After watching the FedEx guy video chat for 25 minutes while parked in the right lane of the busiest street in a 250,000 person city, it has arrived.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crosman 3622 - On to Optic 👍

- Thread starter Momar2

- Start date

Things of note right off the bat in no particular order.

The barrel is not the same as the 362. It has a very smooth finish, not like the machined finish of the 362, 2240 etc. Much more like the Lothar barrels.

It has a hammer spring adjuster. It will have to be removed from the stock to adjust. I will be modifying the stock so I don't have to do that.

The trigger guard is plastic as opposed to the aluminum guard on the 362.

The manual says 3677 and 3622. There will be a .177.

The box says 3622 "Syn" for synthetic. This leads me to believe there will be a wood stock version.

It's super light. Can't be 4lbs. I don't have a scale that accurately measures under 5lbs, anymore

The barrel bands are 'locked' into the stock and the barrel is perfectly centered.

The bolt probe is longer and thinner than previous models.

The tube diameter matches the 13xx series, not the 2240 series. The valve will obviously be closer to the pumper valve. Interesting.

Pending accuracy testing, I love it. It appears to be worth every penny and then some.

It does have a 5 year warranty.

Well done, Crosman.

The barrel is not the same as the 362. It has a very smooth finish, not like the machined finish of the 362, 2240 etc. Much more like the Lothar barrels.

It has a hammer spring adjuster. It will have to be removed from the stock to adjust. I will be modifying the stock so I don't have to do that.

The trigger guard is plastic as opposed to the aluminum guard on the 362.

The manual says 3677 and 3622. There will be a .177.

The box says 3622 "Syn" for synthetic. This leads me to believe there will be a wood stock version.

It's super light. Can't be 4lbs. I don't have a scale that accurately measures under 5lbs, anymore

The barrel bands are 'locked' into the stock and the barrel is perfectly centered.

The bolt probe is longer and thinner than previous models.

The tube diameter matches the 13xx series, not the 2240 series. The valve will obviously be closer to the pumper valve. Interesting.

Pending accuracy testing, I love it. It appears to be worth every penny and then some.

It does have a 5 year warranty.

Well done, Crosman.

Last edited:

Upvote 0

20 shot string - 2000psi fill - CPHP

697

697

698

709

705

712

712

712

712

714

712

707

711

708

701

699

692

689

678

666

697

697

698

709

705

712

712

712

712

714

712

707

711

708

701

699

692

689

678

666

Last edited:

Upvote 0

It doesn't. Didn't expect it to as it's exactly like a 1322 from the valve rearward. It's nothing like the POS Chinese Icon that has a ridiculously heavy hammer and a weak hammer spring which is the reason that design bump fires when decocked.have you tested for bump fire.......

I don't even think I'm going to do anything but polish the hammer for now. I would rather have a 24" barrel for a few reasons but I'll shoot it the way it is for a while.

Upvote 0

Interesting that they went with the smaller diameter reservoir tube. A bigger tube would seem like an easy way to cheaply get a much higher shot count.

Upvote 0

The rear half of the stock is exactly like the 362 which fits the pumper tube and the pumper valve is already sealed and set up for pressure in the tube. All to make the gun a budget PCP by saving on having to make a whole new mold for a stock. Brand new tooling is expensive. It makes more sense when you hold it. They went for lower cost vs. higher shot count. Hence budget PCP. If they used a 22xx diameter tube it would have been a lot more expensive because it would have to have a whole different stock. Also makes for a super light gun. I'm glad they did it this way. I used a compressor to fill but the smaller tube does offer the advantage of less pumping with a hand pump which is probably good for the average consumer.Interesting that they went with the smaller diameter reservoir tube. A bigger tube would seem like an easy way to cheaply get a much higher shot count.

Last edited:

Upvote 0

Smaller tube does not offer less pumping for handpumpers,The rear half of the stock is exactly like the 362 which fits the pumper tube and the pumper valve is already sealed and set up for pressure in the tube. All to make the gun a budget PCP by saving on having to make a whole new mold for a stock. Brand new tooling is expensive. It makes more sense when you hold it. They went for lower cost vs. higher shot count. Hence budget PCP. If they used a 22xx diameter tube it would have been a lot more expensive because it would have to have a whole different stock. Also makes for a super light gun. I'm glad they did it this way. I used a compressor to fill but the smaller tube does offer the advantage of less pumping with a hand pump which is probably good for the average consumer.

pumping is directly related to power output and how many shots you take between pumping sessions, air vessel size is irrelevant.

Upvote 0

If you want to take, for example, a set amount of 100 shots then of course it's going to take the same amount of pumps to achieve any overall shot count regardless of vessel size.Smaller tube does not offer less pumping for handpumpers,

pumping is directly related to power output and how many shots you take between pumping sessions, air vessel size is irrelevant.

It does equal less pumps per fill so it's not irrelevant. If the vessel is 135cc it's going to take less pumps to take it from 1000psi to 2000psi than it would take to fill a 255cc vessel from 1000psi to 2000psi. So in fact it will take less pumps per fill. There are bound to be more people who are able to pump 30 times per fill than 100 times per fill. It's not rocket science. I understand what you're saying and if you can't understand what I'm saying I can't help you.

Last edited:

Upvote 0

Thanks for posting this - is there a way you could post a detailed pic of the fill set up? Just curious.

The smaller od tube explains a lot, so the valve is anchored the same way as a pumper? I obviously have a big hole in my Crosman knowledge when it comes to their pumpers.

The smaller od tube explains a lot, so the valve is anchored the same way as a pumper? I obviously have a big hole in my Crosman knowledge when it comes to their pumpers.

Upvote 0

Haven't taken it out of the stock yet I will report on the valve anchor setup later. I assume it is the same as a 1322.Thanks for posting this - is there a way you could post a detailed pic of the fill set up? Just curious.

The smaller od tube explains a lot, so the valve is anchored the same way as a pumper? I obviously have a big hole in my Crosman knowledge when it comes to their pumpers.

Pics of the foster. My QD barely squeezes by the front sight. I don't like that they coated it black, it will definitely look beat up in a hurry and the coating makes it a little tough to get the coupling to close. As you can see it's a bit of an interference fit with the sight. One of the factors for wanting a 24" barrel. The sight could be sanded some to create more clearance.

Upvote 0

24 shot string - 2000psi - 21 grain HN Slug HP

571

571

571

573

577

579

577

583

581

585

584

584

585

585

583

585

584

584

584

581

577

575

568

563

571

571

571

573

577

579

577

583

581

585

584

584

585

585

583

585

584

584

584

581

577

575

568

563

Upvote 0

Thank you for the quick reply. Is it my eyes lying to me or was the front sight hooded in your first pic?

Upvote 0

It was. I took it off. Does nothing for me.Thank you for the quick reply. Is it my eyes lying to me or was the front sight hooded in your first pic?

Upvote 0

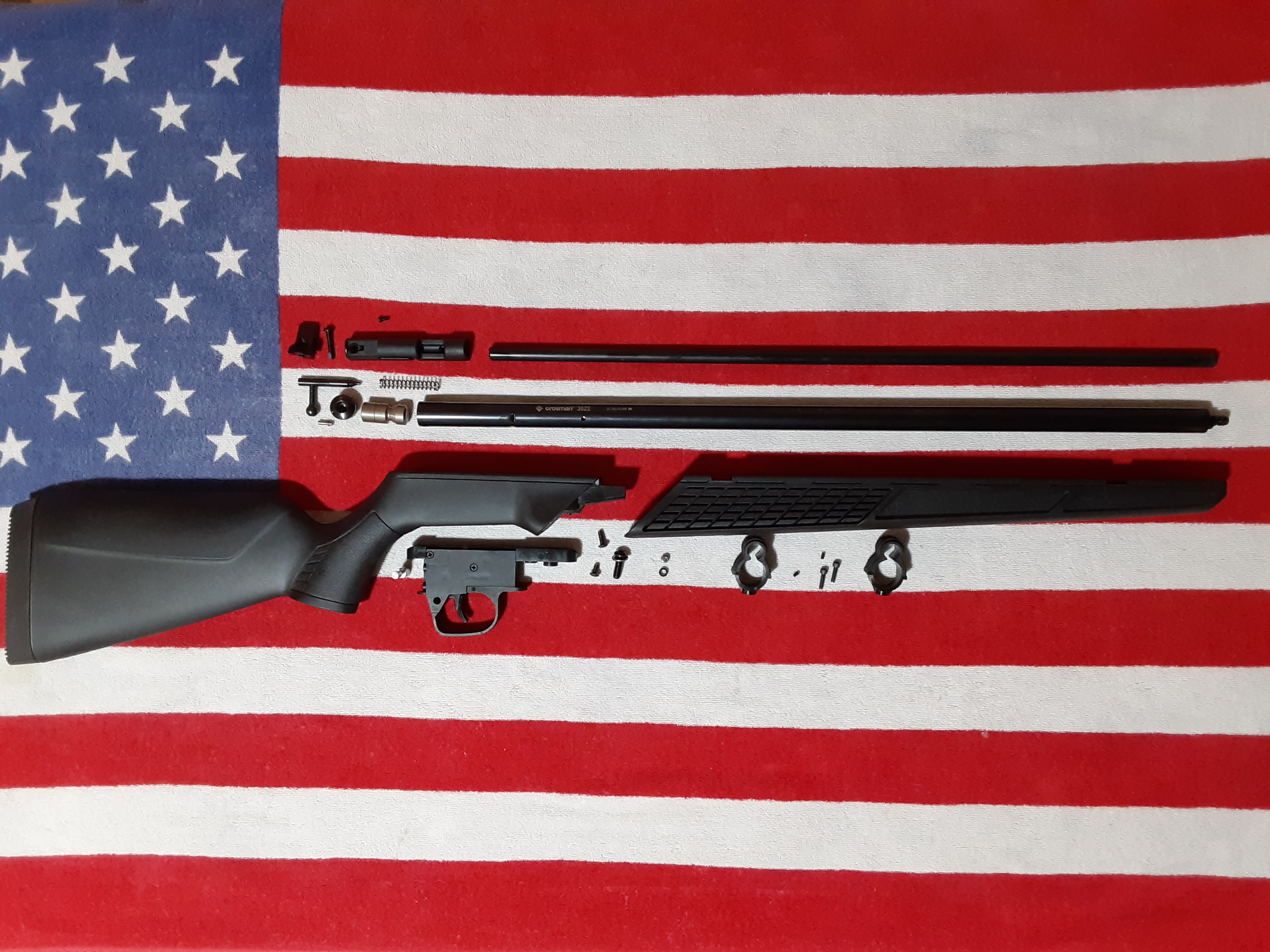

Per usual it's in pieces less than 24hrs after getting here.

Yes it has the same valve, anchored the same way as a 1322 via the tube being punched.

The transfer port is the standard size. I'm going to swap it for a larger one just because I have one. Eventually I will port the valve but I'm in no hurry to do that yet.

The hammer is a little different than what I'm familiar with in that it has a groove in it and the spring hole is deeper. I think this is to offset the depth the spring adjuster gives up and keeps the spring from deflecting when it is turned in. Seems a little self-canceling and I would personally rather just tune with a fixed cap and swapping springs. The trigger group screw and the sight screw that retain the cap, drag on the adjuster/ lock it in place so adjusting is going to be a hassle anyway. Kind of seems like an afterthought to me. I'll probably swap for a regular cap because I have one here already and just tune with shim or spring swaps.

The barrel bands are not snug on the barrel and when the set screws are tightened it flexes the barrel down. I'll be adding some 2260 barrel trim to maintain a perfect gap between the barrel and tube from breech to muzzle. I don't like my barrels to be warped when installed.

I will polish the hammer for smooth cocking. Pretty standard on the platform.

I will replace the trigger return and main springs with lighter ones. The trigger is way too heavy as per usual on this group. It uses hex screws front and rear to attach to the tube intead of the funky square/slot rear screw that nobody likes. The sear will be deburred and polished.

Nothing I do today will cost anything but time because I have the parts. The rear cap doesn't have to be swapped and many will choose not to.

I think I will avoid spending $ on the gun for now as it is definitely going to have limitations that money won't exceed reasonably. Even adding a breech and 2 piece bolt will push it over the "should've bought something else" budget imo.

As of right now it makes 16fpe on the nose as advertised. I'm going to shoot for 20fpe with no $ spent and if I achieve that it will be well worth it and a success.

Yes it has the same valve, anchored the same way as a 1322 via the tube being punched.

The transfer port is the standard size. I'm going to swap it for a larger one just because I have one. Eventually I will port the valve but I'm in no hurry to do that yet.

The hammer is a little different than what I'm familiar with in that it has a groove in it and the spring hole is deeper. I think this is to offset the depth the spring adjuster gives up and keeps the spring from deflecting when it is turned in. Seems a little self-canceling and I would personally rather just tune with a fixed cap and swapping springs. The trigger group screw and the sight screw that retain the cap, drag on the adjuster/ lock it in place so adjusting is going to be a hassle anyway. Kind of seems like an afterthought to me. I'll probably swap for a regular cap because I have one here already and just tune with shim or spring swaps.

The barrel bands are not snug on the barrel and when the set screws are tightened it flexes the barrel down. I'll be adding some 2260 barrel trim to maintain a perfect gap between the barrel and tube from breech to muzzle. I don't like my barrels to be warped when installed.

I will polish the hammer for smooth cocking. Pretty standard on the platform.

I will replace the trigger return and main springs with lighter ones. The trigger is way too heavy as per usual on this group. It uses hex screws front and rear to attach to the tube intead of the funky square/slot rear screw that nobody likes. The sear will be deburred and polished.

Nothing I do today will cost anything but time because I have the parts. The rear cap doesn't have to be swapped and many will choose not to.

I think I will avoid spending $ on the gun for now as it is definitely going to have limitations that money won't exceed reasonably. Even adding a breech and 2 piece bolt will push it over the "should've bought something else" budget imo.

As of right now it makes 16fpe on the nose as advertised. I'm going to shoot for 20fpe with no $ spent and if I achieve that it will be well worth it and a success.

Last edited:

Upvote 0

Lightened trigger. Sear parts polished. Larger transfer port installed. Hammer polished. Non adjustable cap with nitrile spring shim installed. Barrel trim shims installed on each side of each barrel band.

Reassembled and ready for testing. Trigger is night and day better. Updated shot strings to follow.

Reassembled and ready for testing. Trigger is night and day better. Updated shot strings to follow.

Upvote 0

Well, that was easy.

First setting left the HS a tad lighter than it was factory and produced a really nice shot string.

24 shots - 2000psi - CPHP

674

681

690

692

700

697

701

705

708

707

709

706

707

710

707

702

707

701

689

692

690

684

677

-------------------

Slipped it out of the stock and added some preload. Things got interesting.

10 shots - 2000psi - CPHP

789 - 19.77 FPE

787

782

780

781

774

769

762

756

750

----------------

14 shots - 2000psi - 21g HN Slug HP (.218)

650

649

651

651

653

654 - 19.95 FPE - Mission Accomplished

652

654

653

651

650

648

644

633

--------------

I'd say this is a pretty good indication of the limitations of this gun. It can easily be tuned to get the factory claimed maximum energy for 20 shots. It can easily be tuned to reach nearly 20fpe for a dozen shots. That's pretty awesome for a gun that takes less than one minute to top off on my tiny Vevor compressor.

The shot strings in the sweet spot are extremely flat. It's more efficient with slugs at high power.

It would easily exceed 20fpe at these settings with a 24" barrel and possibly reach 25fpe with valve work, but it would not get many shots.

Noone is going to expect to get 30-40 shots per fill from this tiny tube, but if you detune it to get 12fpe it will surely do it.

I'm going to leave it just like it is for now. It does everything I wanted it to do and more. If I want more shots per fill for bench shooting I will tether it. I didn't put one extra dime into this gun to get these results. I am unequivocally impressed.

Stay tuned for accuracy testing. It might be a few days.

First setting left the HS a tad lighter than it was factory and produced a really nice shot string.

24 shots - 2000psi - CPHP

674

681

690

692

700

697

701

705

708

707

709

706

707

710

707

702

707

701

689

692

690

684

677

-------------------

Slipped it out of the stock and added some preload. Things got interesting.

10 shots - 2000psi - CPHP

789 - 19.77 FPE

787

782

780

781

774

769

762

756

750

----------------

14 shots - 2000psi - 21g HN Slug HP (.218)

650

649

651

651

653

654 - 19.95 FPE - Mission Accomplished

652

654

653

651

650

648

644

633

--------------

I'd say this is a pretty good indication of the limitations of this gun. It can easily be tuned to get the factory claimed maximum energy for 20 shots. It can easily be tuned to reach nearly 20fpe for a dozen shots. That's pretty awesome for a gun that takes less than one minute to top off on my tiny Vevor compressor.

The shot strings in the sweet spot are extremely flat. It's more efficient with slugs at high power.

It would easily exceed 20fpe at these settings with a 24" barrel and possibly reach 25fpe with valve work, but it would not get many shots.

Noone is going to expect to get 30-40 shots per fill from this tiny tube, but if you detune it to get 12fpe it will surely do it.

I'm going to leave it just like it is for now. It does everything I wanted it to do and more. If I want more shots per fill for bench shooting I will tether it. I didn't put one extra dime into this gun to get these results. I am unequivocally impressed.

Stay tuned for accuracy testing. It might be a few days.

Upvote 0

Your target was 20 FPE, and you only achived 19.95 FPE!

Dont stop there!

Your so close, its not funny!

Great write up, and great step by step explaination.

Very impressive for a inexpensive air gun.

Looking forward to your accuracy results!

Dont stop there!

Your so close, its not funny!

Great write up, and great step by step explaination.

Very impressive for a inexpensive air gun.

Looking forward to your accuracy results!

Upvote 0

Ask, and ye shall receive.Your target was 20 FPE, and you only achived 19.95 FPE!

Dont stop there!

10 shots - 2000psi - 18.13g HN Baracuda (5.52)

702

702

702

704

706 - 20.07 fpe -

706

705

702

699

695

I could tell from the comparison of velocity and efficiency data relative to head size and weight that my ringer pellet would deliver the knockout punch.

A stronger, shorter spring would exceed these results and possibly with better efficiency. I may have to invest the 49¢.

Upvote 0