(Again, credit for this idea to Motorhead)

This is the next step of this heavy .20 from .22 experiment....

Prior testing and general process described here....

https://www.airgunnation.com/topic/20-jsb-exact-jumbo-heavies/?referrer=1

https://www.airgunnation.com/topic/noe-22-19-6-grain-mold-sized-down-to-20/?referrer=1

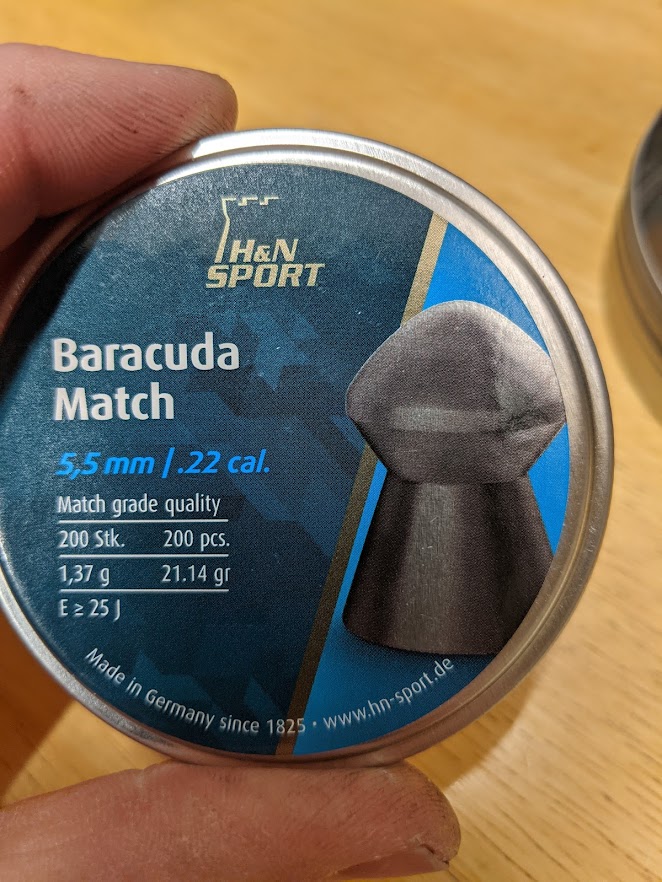

So, these....

Become these.....

I'm getting 0.201 for head size, 0.205 for the skirt, and 0.335 for oal. Weighed the post-sizing and they're coming out at 21.1-21.3grains.

The fastest I can get them without bumping to a heavier hammer spring is 745, for 26fpe. (Test gun is .20 Veteran Short).

Accuracy results to follow....

A couple of asides here:

This is the next step of this heavy .20 from .22 experiment....

Prior testing and general process described here....

https://www.airgunnation.com/topic/20-jsb-exact-jumbo-heavies/?referrer=1

https://www.airgunnation.com/topic/noe-22-19-6-grain-mold-sized-down-to-20/?referrer=1

So, these....

Become these.....

I'm getting 0.201 for head size, 0.205 for the skirt, and 0.335 for oal. Weighed the post-sizing and they're coming out at 21.1-21.3grains.

The fastest I can get them without bumping to a heavier hammer spring is 745, for 26fpe. (Test gun is .20 Veteran Short).

Accuracy results to follow....

A couple of asides here:

- It's been very interesting to see the "flow" properties of JSB lead vs cast lead vs H&N lead. They simply don't behave the same. The cast was 95%+ JSB and it didn't size as easy as the JSB 18.13s. One airgun friend suspects the casting process gives it more of a granular structure.

- I've been measuring ratios of overall length to the caliber size and finding some interesting ratios of the "best" (wind resistance/BC/long range accuracy/etc) performing pellets. I'll likely create a post on my thoughts and notes on that seemingly magic ratio in a separate post at some point in the future.

- The two large "driving bands" on the head and skirt are robbing me of some energy. JSB knows what they're doing in having minimal contact area on the head and skirt. The same hammer tension that throws a 15.89gr JSB factory .20 @ 910 will only push my 21.2grn H&N .20s at 630fps. I've got to max out the hammer tension for the 745fps cited above. The roughly 5grain difference definitely accounts for some of the loss in speed, but it seems to me there shouldn't be as large of a disparity in speeds. I'm chalking it up to friction from the large driving bands that result from the sizing process.