Fresh cast and sized to .457....NOE 458-244 four cavity mold.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

N/A Who's Casting or Wants to Learn?

- Thread starter RM.510bigbore

- Start date

.30 cal 55gr HP Eastwood # 10343 COPPER METALLIC which looks like it may have been discontinued. :-(

Upvote 0

Same .30 cal, same powder....it didn't flow out as nice on the the big round a .58 cal. 435 grain.

Upvote 0

I've got a bottle of Eastwood Copper Vein that I don't really care for. It looks good mixed with other colors though. The one on the left is Copper Vein and the right is Copper Vein mixed with Cardinal Hammer White.

Upvote 0

How much power coating buildup is added to a sized slug? .001, .002, etc?I've got a bottle of Eastwood Copper Vein that I don't really care for. It looks good mixed with other colors though. The one on the left is Copper Vein and the right is Copper Vein mixed with Cardinal Hammer White.

View attachment 425072

Upvote 0

It's usually about .001 when I shake and bake. I start with a small amount of powder and only add more if I don't have good coverage.How much power coating buildup is added to a sized slug? .001, .002, etc?

Upvote 0

Some of the copper colors just don't cover well. It is like there is just not enough solids in the powder and they separate out and don't flow with the clear resins.

Upvote 0

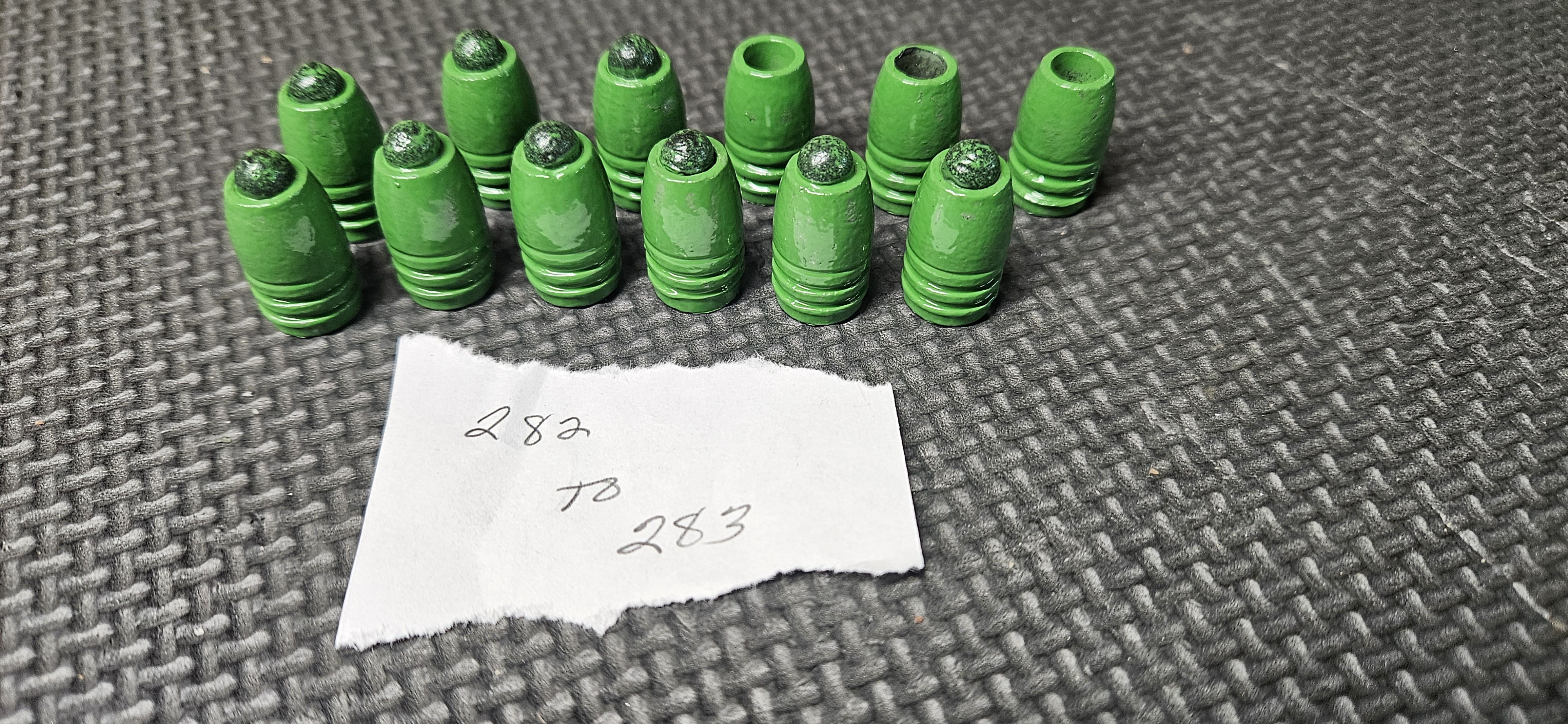

Here's some I did today John Deer green from a guy on Castbooits Gunloads. They didn't turn out as nice as they usually do but they'll shoot just the same.

Upvote 0

Are those out of NOE 460-315-RFAV3 mold?Here's some I did today John Deer green from a guy on Castbooits Gunloads. They didn't turn out as nice as they usually do but they'll shoot just the same.

View attachment 425603

They look good!

Upvote 0

Yes that is the mold I have the double cavity mold they shoot great in my Texan and I had planned on sizing them down to .454 to shoot in my XP Ranger just never got around to doing it. I cast these the other day and coated them to shoot out of a Quackenbush Outlaw 457 that Bob Dean had tuned just waited on the weather to get better to try them.Are those out of NOE 460-315-RFAV3 mold?

They look good!

Upvote 0

Ya the weather needs to get a WHOLE lot better....Colder than a well diggers toes right now.

Upvote 0

Same .30 cal, same powder....it didn't flow out as nice on the the big round a .58 cal. 435 grain.

View attachment 425069Try baking the larger boolits a little longer next time to help compensate for the larger thermal mass.

Upvote 0

I did give them a longer bake time with the additional mass to heat up, I even gave them a second bake still not much better.

Last edited:

Upvote 0

Did some lead reclamation today.

Cleaned the trap so I could install this big boy in the back of the box. A 20" x 1/2" AR500 gong. Something a for a little extra to insure stopping the .58 Cal from the Zeus. Box is 24" square x 12" deep filled with rubber mulch. It has stopped .457 Texan but it is driving slugs near the rear.

Cleaned the trap so I could install this big boy in the back of the box. A 20" x 1/2" AR500 gong. Something a for a little extra to insure stopping the .58 Cal from the Zeus. Box is 24" square x 12" deep filled with rubber mulch. It has stopped .457 Texan but it is driving slugs near the rear.

Upvote 0

The box is filled

The box is packed full of rubber mulch. The projectile should be pretty slow by the time it hits the AR500 plate if it even reaches it and the mulch would also take up any ricochet energy.@Loren I angle all the AR500 plates in my indoor boxes and have to put a plate on the bottom as well - not sure how ricochets will work with the plate verticl

Upvote 0

The box is filled

The box is packed full of rubber mulch. The projectile should be pretty slow by the time it hits the AR500 plate if it even reaches it and the mulch would also take up any ricochet energy.

That's true, I forget that I only burry my plate about 2" deep so the mulch doesn't absorb much but I still get the satisfying sound of the steel.

Upvote 0

@Loren I have some questions about your lead reclamation process and recycling/casting process.

1) Does melting powder coated slugs smell particularly awful? Does it smoke significantly more than non-coated slugs?

2) How do you separate you lead from the rubber mulch?

3) Does the lead separated from the rubber mulch smell awful when you melt it down? If so, what do you do differently to help deal with the burnt rubber smell as far as ventilation is concerned?

I've read of others' experiences and I'm curious about yours. I'm not sure if I read anything you posted on the topic elsewhere. If you've answered these questions elsewhere, please point me in the right direction and I'll go and re-read your posts.

1) Does melting powder coated slugs smell particularly awful? Does it smoke significantly more than non-coated slugs?

2) How do you separate you lead from the rubber mulch?

3) Does the lead separated from the rubber mulch smell awful when you melt it down? If so, what do you do differently to help deal with the burnt rubber smell as far as ventilation is concerned?

I've read of others' experiences and I'm curious about yours. I'm not sure if I read anything you posted on the topic elsewhere. If you've answered these questions elsewhere, please point me in the right direction and I'll go and re-read your posts.

Upvote 0

Here is all the lead from the trap.

It is nearly 30 lbs.

I only do melting of this lead outside or on my industrial spray booth bench with a 12" exhaust duct which is sucking 100% of the fumes/ smoke outside.

If any rubber is left it STINKS... it is basically shredded tires and the PC is nothing you want in your lungs either. The PC is most of the time a polyester resin, so think of a burning leisure suit...lol

I hand sift through the mulch while using a large shop vac with a cyclone separator on it to drop out the mulch and let the very small fines go into the vacuum canister.

The bright PC colors really help with the sifting. It is tedious but it works and is not real messy.

I tried the water separation once and it was a FAIL. The rubber is dense and not all of it floats so I still ended up hand sifting and now everything is wet and a mess.

It is nearly 30 lbs.

I only do melting of this lead outside or on my industrial spray booth bench with a 12" exhaust duct which is sucking 100% of the fumes/ smoke outside.

If any rubber is left it STINKS... it is basically shredded tires and the PC is nothing you want in your lungs either. The PC is most of the time a polyester resin, so think of a burning leisure suit...lol

I hand sift through the mulch while using a large shop vac with a cyclone separator on it to drop out the mulch and let the very small fines go into the vacuum canister.

The bright PC colors really help with the sifting. It is tedious but it works and is not real messy.

I tried the water separation once and it was a FAIL. The rubber is dense and not all of it floats so I still ended up hand sifting and now everything is wet and a mess.

I'm almost there. I don't have the equipment but do have questions.

Does the powder coat prevent recycling the metal repeatedly? Or is it a slag thats removed cleanly during the melt?

Does anyone have a link to a casting equipment build, or better yet, does anyone have spare equipment? A melter or molds?

Does the powder coat prevent recycling the metal repeatedly? Or is it a slag thats removed cleanly during the melt?

Does anyone have a link to a casting equipment build, or better yet, does anyone have spare equipment? A melter or molds?

Upvote 0