.

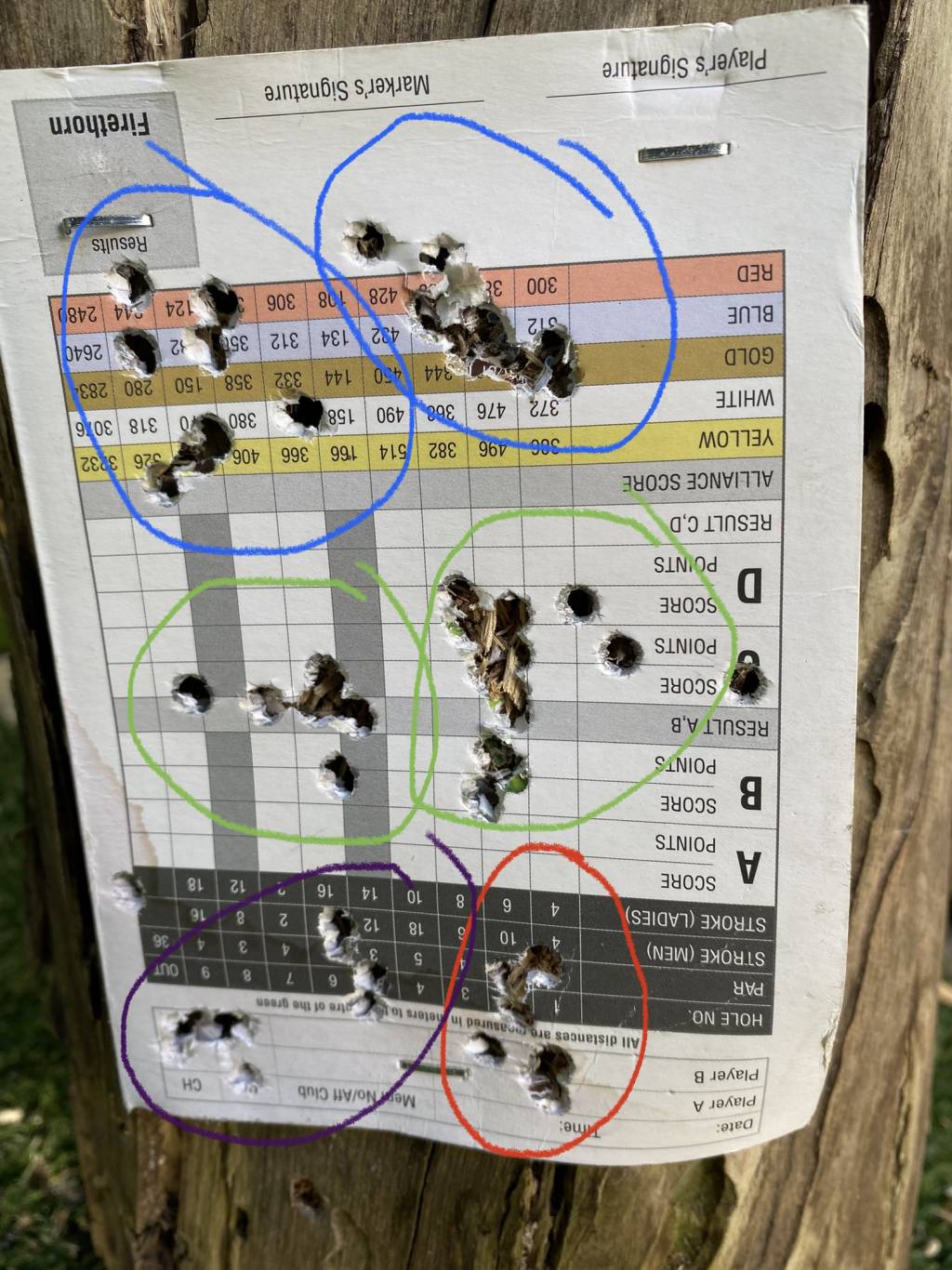

Now I can say with absolute conviction that the gun is magnificently designed and engineered from the bottle to the transfer port, with near edgun level rigidity of the frame. Yet it still produced 'groups' like this at 20m regardless of pellet or velocity (excuse the first target- it was shot at my parents place):

And scattershot like this with the best performing 20m pellet and velocity at 50m:

These groups remained unchanged whether the moderator was on or off the gun (I ran some risks with the neighbors firing this thing off without one as in stock form the shroud does not do a thing). I was ready to send the gun back and initially I actually did, but curiosity and a need to know why got the better of me, along with the suspicion it would be a long long wait until anything got sorted out, so I asked for the gun back to run some tests.

I was initially completely convinced we'd all somehow received out of spec barrels from LW in out batch of Delta's and so contacted everyone I knew with a gun to check their twist rates and chokes as well as see if their barrels had tight spots or burrs etc, but as it turns out the barrels are actually okay, albeit so unbelievably pellet and velocity fussy that they just about completely negate to usefulness of all the tuneability of the gun. Shooting completely bare barrel with the chrony removed and disabled in the software (following setup with 25gr to similar velocities to an HP Red wolf) improved things significantly too.

So that left the shroud and chrony setup. In stock form the chrony connects directly to the end of the barrel via an M14x1 muzzle thread. The chrony has four very small holes (see the below pic) that lie just about flush to the edge of the muzzle when the chrony is threaded on fully. This is the only connection between muzzle and the rest of the shroud. Thereafter the closed ~10mm diameter and roughly 10cm long closed chrony tube begins, ending approximately 5mm from shrouds large m20 endcap. The result is virtually no air stripping and hence the megaphone like effect of the shroud which makes the gun so loud.

The other issue I noticed is the shroud support. The collar that houses the chrony connector is firmly attached to the barrel via grubs screws. The CF shroud slips over this and is held in place by two further grub screws, that only provide forward back and rotational stability, but don't clamp the shroud down firmly at all. Not a big deal but unfortunately the only forward support for the shroud is orings around the flexible plastic chrony itself, resulting in some quite significant 'whip and wobble' in the shroud during the shot cycle.

So figured given the apparent absence of any other design flaws it was likely some combination of the above causing the issues. To my mind the most likely reason being massive turbulence caused by the long chrony tube funneling the muzzle blast into the pellet path. Especially as most people that I've spoken to that have had any luck at all getting theirs to shoot straight have said that the higher the reg pressure, the better, presumably since the valve can then close much sooner and reduce muzzle blast for a given velocity.

While considering finding and machining a new LW barrel I happened to notice that the breech ends of the Delta Wolf and FX barrels are virtually identical.

All it took was to polish 0.015mm off the brass port and the bands on the silver colored steel part of the fx barrel and it fit like a glove. Didn't even need to remove the FX orings.

Because the FX barrel is 14mm OD vs the original barrels 15mm I initially 3d printed a small collar to ensure it was centered and snug at the front part of the frame.

Shooting bare barrel at 30m the results were instantaneous with tiny one hole full mag groups. And the best bit was I didn't lose any velocity with the 500mm barrel I used at all compared to the stock 590mm barrel, presumably mostly because of the larger transfer port. So, iffy barrel sorted.

I had a 1/2inch unf to m14 adapter machined (using a 500mm barrel was necessary to have enough space in the OEM shroud for this) along with making 3d printed bushings for the shroud/chrony collar and reassembled, and found the groups were back to being poor.

So I had a friend machine a new adapter that was also an air stripper, with the baffle part also supporting the shroud instead of the chrony. By happy accident he also discovered that a 15mm OD copper plumbing pipe perfectly fits over the fx barrel, making it a perfect match externally to the OEM barrel.

Anyway after hating the gun and wanting to throw it in the river, the results have been spectacular. Below is a full mag at 30m and it's confirmed effortlessly sub moa out to 120m, which is as far as I've had a chance to shoot so far as it's incredibly windy at the moment. It's virtually impossible to get this gun to do anything but drill holes now, plus I get the versatility of the different liners.

Fringe benefits of all this are a massive reduction in muzzle report now that there is an air stripper in there and the shroud is being used effectively, as well as fact that I haven't had to clean the chrony tube in well over 1500 shots.

Of course I should never have had to do all this on the 'world's most advanced airgun' but it is a very new platform and it's pretty easy to forget the huge amount of work and myriad upgrades it took to get my and many others' impacts to the level they are at now. And the delta is already shooting at the same level.

It seems to me that the Delta Wolves that shoot really well stock (and get actual youtube/social media coverage) are the sub 12 0.177 and the 30cals. I can only guess it's because the former has so little air behind the pellet that turbulence isn't much of an issue, and that the latter hurls such big heavy chunks of lead that their shear inertia may just shrug it off? As far as I can see the 0.25's also seem to strongly prefer the heavier jsb's, just maybe since they can also shrug off that muzzle blast? Of course they're also seemingly limited to the no longer available mk1 too, which is likely barrel related. So this could be useful for them too for that reason.

Anyway I'm very happy with my Delta Wolf now and hopefully this might help anyone that's struggling with theirs but can still see the potential. It took a while to get right but now I know how it's actually a very quick and easy solution.

My next plan is to install a superior heavy liner, a dual transfer port and change the stock probe to a pin probe, just to see what gains there may be. It never ends

Cheers!

Especially for me, the gun was both the most expensive and the absolute worst shooting rifle I had ever experienced, despite having a wonderful trigger and shot cycle as well as producing superbly consistent velocities (despite some genuinely beta level software at present) particularly in advanced mode.

I suppose the near complete lack of coverage of the 0.22 DW should have rung a few bells. And if you look back at Matt Mannings review his group was completely subpar with shots stringing diagonally. Only Richard Saunders/Alpha Militaria seems to have managed to show one decent group on camera with 25gr redesigns.

Now I can say with absolute conviction that the gun is magnificently designed and engineered from the bottle to the transfer port, with near edgun level rigidity of the frame. Yet it still produced 'groups' like this at 20m regardless of pellet or velocity (excuse the first target- it was shot at my parents place):

And scattershot like this with the best performing 20m pellet and velocity at 50m:

These groups remained unchanged whether the moderator was on or off the gun (I ran some risks with the neighbors firing this thing off without one as in stock form the shroud does not do a thing). I was ready to send the gun back and initially I actually did, but curiosity and a need to know why got the better of me, along with the suspicion it would be a long long wait until anything got sorted out, so I asked for the gun back to run some tests.

I was initially completely convinced we'd all somehow received out of spec barrels from LW in out batch of Delta's and so contacted everyone I knew with a gun to check their twist rates and chokes as well as see if their barrels had tight spots or burrs etc, but as it turns out the barrels are actually okay, albeit so unbelievably pellet and velocity fussy that they just about completely negate to usefulness of all the tuneability of the gun. Shooting completely bare barrel with the chrony removed and disabled in the software (following setup with 25gr to similar velocities to an HP Red wolf) improved things significantly too.

So that left the shroud and chrony setup. In stock form the chrony connects directly to the end of the barrel via an M14x1 muzzle thread. The chrony has four very small holes (see the below pic) that lie just about flush to the edge of the muzzle when the chrony is threaded on fully. This is the only connection between muzzle and the rest of the shroud. Thereafter the closed ~10mm diameter and roughly 10cm long closed chrony tube begins, ending approximately 5mm from shrouds large m20 endcap. The result is virtually no air stripping and hence the megaphone like effect of the shroud which makes the gun so loud.

The other issue I noticed is the shroud support. The collar that houses the chrony connector is firmly attached to the barrel via grubs screws. The CF shroud slips over this and is held in place by two further grub screws, that only provide forward back and rotational stability, but don't clamp the shroud down firmly at all. Not a big deal but unfortunately the only forward support for the shroud is orings around the flexible plastic chrony itself, resulting in some quite significant 'whip and wobble' in the shroud during the shot cycle.

So figured given the apparent absence of any other design flaws it was likely some combination of the above causing the issues. To my mind the most likely reason being massive turbulence caused by the long chrony tube funneling the muzzle blast into the pellet path. Especially as most people that I've spoken to that have had any luck at all getting theirs to shoot straight have said that the higher the reg pressure, the better, presumably since the valve can then close much sooner and reduce muzzle blast for a given velocity.

While considering finding and machining a new LW barrel I happened to notice that the breech ends of the Delta Wolf and FX barrels are virtually identical.

All it took was to polish 0.015mm off the brass port and the bands on the silver colored steel part of the fx barrel and it fit like a glove. Didn't even need to remove the FX orings.

Because the FX barrel is 14mm OD vs the original barrels 15mm I initially 3d printed a small collar to ensure it was centered and snug at the front part of the frame.

Shooting bare barrel at 30m the results were instantaneous with tiny one hole full mag groups. And the best bit was I didn't lose any velocity with the 500mm barrel I used at all compared to the stock 590mm barrel, presumably mostly because of the larger transfer port. So, iffy barrel sorted.

I had a 1/2inch unf to m14 adapter machined (using a 500mm barrel was necessary to have enough space in the OEM shroud for this) along with making 3d printed bushings for the shroud/chrony collar and reassembled, and found the groups were back to being poor.

So I had a friend machine a new adapter that was also an air stripper, with the baffle part also supporting the shroud instead of the chrony. By happy accident he also discovered that a 15mm OD copper plumbing pipe perfectly fits over the fx barrel, making it a perfect match externally to the OEM barrel.

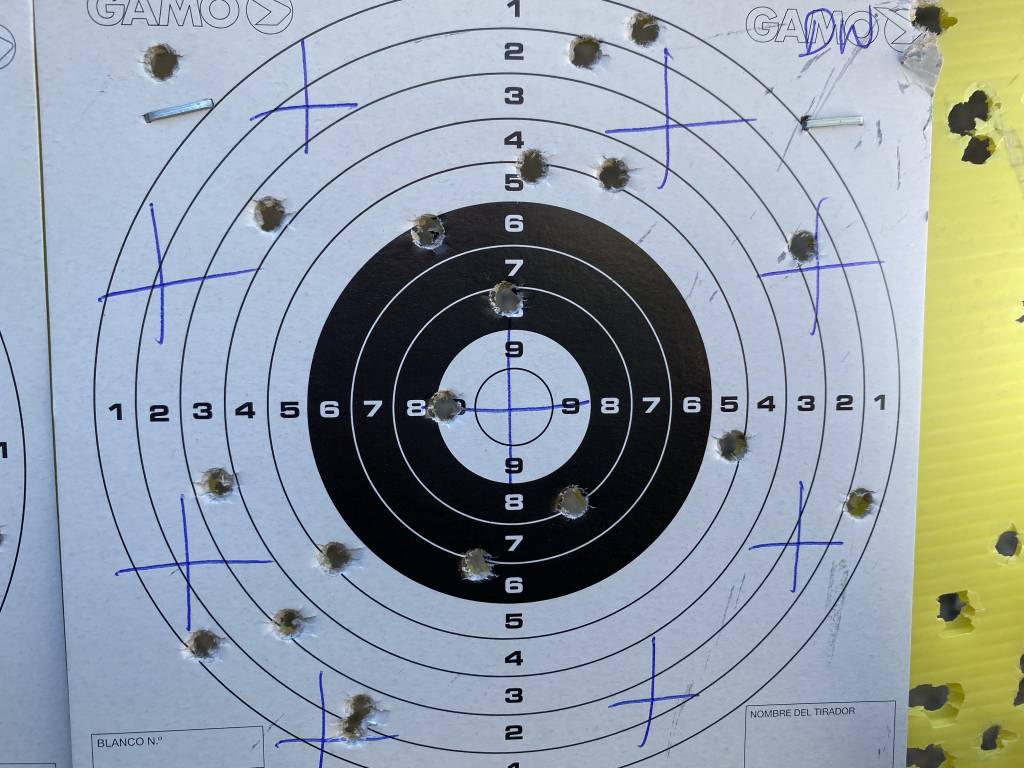

Anyway after hating the gun and wanting to throw it in the river, the results have been spectacular. Below is a full mag at 30m and it's confirmed effortlessly sub moa out to 120m, which is as far as I've had a chance to shoot so far as it's incredibly windy at the moment. It's virtually impossible to get this gun to do anything but drill holes now, plus I get the versatility of the different liners.

Fringe benefits of all this are a massive reduction in muzzle report now that there is an air stripper in there and the shroud is being used effectively, as well as fact that I haven't had to clean the chrony tube in well over 1500 shots.

Of course I should never have had to do all this on the 'world's most advanced airgun' but it is a very new platform and it's pretty easy to forget the huge amount of work and myriad upgrades it took to get my and many others' impacts to the level they are at now. And the delta is already shooting at the same level.

It seems to me that the Delta Wolves that shoot really well stock (and get actual youtube/social media coverage) are the sub 12 0.177 and the 30cals. I can only guess it's because the former has so little air behind the pellet that turbulence isn't much of an issue, and that the latter hurls such big heavy chunks of lead that their shear inertia may just shrug it off? As far as I can see the 0.25's also seem to strongly prefer the heavier jsb's, just maybe since they can also shrug off that muzzle blast? Of course they're also seemingly limited to the no longer available mk1 too, which is likely barrel related. So this could be useful for them too for that reason.

Anyway I'm very happy with my Delta Wolf now and hopefully this might help anyone that's struggling with theirs but can still see the potential. It took a while to get right but now I know how it's actually a very quick and easy solution.

My next plan is to install a superior heavy liner, a dual transfer port and change the stock probe to a pin probe, just to see what gains there may be. It never ends

Cheers!