You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Air Arms AA Prosport owners…

- Thread starter bustachip

- Start date

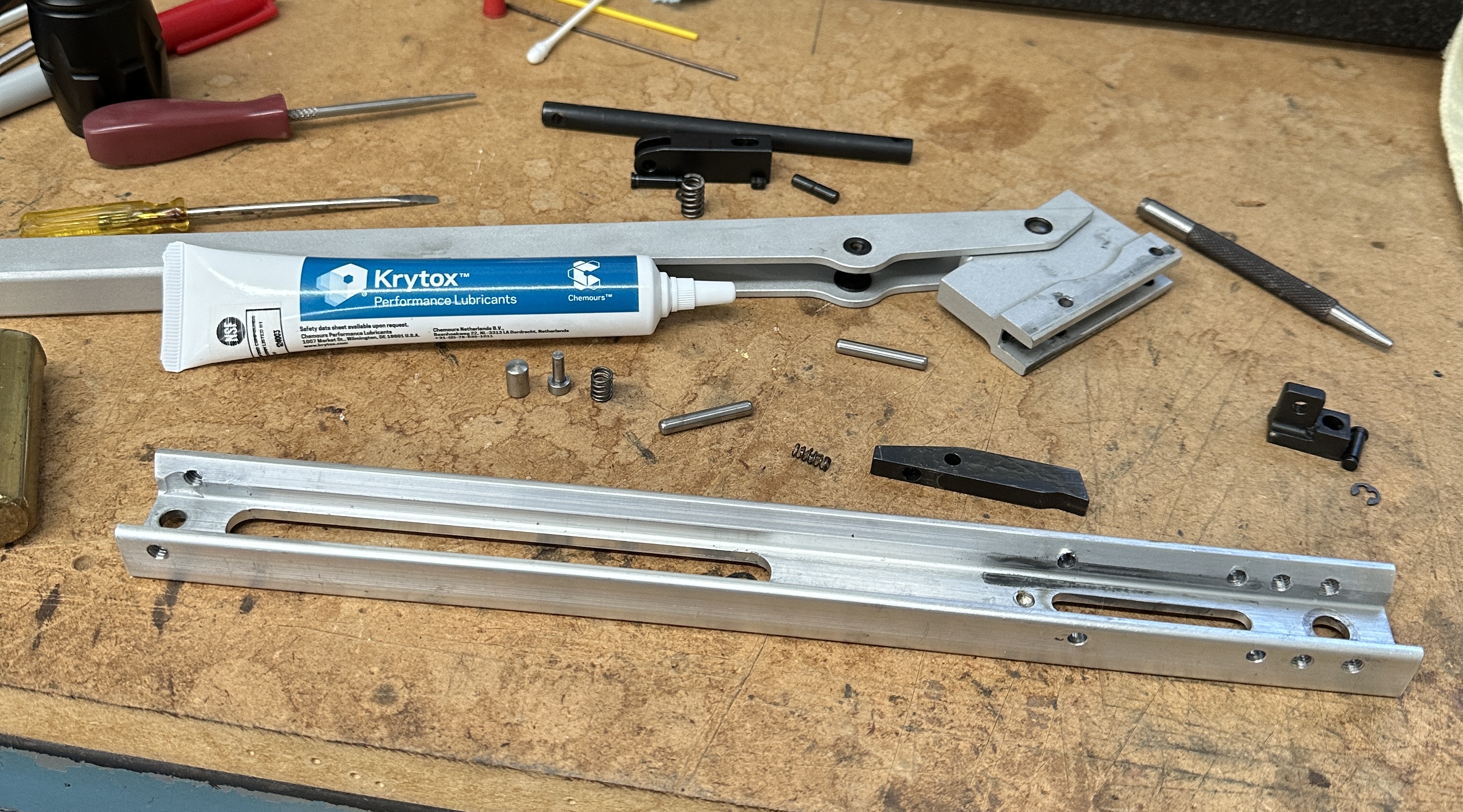

Couldn’t stand it any longer, I had to get inside to see what it looks like, and as I thought it was packed with black grease. After complete disassembly and cleaning/ polishing , I will probably make new guides and top hat for this spring. It will be relubed with Krytox 223 or 205 and continue with my pellet testing. Then I will decide if I want to try a lighter Maccari spring. There’s a lot of possibilities with this rifle, I like the fact that the compression tube and piston have delrin bearings from the factory. Piston seal looks good no cuts in it. Probably go through the trigger too.

Upvote 0

Definitely go through the trigger and polish those sears. You'll thank yourself later. Its a darn easy trigger to disassemble too.Couldn’t stand it any longer, I had to get inside to see what it looks like, and as I thought it was packed with black grease. After complete disassembly and cleaning/ polishing , I will probably make new guides and top hat for this spring. It will be relubed with Krytox 223 or 205 and continue with my pellet testing. Then I will decide if I want to try a lighter Maccari spring. There’s a lot of possibilities with this rifle, I like the fact that the compression tube and piston have delrin bearings from the factory. Piston seal looks good no cuts in it. Probably go through the trigger too.

View attachment 406054

View attachment 406055

View attachment 406056

View attachment 406057

For reference to make your life easier, the factory guide is roughly 0.530" in diameter. It should be closer to 0.560"-0.565"

Last edited:

Upvote 0

Yes the factory guide is pretty loose. Another little thing I don’t like is the bare steel safety catch. I think I’ll slightly radius the sharp corner on it and then cold blue it till I get it as dark as possible..lol.Definitely go through the trigger and polish those sears. You'll thank yourself later. Its a darn easy trigger to disassemble too.

For reference to make your life easier, the he factory guide is roughly 0.530" in diameter. It should be closer to 0.560"-0.565"

Looking through the underside you can see the stop pin hole bushing I made for a snug fit with the stop pin in the picatinny scope rail, this was a

mod I learned from nced and I have it on all my rifles.

Upvote 0

Going back through my notes here a good starting point for the guide is actually 0.570"Yes the factory guide is pretty loose. Another little thing I don’t like is the bare steel safety catch. I think I’ll slightly radius the sharp corner on it and then cold blue it till I get it as dark as possible..lol.

View attachment 406068

Looking through the underside you can see the stop pin hole bushing I made for a snug fit with the stop pin in the picatinny scope rail, this was a

mod I learned from nced and I have it on all my rifles.

View attachment 406076

Upvote 0

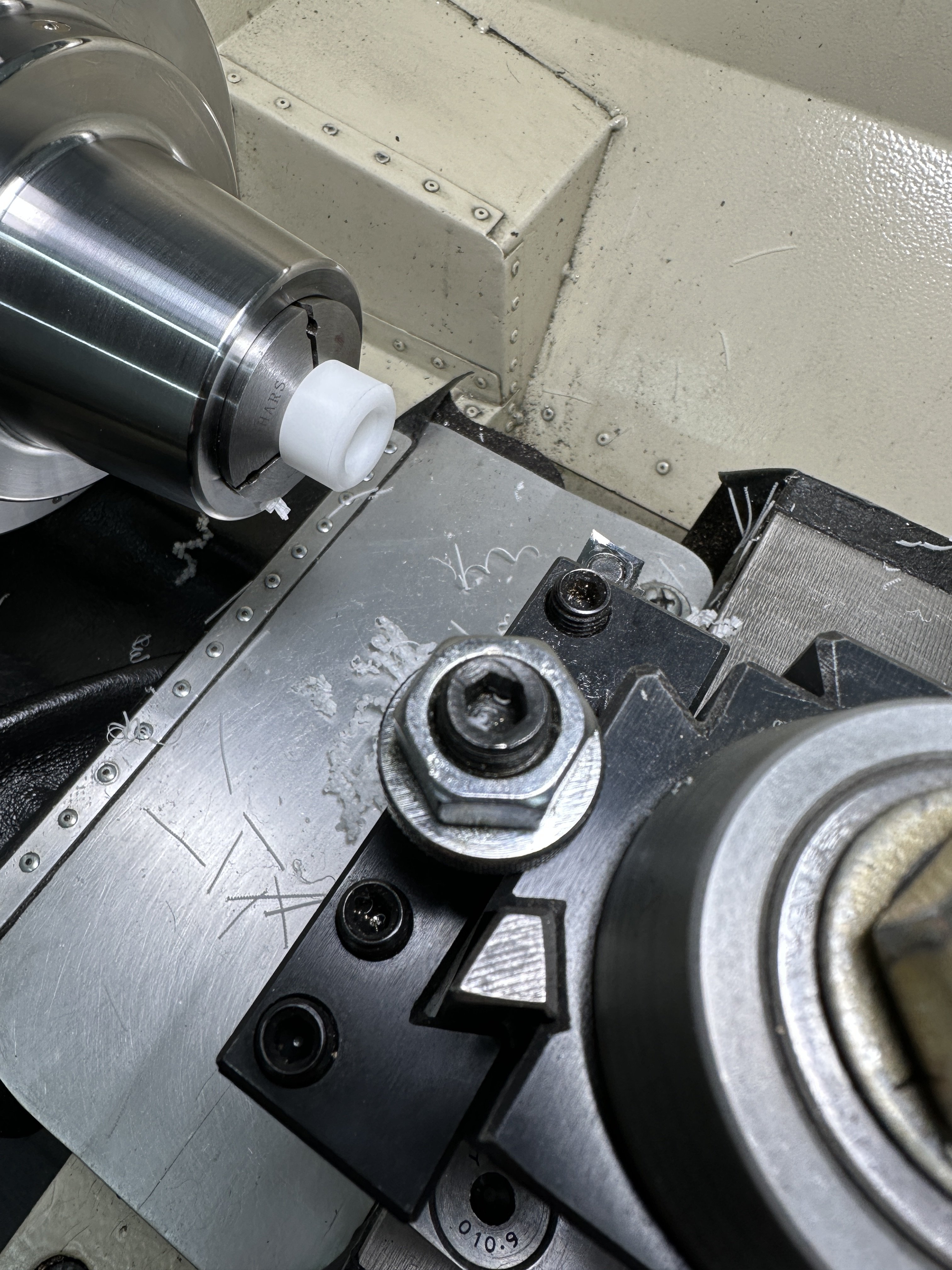

Decided to use a emergency 5C collet to finish the spring guides and it worked way better than last time I made guides. Holds them without smashing them out round and the fit and runout is perfect with bored to size 5C collet. I made the main guide one piece out of 1.25 delrin, still have to finish the back end on it. We’ll see how it works out when it’s back together.

Upvote 0

While I have the trigger all apart for sear polishing I decided to make some custom brass washers to take up the .022 side to side play on the trigger blade. I don’t think all that slop can be doing any good for my trigger break consistency.

Upvote 0

Everything will be completely degreased before relubing with the Krytox 223 so now the rifle has been completely disassembled to the last screw and pin. Which is also good for deburring and polishing parts where needed, important screws will get blue lock tite on reassembly.

I also ran a QYS pellet thru the bore and it was snug till about middle then dropped a couple of inches then snug again till it came out the muzzle, I’m sure my 1/8 wooden dowel rod put pressure inside the skirt and flared it out, but it doesn’t affect the head and it has good rifling cut

in the head.

All that’s left is to put the piston and compression tube in the lathe to break some sharp edges and do a little polishing and it should be ready to reassemble.

I also ran a QYS pellet thru the bore and it was snug till about middle then dropped a couple of inches then snug again till it came out the muzzle, I’m sure my 1/8 wooden dowel rod put pressure inside the skirt and flared it out, but it doesn’t affect the head and it has good rifling cut

in the head.

All that’s left is to put the piston and compression tube in the lathe to break some sharp edges and do a little polishing and it should be ready to reassemble.

Upvote 0

Mabe check the inside of the trigger group where the latch rod connects to the trigger, on my pro sport it was touching the top of the hole when it was installed because the hold-down bolt would pull it down. So I did button the trigger group, stopping it from touching when reassembling. you can tell if it is touching but the paint is rubbed off at the top. I hope this makes sence to you. Steve!

Upvote 0

There is a slight rub mark on top, off center to left. Was yours causing a problem? Are you talking about buttons on the outside of the trigger block? Show a pic if you have it.Mabe check the inside of the trigger group where the latch rod connects to the trigger, on my pro sport it was touching the top of the hole when it was installed because the hold-down bolt would pull it down. So I did button the trigger group, stopping it from touching when reassembling. you can tell if it is touching but the paint is rubbed off at the top. I hope this makes sence to you. Steve!

Upvote 0

I do not have any pictures right now and I did not want to take the rifle apart for a picture, yes I put brass buttons on the trigger block to centre it.

I did it in my lathe and made it a slight push fit and that stopped the rubbing. I also put the piston in my lathe and checked the run out on the piston latch rod it was out a little so I straightened that as well.

It is the smoothest shooting rifle now. I put a pg4h kit in it and it shoots wonderfully. Steve!

I did it in my lathe and made it a slight push fit and that stopped the rubbing. I also put the piston in my lathe and checked the run out on the piston latch rod it was out a little so I straightened that as well.

It is the smoothest shooting rifle now. I put a pg4h kit in it and it shoots wonderfully. Steve!

Upvote 0

The QYS do very well in my AA’s too. That said, they are not 8.48gr as you may notice that they have lower velocities then the JSBs. They are in actuality around 9gr! Tricky marketing by QYS, but quality pellets none the less.

-Marty

-Marty

Upvote 0

Thanks I might look into next time it’s apart, I would use delrin for the bearings but brass is fine. I did check my latch rod today before assembly and best I could get it was .005 I did make my guides with a smaller bore than the factory guides.I do not have any pictures right now and I did not want to take the rifle apart for a picture, yes I put brass buttons on the trigger block to centre it.

I did it in my lathe and made it a slight push fit and that stopped the rubbing. I also put the piston in my lathe and checked the run out on the piston latch rod it was out a little so I straightened that as well.

It is the smoothest shooting rifle now. I put a pg4h kit in it and it shoots wonderfully. Steve!

Upvote 0

Have you weighed any? The ones I weighed were pretty close although I didn’t check very many.The QYS do very well in my AA’s too. That said, they are not 8.48gr as you may notice that they have lower velocities then the JSBs. They are in actuality around 9gr! Tricky marketing by QYS, but quality pellets none the less.

-Marty

My prosport was doing about 890fps with them before I took it apart.I’m going to chrony tonight to check it post tune numbers.

Upvote 0

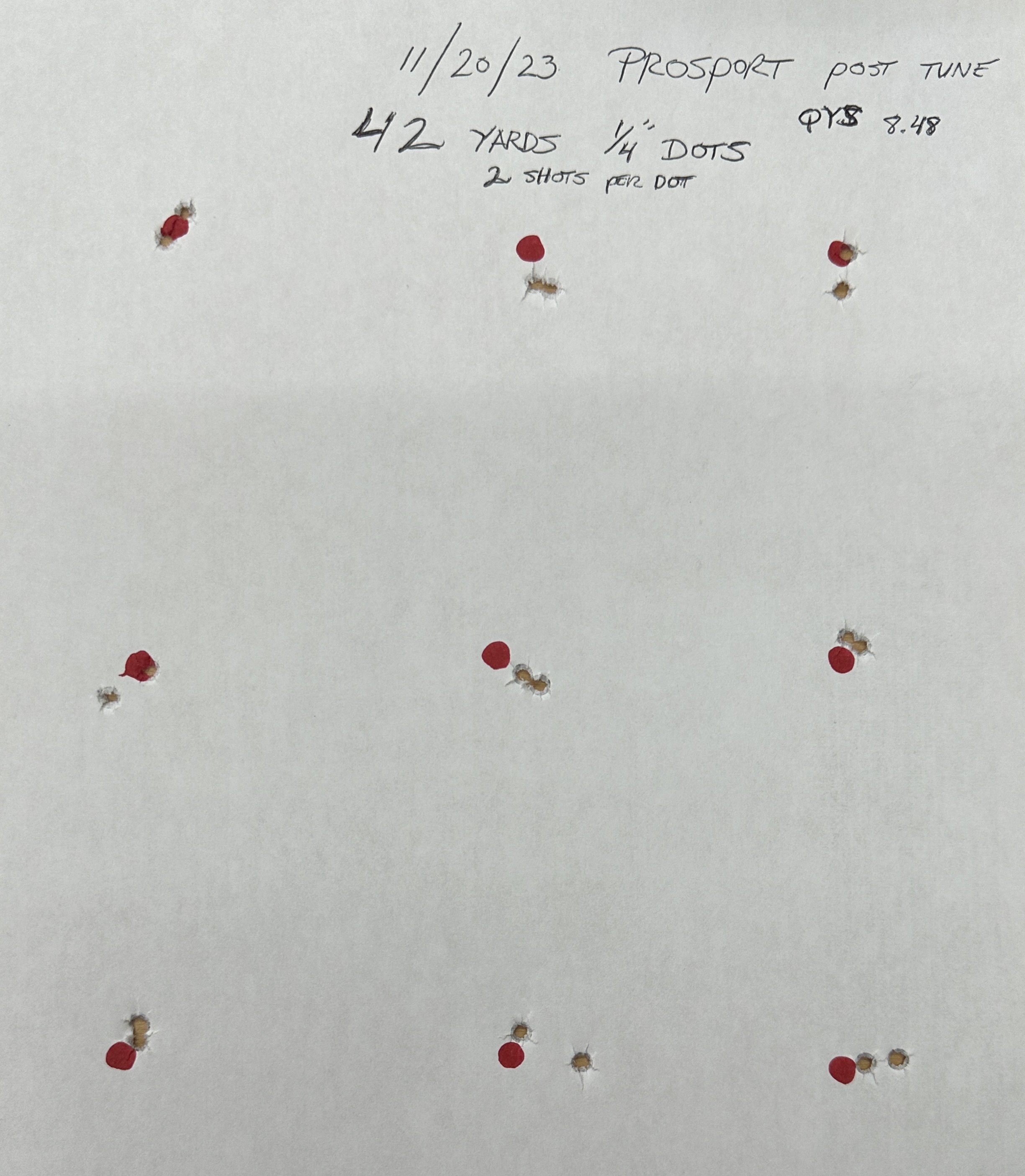

Finished up the prosport tune this afternoon and did some test shooting with the QYS 8.48 at 42 yards at 1/4” dots. I’m liking the trigger and the action is smoother, I’m going to chrony it tonight to see if the numbers went up or down. I’m thinking when I first got it and started shooting that every now and then I smelled something like smoke, so it may have been burning some of that black goo that was packed inside..lol.

All back together….

Testing after reassembly….

All back together….

Testing after reassembly….

Upvote 0

It seems to have picked up a hair now, it’s averaging right at 900fps with the QYS 8.48, but I didn’t weigh any of those. Now it’s time to put some pellets through it and get used to it.

And I’m also liking the blued safety catch.

And I’m also liking the blued safety catch.

Upvote 0

Yes, just a day or two ago. I used a jeweler’s scale. I was surprised that the weights were from 8.92-9.06. This is not uncommon with their other line too…Have you weighed any? The ones I weighed were pretty close although I didn’t check very many.

My prosport was doing about 890fps with them before I took it apart.I’m going to chrony tonight to check it post tune numbers.

QYS Domed 9.56gr pellet test with Mike Morton - Airgun Magazine

QYS’s Domed pellet is joined by a heavier sibling, and Mike Morton finds out whether a little extra weight will make it great

-Marty

Upvote 0

Thanks for the info, and great target group. Looking forward to joining you guys by becoming a prosport owner. If it’s more accurate than my tricked out 97K I’ll be surprised for sure.

I would be surprised also if it shoots as good as my HW 97k But really like the looks of that gun

Last edited:

Upvote 0

Time will tell.I would be surprised also if it shoots as good as my HW 97k But really like the looks of that gun

Upvote 0