I bought a Hatsan brand regulator for $48.00 off of Amazon and found out it wasn't as bad as everyone says it is, but it IS plagued by a lack of information on how to install it and it's capabilities.

Where the Confusion Starts

First off Hatsan, like many companies, is constantly iterating over the same designs. What this means is that an AT44 bought in 2019 is different from an AT44 from 2018 and very different from one back in 2014. Many of these changes are minor improvements like pre-drilling holes in the stock to allow hammer throw adjustment without stock removal. Others are cost cutting changes that improve profits but can reduce reliability. Luckily the AT44 platform is very simple and mostly free from these cost-cutting changes or at least not impacted so much from them. The point is, the main change causing confusion is the change in valve design. There is a non-H class air tube and an H class air tube.

The Non-H class (classic) air tube looks like this:

The H class (newer) air tube looks like this:

With the changes to the air tube design there also came several iterations to the valve which is the most important. If you buy the wrong air tube and put it on the wrong gun you're going to have a bad time. This is the first concern. If you add a regulator to the mix it makes things even worse... so, the changes were so much so that they had to produce two different regulators to account for these design shifts.

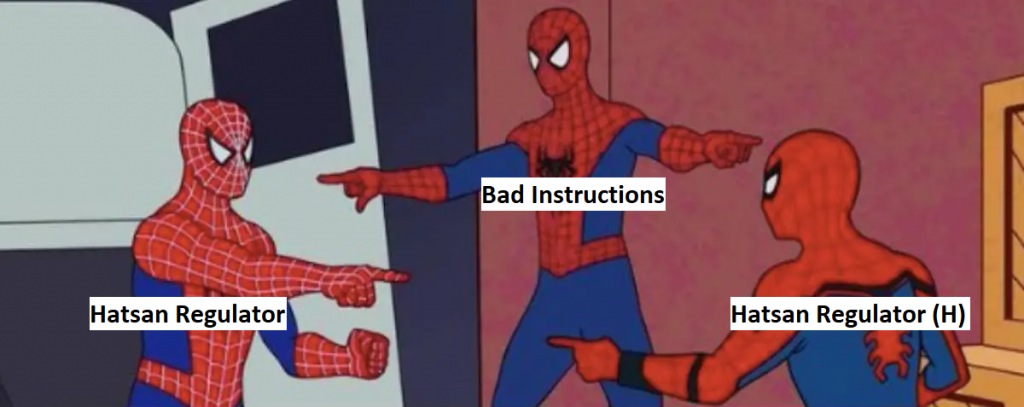

Hatsan Regulator vs H-Class Hatsan Regulator vs The Install Instructions

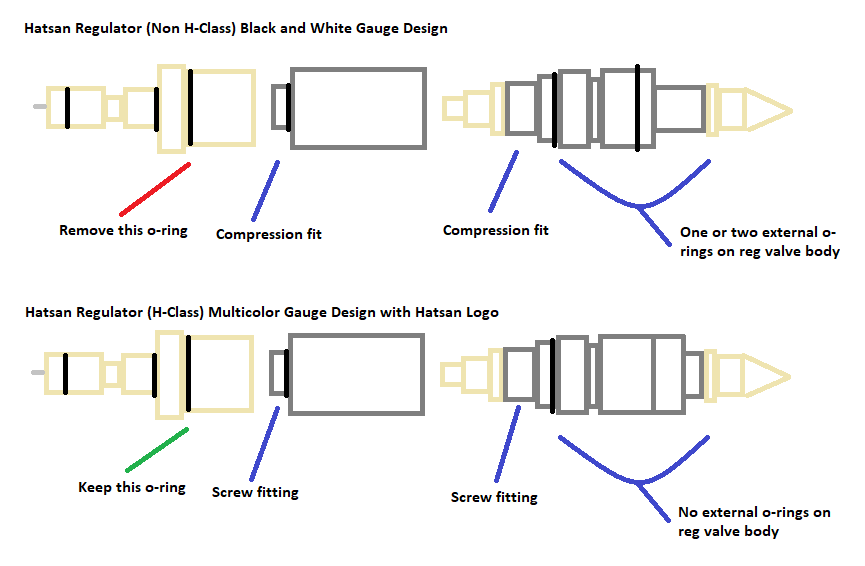

Like the air tubes, there is a non-H Regulator (simply called a Hatsan Regulator) and an H-Class Hatsan Regulator. The older design used a compression fit between each piece and had an external o-ring or two at the end of the regulator. Due to this external o-ring you HAD TO remove the main o-ring around the valve threads that secured the valve to the air tube. This is a terrible design because of the unreliability of the compression fittings and the external o-ring on the end of the regulator meant that all the space around and in front of this o-ring was dead space that took away from your fill capacity. The newer H-Class Regulator dealt with both of these problems as the external o-ring was no-more and all fittings used a screw design to ensure they mated properly. The terrible instructions mentioned the newer regulator but never said what to do with it. The main thing the instructions forgot was to say if you have an H-Class Regulator that main o-ring around the valve threads NEEDS TO STAY. This makes the newer H-Class valve and H-Class Regulator truly drop-in ready. Too bad the instructions were so poorly written.

Here is a diagram of the different regulators and what to do/not do with the o-rings:

OK... But is It Adjustable?

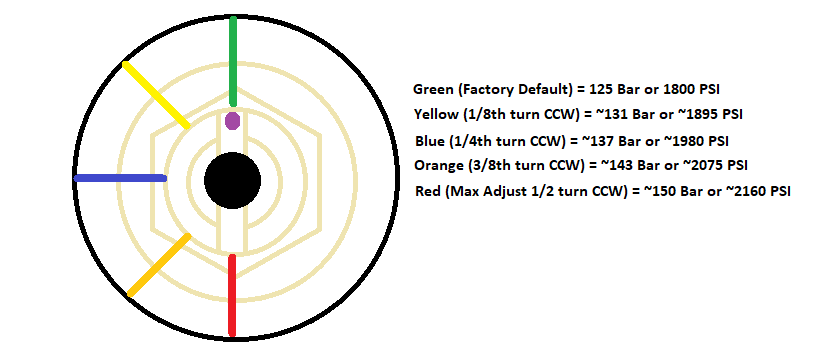

Yes the instructions give a very brief explanation of it's adjust-ability but never talk about it's capabilities. The regulator is made of two parts: the plenum (the cup looking thing that holds the air charge) and the regulator valve itself. For the regulator, one end looks like a little gold sponge and the other end looks like the worlds most complicated brass flathead screw. This is the side that you will adjust. "But it doesn't have any markings how will I ever know what its pressure is?" said the average air-gunner. Well you just have to test it out with a chronograph to see where your consistency drops off, but rest assured that as the instructions state the regulator SHOULD come from the factory set to around 125BAR or ~1800PSI and that's exactly where mine was at. To adjust it you turn it counter-clockwise (left) to increase regulator pressure and clockwise (right) to decrease it. What I did is calculate via the instructions that 1/2 a turn from stock should be about 25BAR of adjustment. So I took sharpies of different colors and marked 1/8 turns from start to a full half turn. Make sure to mark the right screw end so you don't confuse how far you've gone (the purple dot). This way you have several "known" points to reference when you test your rifle's velocity. I was using it in a .25 cal and noticed that each 1/8th of a turn produced about 5FPS faster shots at the detriment of 100PSI higher regulator pressure. So this thing works... but it is hella not efficient. You can expect anywhere from 5-15FPS change depending on caliber with each 1/8th of a turn. At a quarter turn I was at a reg pressure of about 137BAR or 1980PSI and achieved 800fps with JSB Exact King Heavy MKII 34gr pellets... but at a cost of only 12 regulated shots. Gross... so I dialed it back to stock pressure settings of 125BAR or 1800PSI and cranked down the hammer throw to produce 761FPS as if I switch to the normal Kings they should be around 880fps based on calculations. <-- This will be much better and yielded 18 regulated shots exactly, which is the amount my two included clips give me, so I'm happy with that.

Example of marking the top adjustment screw:

In Conclusion

Yes this thing works as I got 18 shots with a standard deviation of 3.50 and a spread of 12 across those 18 regulated shots. It seems to work best at 1900PSI or 131BAR which is 1/8th of a turn counter-clockwise from stock, as I got a standard deviation of 1.50 and a spread of 4... but my shot count did not cover my two clips so... wha-wuh. So it works, but is inefficient and it mostly stems from the fact that it seems to be designed for the .177 and .22 calibers as it is pushing it's limits by using it in the .25 caliber (needs bigger plenum). Also know that you NEED TO ADJUST THE HAMMER THROW to optimize the use of this regulator. It's not a drop-in-and-works-awesome-thingy as is with most other regulators. I had to adjust my hammer throw to ~8 turns out to achieve the speeds I did and to not have so much dwell as that would allow the valve to stay open long enough to defeat the purpose of the regulator. You will know this by the increasingly larger standard deviation. So if you're cheap like me and want to check out the Hatsan, know it's much better than most people make it out to be, but it's merely OK it gets the job done design at best.

I was using a hand pump while testing and since you have to drain the air every time you make a reg adjustment, I had to pump from 0-3000psi about 12 times.

Me after testing:

Hope you enjoyed this and it helps those that have a Hatsan regulator. Here are the bad Hatsan instructions for reference:

View attachment 1569727824_21399224205d902550c3f3f7.55824064_RegInstall2018.pdf

View attachment 1569727824_21399224205d902550c3f3f7.55824064_RegInstall2018.pdf

Where the Confusion Starts

First off Hatsan, like many companies, is constantly iterating over the same designs. What this means is that an AT44 bought in 2019 is different from an AT44 from 2018 and very different from one back in 2014. Many of these changes are minor improvements like pre-drilling holes in the stock to allow hammer throw adjustment without stock removal. Others are cost cutting changes that improve profits but can reduce reliability. Luckily the AT44 platform is very simple and mostly free from these cost-cutting changes or at least not impacted so much from them. The point is, the main change causing confusion is the change in valve design. There is a non-H class air tube and an H class air tube.

The Non-H class (classic) air tube looks like this:

The H class (newer) air tube looks like this:

With the changes to the air tube design there also came several iterations to the valve which is the most important. If you buy the wrong air tube and put it on the wrong gun you're going to have a bad time. This is the first concern. If you add a regulator to the mix it makes things even worse... so, the changes were so much so that they had to produce two different regulators to account for these design shifts.

Hatsan Regulator vs H-Class Hatsan Regulator vs The Install Instructions

Like the air tubes, there is a non-H Regulator (simply called a Hatsan Regulator) and an H-Class Hatsan Regulator. The older design used a compression fit between each piece and had an external o-ring or two at the end of the regulator. Due to this external o-ring you HAD TO remove the main o-ring around the valve threads that secured the valve to the air tube. This is a terrible design because of the unreliability of the compression fittings and the external o-ring on the end of the regulator meant that all the space around and in front of this o-ring was dead space that took away from your fill capacity. The newer H-Class Regulator dealt with both of these problems as the external o-ring was no-more and all fittings used a screw design to ensure they mated properly. The terrible instructions mentioned the newer regulator but never said what to do with it. The main thing the instructions forgot was to say if you have an H-Class Regulator that main o-ring around the valve threads NEEDS TO STAY. This makes the newer H-Class valve and H-Class Regulator truly drop-in ready. Too bad the instructions were so poorly written.

Here is a diagram of the different regulators and what to do/not do with the o-rings:

OK... But is It Adjustable?

Yes the instructions give a very brief explanation of it's adjust-ability but never talk about it's capabilities. The regulator is made of two parts: the plenum (the cup looking thing that holds the air charge) and the regulator valve itself. For the regulator, one end looks like a little gold sponge and the other end looks like the worlds most complicated brass flathead screw. This is the side that you will adjust. "But it doesn't have any markings how will I ever know what its pressure is?" said the average air-gunner. Well you just have to test it out with a chronograph to see where your consistency drops off, but rest assured that as the instructions state the regulator SHOULD come from the factory set to around 125BAR or ~1800PSI and that's exactly where mine was at. To adjust it you turn it counter-clockwise (left) to increase regulator pressure and clockwise (right) to decrease it. What I did is calculate via the instructions that 1/2 a turn from stock should be about 25BAR of adjustment. So I took sharpies of different colors and marked 1/8 turns from start to a full half turn. Make sure to mark the right screw end so you don't confuse how far you've gone (the purple dot). This way you have several "known" points to reference when you test your rifle's velocity. I was using it in a .25 cal and noticed that each 1/8th of a turn produced about 5FPS faster shots at the detriment of 100PSI higher regulator pressure. So this thing works... but it is hella not efficient. You can expect anywhere from 5-15FPS change depending on caliber with each 1/8th of a turn. At a quarter turn I was at a reg pressure of about 137BAR or 1980PSI and achieved 800fps with JSB Exact King Heavy MKII 34gr pellets... but at a cost of only 12 regulated shots. Gross... so I dialed it back to stock pressure settings of 125BAR or 1800PSI and cranked down the hammer throw to produce 761FPS as if I switch to the normal Kings they should be around 880fps based on calculations. <-- This will be much better and yielded 18 regulated shots exactly, which is the amount my two included clips give me, so I'm happy with that.

Example of marking the top adjustment screw:

In Conclusion

Yes this thing works as I got 18 shots with a standard deviation of 3.50 and a spread of 12 across those 18 regulated shots. It seems to work best at 1900PSI or 131BAR which is 1/8th of a turn counter-clockwise from stock, as I got a standard deviation of 1.50 and a spread of 4... but my shot count did not cover my two clips so... wha-wuh. So it works, but is inefficient and it mostly stems from the fact that it seems to be designed for the .177 and .22 calibers as it is pushing it's limits by using it in the .25 caliber (needs bigger plenum). Also know that you NEED TO ADJUST THE HAMMER THROW to optimize the use of this regulator. It's not a drop-in-and-works-awesome-thingy as is with most other regulators. I had to adjust my hammer throw to ~8 turns out to achieve the speeds I did and to not have so much dwell as that would allow the valve to stay open long enough to defeat the purpose of the regulator. You will know this by the increasingly larger standard deviation. So if you're cheap like me and want to check out the Hatsan, know it's much better than most people make it out to be, but it's merely OK it gets the job done design at best.

I was using a hand pump while testing and since you have to drain the air every time you make a reg adjustment, I had to pump from 0-3000psi about 12 times.

Me after testing:

Hope you enjoyed this and it helps those that have a Hatsan regulator. Here are the bad Hatsan instructions for reference: