Hi,

I recently bought a bottle adapter for the AEA HP and while I ordered the adapter for the HP SS

I received an adapter for the HP SF

The online store is not replying to any of my emails when I ask them about the

mistake they made, so I am trying to find out if this adapter is able to withstand

the working pressure of the HP SS (250 bar)

While the threads of the gold adapter are of the same thickness all the way,

the threads if the SF black adapter are very thin during the first 12mm and then

thick the rest 10mm as you can see at the photo below:

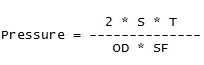

According to Barlow's formula which calculates the working pressure of a pipe we have the following:

where:

S = Ultimate Tensile Material Strength = 45.000 PSI assuming they are using 6061 aluminum.

T = Pipe Wall Thickness = 0.071" the thin wall and 0.191" the thick wall.

OD = Outside Diameter = 0.701"

SF = Safety Factor = 3

So based on the above, the working pressure of the thin wall is 3038 PSI = 209 BAR

and the working pressure of the thick wall is 8259 PSI = 569 BAR

(the bursting pressure is much higher) Please correct me if I am wrong.

So we have an adapter thread in which the 12mm are able to handle 209 bar

and the 10mm are able to handle 569 BAR.

Do you think that this adapter is not safe to use with the 250 BAR bottle pressure

that I will use in the carbon fiber bottle?

Thank you.

I recently bought a bottle adapter for the AEA HP and while I ordered the adapter for the HP SS

I received an adapter for the HP SF

The online store is not replying to any of my emails when I ask them about the

mistake they made, so I am trying to find out if this adapter is able to withstand

the working pressure of the HP SS (250 bar)

While the threads of the gold adapter are of the same thickness all the way,

the threads if the SF black adapter are very thin during the first 12mm and then

thick the rest 10mm as you can see at the photo below:

According to Barlow's formula which calculates the working pressure of a pipe we have the following:

where:

S = Ultimate Tensile Material Strength = 45.000 PSI assuming they are using 6061 aluminum.

T = Pipe Wall Thickness = 0.071" the thin wall and 0.191" the thick wall.

OD = Outside Diameter = 0.701"

SF = Safety Factor = 3

So based on the above, the working pressure of the thin wall is 3038 PSI = 209 BAR

and the working pressure of the thick wall is 8259 PSI = 569 BAR

(the bursting pressure is much higher) Please correct me if I am wrong.

So we have an adapter thread in which the 12mm are able to handle 209 bar

and the 10mm are able to handle 569 BAR.

Do you think that this adapter is not safe to use with the 250 BAR bottle pressure

that I will use in the carbon fiber bottle?

Thank you.