OldSpook,

I agree that 2 shots are not really enough for a sound measurement. It is like a 2 shot group. So, 10 is better than 2; but 2 may be better than none. At least to get some idea if there are significant trends. More shots equals more confidence, but at some point a test may become so onerous that people don't want to do it.

One shortcut one participant took, that was still fully meaningful was to skip the middle baffle bore size; and to compare on the largest and smallest. So deviations from full data sets can still be useful. Or at least worth more than having nothing.

You might think my standards are too low, but I am not paying or coercing people who print and test my moderator designs. They do it because they want to. If I am a pain to "work" with, they won't have any interest in trying again. So, I am grateful for what I get. If I act like an ingrate, volunteers will be put off.

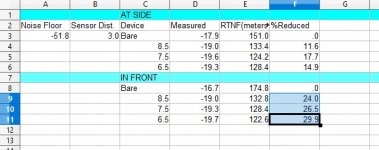

Mike was using a dB meter, rather than a cell phone app. Yes, all dB meters are not equal. Yes, the instrument needs to be used correctly. Set to "fast" or instantaneous, rather than averaging over so many seconds. The frequency range needs to be optimized for human hearing, if the meter supports that.

Now, I could spec the tools and methods, and insist on calibration, but at some point people just wont participate. So, I take what I can get, and if I think readings are not useful (pegging the meter is easily identified), I will first try to guide that person to eliminate that problem. Then I would pay more attention to the readings I have more confidence in. And ignore any readings I think are corrupt or obviously not real. What I won't do, is insult people for producing bad data.

**** Moderated content removed ***:

Off Topic

Inflammatory

Trolling

I agree that 2 shots are not really enough for a sound measurement. It is like a 2 shot group. So, 10 is better than 2; but 2 may be better than none. At least to get some idea if there are significant trends. More shots equals more confidence, but at some point a test may become so onerous that people don't want to do it.

One shortcut one participant took, that was still fully meaningful was to skip the middle baffle bore size; and to compare on the largest and smallest. So deviations from full data sets can still be useful. Or at least worth more than having nothing.

You might think my standards are too low, but I am not paying or coercing people who print and test my moderator designs. They do it because they want to. If I am a pain to "work" with, they won't have any interest in trying again. So, I am grateful for what I get. If I act like an ingrate, volunteers will be put off.

Mike was using a dB meter, rather than a cell phone app. Yes, all dB meters are not equal. Yes, the instrument needs to be used correctly. Set to "fast" or instantaneous, rather than averaging over so many seconds. The frequency range needs to be optimized for human hearing, if the meter supports that.

Now, I could spec the tools and methods, and insist on calibration, but at some point people just wont participate. So, I take what I can get, and if I think readings are not useful (pegging the meter is easily identified), I will first try to guide that person to eliminate that problem. Then I would pay more attention to the readings I have more confidence in. And ignore any readings I think are corrupt or obviously not real. What I won't do, is insult people for producing bad data.

**** Moderated content removed ***:

Off Topic

Inflammatory

Trolling

Last edited by a moderator:

Upvote 0