I shoot a western rattler .357 and it’s a powerful gun. It jumps around a lot when fired. ( over 200 ft lbs at muzzle) I just did something tonight that changed my air rifle into a much better vehicle. It cost me $25 and didn’t I even need epoxy.

After considering carbon fiber sleeves to stiffen up my flimsy (15mm OD) TJ Max barrel, I ended up choosing a steel option instead. I chose steel because it’s heavier, not stiffer. My knowledge in centerfire pointed me in this direction because I learned that SLOWING down BARREL vibration YIELDS bigger load windows and makes more consistent exit timing. A slower vibration leads to better repeatability. Thanks Eric Cortina!

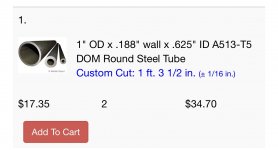

I ordered a piece of steel tubing from metal depot, cut to length. 1” OD, .188” wall thickness. My sleeve slipped over my barrel with ease because it’s .034” larger ( or about 4 times the thickness of electrical tape ) than my 15mm barrel, so I slipped it over my TJ barrel and spaced it with double thickness electrical tape at two spots . The new sleeve slipped over my barrel snugly after spacing with electrical tape.

I took the gun outside and it stacked slugs at 100 yards from a tripod, high barricade standing position. No recoil issues, no muzzle rise nor did I need to shoulder the rifle to mitigat recoil. The gun went from 4” groups at 50 yards on a bench with sand bags to hitting a squirrel size plate 9 of 10 times at 100 standing from a high tripod.

Now when I shoot this rifle, it doesn’t kick like a mule.

I also blued the barrel to make it pretty and now it’s less likely to rust.

My recommendation , don’t use carbon, go with steel for extra weight. Slow the hormonics down and don’t overthink epoxy. I just did this in an hour and $25 no epoxy.

View attachment 500569 View attachment 500565View attachment 500566View attachment 500567 View attachment 500568