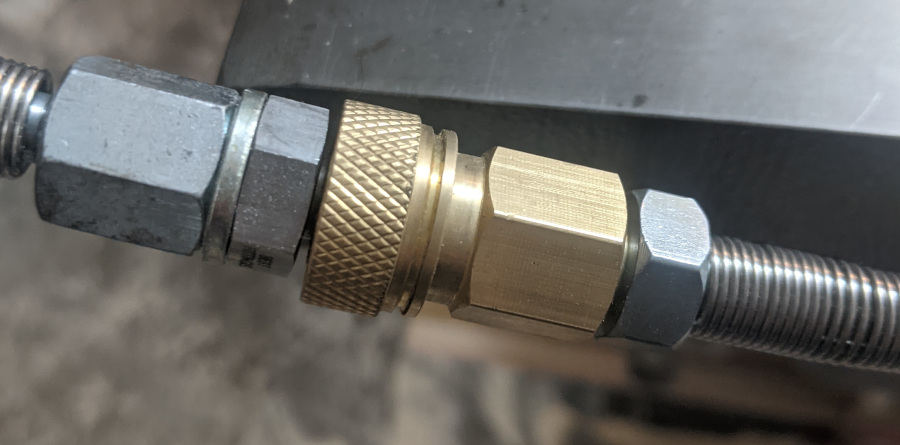

I recently had an o-ring for a foster fitting fail -- in the female 1/8" BSPP fitting in the image below.

I did some searching on the forum and all the advice was for buna-n AS568-10 o-rings.

But I have some of those, and they're far from what I need. My o-rings need to be 3/32" thick, but the -10 o-rings are 1/16" thick.

So I ordered some -105 and -106's. Probably both of them will do the job but hopefully I'll discover what the proper o-ring size is for my foster fittings.

I did some searching on the forum and all the advice was for buna-n AS568-10 o-rings.

But I have some of those, and they're far from what I need. My o-rings need to be 3/32" thick, but the -10 o-rings are 1/16" thick.

So I ordered some -105 and -106's. Probably both of them will do the job but hopefully I'll discover what the proper o-ring size is for my foster fittings.