This morning I recovered the bolts that I couldn’t see where they hit and passed through my backstop when shooting yesterday evening during sunset. The one I previously thought had missed the backstop completely was the first that I recovered. Apparently it landed just below the one that the fletching tore off of. The wood at the bottom of the plywood backstop is softer from being in contact with the moisture on the ground so the bolt just blew through it without making a distinct shaped hole. I didn’t realize the lower hole was from a bolt. All things considered, the accuracy is there. I did (or didn’t do) something to cause these shots to hit low and left of the target. I probably pulled the shots while shooting kneeling from behind my Primos Trigger Stick bipod and taking quick shots. Both shots are within 2 ¼”- 2 ½”. For a broadhead I believe that’s decent at 49-50 yards away.

The bolt spent the night lodged in the wet soil. I have to clean it up, but the shaft and nock appear to be intact and the nock o-ring stayed put. The vanes are still tattered from my initial test shooting with the Donny FL shroud endcap adapter affixed. I’ll replace them after I attempt to practice re-fletching the bolt that’s already in need of repair. Below is a photo after I pulled it out of the dirt and grass.

I bent a blade and the tip was loose. Easy enough to screw back into the tip of the arrowhead. I need to find out if the blades can be replaced.

Anyone think that a slightly bent blade makes it a bad broadhead for target practice? Does a bent blade significantly affect flight? I wish I took a photo of where it landed. I was happy to find it and

happy to know that no shots went over or around my backstop.

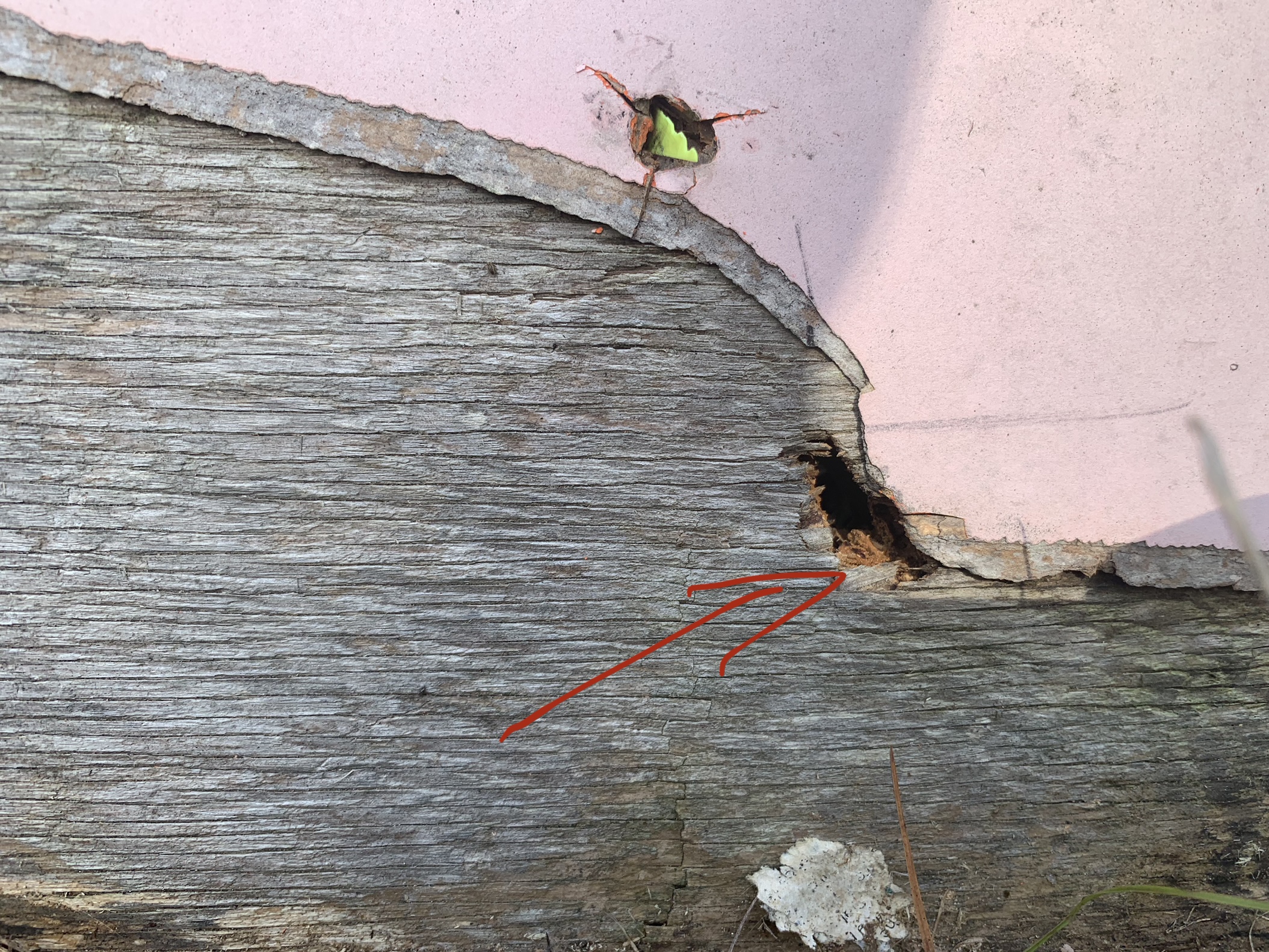

Below you can see the other broadhead that blasted through the solid part of the wood and left a piece of a vane protruding from the hole in the plywood. Found it in dirt and grass behind the backstop. The shaft appears to be intact. I’ll inspect it closer when I clean it up. Below is how I found it . The tip of this broadhead is still sharp to the touch on the tip of my finger.

These broadheads are pretty robust. I bent a blade on this one. I think they are clipping the wire on the other side of the plywood after passing through. I have to figure out how to re-fletch this one. The vanes are shot and one ripped completely off of the shaft when passing through the plywood.

The above blade on the left got nicked, probably on the wire. I’m surprised at how these bolts are holding up. If they can withstand passing through ¾” plywood I think they’ll be good to go through deer bone. I’m confident they destroy pig bones. I’m not familiar with coyote bone density, but I think these broadheads/bolts at the velocities I’ve recorded would be absolute hell on a yote.

Recovering these two bolts and broadheads is like me finding $60 I’d misplaced. Works for me, but even more so I can evaluate their performance after undergoing the stress of impact and such. I imagine I’ll see a somewhat similar result after hitting animal bone. Maybe some experienced archers can chime in with more definite info here. I’m speculating.

And I was mistaken. This plywood looks to be about

3/4” thick, not 1/4”.