You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

97cf carbon fiber fill tank condemned for a couple cracks in the thread

- Thread starter Airtillery

- Start date

I dont get it. Why do u think these carbon fiber tank blowing up is a joke and doesn't happen? Just cause it didn't happen to you doesnt mean it won't happen to anyone else. Go watch Joe brancato YouTube video on these carbon fiber tanks. They aren't a joke when then go kaboom. 4500 psi isn't something to laugh it.Blow up?Now that’s funny! I don’t care who you are.

.

Upvote 0

If you read the comments on that video you will find that they intentionally filled that tank to destruction. IIRC it was 10-12K psi. The US Navy says they have NEVER had a tank explode. They submitted that tanks should be retested and given a 30yr lifespan after the 15 year lifespan expires.I dont get it. Why do u think these carbon fiber tank blowing up is a joke and doesn't happen? Just cause it didn't happen to you doesnt mean it won't happen to anyone else. Go watch Joe brancato YouTube video on these carbon fiber tanks. They aren't a joke when then go kaboom. 4500 psi isn't something to laugh it.

View attachment 304937

Upvote 0

No Navy tanks. No Fireman tanks. No SCBA tanks. NONE have blown in the past 30+ years. That is why I’m laughing at the Blow Up comment. They just don’t fail that way while in use. Think about it. Firemen take these into burning buildings. And no failures. But if you can link to a report of this happening I’ll retract my comments.

They are made to withstand well beyond the pressure they hold,” Russ said. “They won't rupture until the internal pressure approaches about 20,000 psi. They are very safe.”

They are made to withstand well beyond the pressure they hold,” Russ said. “They won't rupture until the internal pressure approaches about 20,000 psi. They are very safe.”

Last edited:

Upvote 0

I took it as poking fun at the language "blow up" rather than saying rupture or explode. If Joe B's tank dun blowed up we better be careful.I dont get it. Why do u think these carbon fiber tank blowing up is a joke and doesn't happen? Just cause it didn't happen to you doesnt mean it won't happen to anyone else. Go watch Joe brancato YouTube video on these carbon fiber tanks. They aren't a joke when then go kaboom. 4500 psi isn't something to laugh it.

Upvote 0

I wish falling back on the warranty were as simple as you portray. The tank vendor, as I was in part expecting, does not believe there could be a crack in the threads and is wanting proof. If it is proven to have a crack, the vendor indicates I will be "taken care of". However, I now have to either ship the tank back to vendor (at my expense) to be inspected, or vendor will ship it off to the manufacturer to assess. Apparently there are only a couple HPA tank manufacturers in the U.S. Or I can pay for yet another $35 VI from a different inspector and see what occurs.If its under warranty get it return. If its out of warranty, trash it. Your life isn't worth saving a few hundred buck. These tanks are fill to 4500 psi. That is like a bomb going off when sht hits the fan. And you do not want to be near it when it goes off. If a professional inspected it and said its unsafe, I wouldn't use it.

While I fully concur that no one's life if worth $800+, from what I've been reading, even professionals make a misdiagnosis or false positive (or even negatives). As such, for now I'll deem the tank as unusable, pending a second opinion. But even then, if the 2nd VI inspector determines the tank as being safe, in some ways it won't completely instill my full confidence in all this. Of course, to eliminate any bias, I will not inform the 2nd VI inspector of having this previously inspected, until "after" the 2nd inspection, should I go this route. Being very new to air propelled devices and equipment, I do not have years of experience in all this. And because of the potentiality of a serious event, I'm going to err on the side of caution, at least at this juncture until I garner a much greater understanding of this issue and have greater level of confidence in the existing inspection standards and process. The more I read about all this, there seems to be a mixed review of the inspection standards, cooperation between different shops accepting another's annual VI inspection sticker, VI inspectors certifications and competence levels, and at best there appears to be some inconsistencies in it this whole VI process. There are not many places to get ones tank filled, so with these limited options, I'm at the mercy of a particular shops rules.

Upvote 0

That is in part what the tank vendor I bought the tank from has opined, but as I conveyed to "Airmanator", the warranty by the vendor is not so clear cut and dry and unfortunately not with an additional expense out of my pocket, which is a whole different battle.That doesn't make sense. Those 97cuft tanks are built like tanks. Somethings not adding up.

Contact the seller, as "they" move a lot of tanks should have some knowledge on this issue and offer at least a ship back to inspect the tank.

They also come with warranty when purchased new, and should be covered considering you also purchased the netting/bumpers for it to add protection.

In regards to the place that brought up the visual... Is this the same place that filled your tank with oxygen and/or couldn't fill passed 3k psi?

In regards to your last question: yes this was the same shop and as I previously updated, the "oxygen" issue was resolved and the last time I had it filled at this very shop, there were able to get it to about 4.1k, with a little extra effort. So I was shocked that all of a sudden they sprung this VI requirement on me.

Upvote 0

Thanks for the link and tip!Since I have never heard of this inspection I looked it up:

https://cylindertrainingservices.com/visual-inspection-stickers/

Once this is resolved I would ask to see their training certificate.

Upvote 0

could be ? they do not want to stress their equipment filling to 4500 so fail inspection for a questionable crack . with the past history i might not want them to fill my tank anyway .That is in part what the tank vendor I bought the tank from has opined, but as I conveyed to "Airmanator", the warranty by the vendor is not so clear cut and dry and unfortunately not with an additional expense out of my pocket, which is a whole different battle.

In regards to your last question: yes this was the same shop and as I previously updated, the "oxygen" issue was resolved and the last time I had it filled at this very shop, there were able to get it to about 4.1k, with a little extra effort. So I was shocked that all of a sudden they sprung this VI requirement on me.

Upvote 0

When it comes to any legal requirements or DOT & ISO regulatory bodies that establish HPA tank standards, I could not speak on this or be able to make a firm statement that annual inspections are "not" required by law. May I ask your source of this seemingly definitive statement? I not able to confirm this either way.Seems sketchy at best. Annual inspections are not required by law.

And for the post a few above that says the failure mode is “explosion”, I’d love to see just one incident of that in the past 30 years where a DOT tank “exploded”. It just doesn’t happen that way…

Thread inspection criteria.

- Reject all cylinders with corroded or damaged threads.

- Reject all cylinders that show evidence of cracking in more than one continuous full thread. Contact the Manufacture with this information and findings. If you are unsure whether you are detecting a harmless tool-stop mark or a crack, contact the Manufacturer for guidance before rejecting a cylinder.

- Reject all cylinders with O-ring gland cracks, face cracks or other damage that may prevent an effective and safe seal.

- Return to service all cylinders with acceptable glands, faces and threads (including those with harmless tool-stop marks)

In regards adverse events with HPA tanks, I'm still looking into this. But while there does appear to a few incidents, whenever there is one, it invariable has either a tragic ending or with very significant injury and property damage.

Thanks for pasting in the thread inspection criteria. I did read this. But since such inspections are conducted with an imperfect human that is prone to error based on ones experience, work tolerance and eyesight, it appears per a report by "Luxfer: (http://www.psicylinders.com/inspect...scuba-aluminum-cylinders-made-from-6351-alloy)", that half of all tanks assessed with a thread crack, were "not" cracks at all. This does not instill a whole lot of confidence in those that perform VI!!! And if the the individual had followed the above guideline you posted above, I would not be in possession of my tank. Unfortunately and additionally, the VI inspector that dinged my tank, appeared to skip this step and claimed he was supposed to condemn and destroy the tank. And as I stated in my opening post, I was able to convince the inspector to not take this drastic measure by giving my word as one Veteran to another that I will not fill this tank, but will pursue a replacement with the vendor I bought it from.

Upvote 0

Anything is possible, but even if that were the case, I still have to resolve this in the safest way possible, balanced with what is prudent and counting the cost involved.Sounds like they don't want to fill your tank anymore, and are trying to find a reason why.

Upvote 0

I thoroughly inspected inside my used, out of date Scott SCBA 60 min tank with a Teslong bore light before I filled it for the first time. It was an easy job. I can see how an inspector could misinterpret machining / tapping marks for cracks. If they gave you back your tank, perhaps you could buy a Teslong and take a look for yourself. If you can confirm that they are not stress cracks, consider filling it yourself. Of all the places on a tank, the neck threads seem to me to be the strongest and least likely place for cracks to form. My guess is inspector error.

Last edited:

Upvote 0

I tried doing this and unfortunately it was not easy to capture an image with my cell phone trying to peer through a small microscope with a bright light shining on the alleged cracks, that ended up being washed out by the light, even though we were able to see the lines that appeared to be cracks, or potentially "tap stops" with our eyes. Attached is the image I was able to get, but really doesn't show anything for the aforementioned reasons. The line were were seeing is in the 2nd to the last thread valley from left to right. You will see some shadow like artifacts from the bright light reflecting off the thread metal and right above that is were the supposed crack is at.Can you take a picture of the cracks yourself? Thread crack seems unlikely as the pressure from the valve is spread over all the engaged threads.

As far as your hypothesis on the unlikeliness of a crack something I can not speak on for I have not experience on this nor any expertise on it. May I ask, is your comment based on a presumption or from some form of experience? Thanks...

Upvote 0

I tried doing this and unfortunately it was not easy to capture an image with my cell phone trying to peer through a small microscope with a bright light shining on the alleged cracks, that ended up being washed out by the light, even though we were able to see the lines that appeared to be cracks, or potentially "tap stops" with our eyes. Attached is the image I was able to get, but really doesn't show anything for the aforementioned reasons. The line were were seeing is in the 2nd to the last thread valley from left to right. You will see some shadow like artifacts from the bright light reflecting off the thread metal and right above that is were the supposed crack is at.

As far as your hypothesis on the unlikeliness of a crack something I can not speak on for I have not experience on this nor any expertise on it. May I ask, is your comment based on a presumption or from some form of experience? Thanks...

View attachment 305272

IF this is a made in US scba tank then it’s very unlikely to have stress crack by the threads, the threaded section is quite long and evenly distributes the force. From your picture it looks like a scratch/machine mark more than stress/hairline crack.

There still isn’t a known case of certified made in US scba tank or valve fail catastrophically under normal working pressure. I have 3 tanks and zero issues, they all get DOT hydro tested and all pass with flying colors.

Upvote 0

Been following this, just had a thought — how about a partial fill, 500 psi or so then a dunk in water.

I would think a crack would leak...

I would think a crack would leak...

Upvote 0

That looks like a tool mark to me.

It just doesn’t make sense that there would be a crack located in the valley of one thread. Especially on a specialty high pressure tank designed to work under harsh conditions.

I think this is much ado about nothing.

Were it me, I’d fill it up and never give it a second thought.

It just doesn’t make sense that there would be a crack located in the valley of one thread. Especially on a specialty high pressure tank designed to work under harsh conditions.

I think this is much ado about nothing.

Were it me, I’d fill it up and never give it a second thought.

Upvote 0

D

Deleted member 15252

Guest

I would approach the dive shop inspector with my doubts and ask how they determine cracks from machine marks. This test sounds too subjective to be of value. If anywhere close to 50 per cent are misdiagnosed what's the point? I would at least ask the shop the questions I had while I was looking for another dive shop.

Upvote 0

I see nothing that even looks a little like a crack. Did it ever look like an actual crack when you were moving it around?

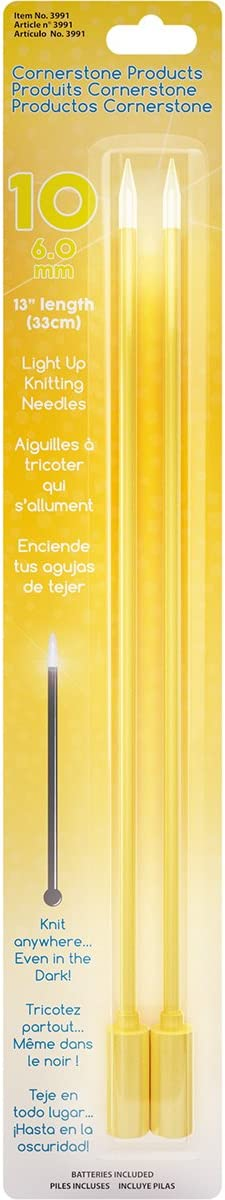

To get good photos through a scope you need to have a separate light source so that the light isn't directly shining on the area you want to capture. An easy and inexpensive way to do that for your use would be an illuminated knitting needle. You can position the lighted end of the needle just right to give a non glare image. Turn the light on the scope off. I use the knitting needle when inspecting rifle bores as well. If you get one that is fairly long you can insert it from either end to fully light up the entire bore. Sometimes a piece of tracing paper taped on the tip of the needle to act as diffuser helps reduce glare even more.

To get good photos through a scope you need to have a separate light source so that the light isn't directly shining on the area you want to capture. An easy and inexpensive way to do that for your use would be an illuminated knitting needle. You can position the lighted end of the needle just right to give a non glare image. Turn the light on the scope off. I use the knitting needle when inspecting rifle bores as well. If you get one that is fairly long you can insert it from either end to fully light up the entire bore. Sometimes a piece of tracing paper taped on the tip of the needle to act as diffuser helps reduce glare even more.

Upvote 0

Aluminum doesn't like Sharp edges. If it were to crack it would be at the base of the thread or the top not in the middle of the threads valley. Do need a better picture of supposed crack.

Upvote 0