For those of us that do our own gun smithing on air rifles for Benchrest (with a capital B), what do you prefer for a target type crown?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Air Rifle Benchrest Competition Barrel Crowns

- Thread starter pbike257

- Start date

No preference to a particular geometry in terms of performance...some are more aesthetically pleasing than others, or offer varying degrees of protection from abuse (which should be irrelevant for a precision benchrest gun). Square/uniform to the bore and burr-free is what I care about. A simple bevel applied with the brass screw technique can work very nicely:

As this fly leisurely checking out the target at 30 yards found out...

As this fly leisurely checking out the target at 30 yards found out...

Upvote 0

Square and symmetrical over any fancy angle works just fine. 90* with CRATEX point corner break works just fine or as shown above.

NO BURRS is key !!!!

NO BURRS is key !!!!

Upvote 0

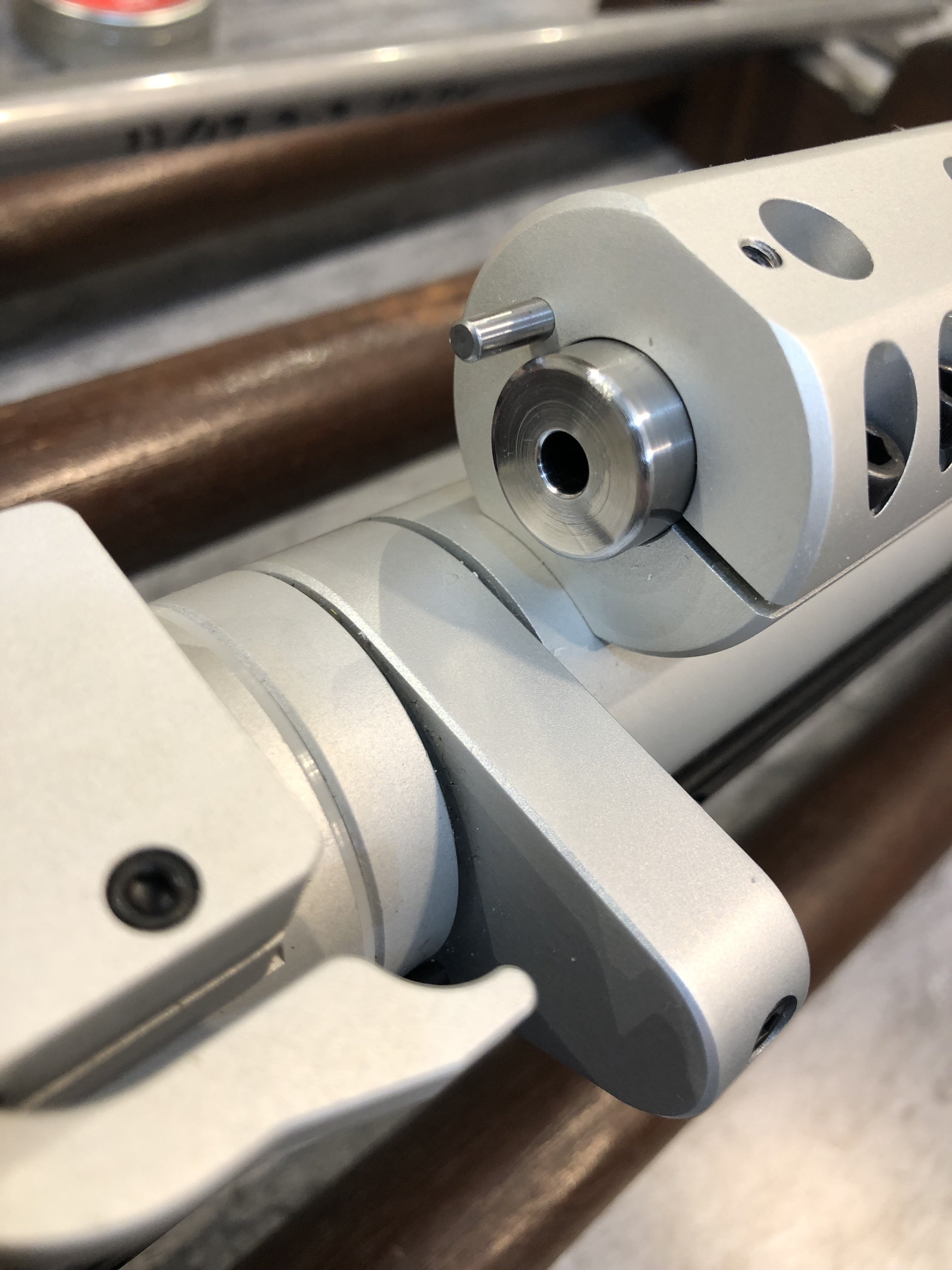

On the lathe when crowning a barrel you need to make sure it is absolutely concentric with the bore. You can set the barrel in a 4 jaw chuck and clock the bore, but with the rifling it is bit difficult, my chosen method is to grab the barrel at the breech end and run a center in the bore at the tailstock end. Then cut a small band on the outside of the barrel and that band will then be 100% concentric with the bore and then returning to the 4 jaw chuck you can clock the band 100% true and then the bore is also perfectly concentric, Then with a very sharp tool cut the crown from the inside out. I don't think the angle of the crown is critical. If you did a 45 degree crown, take a 45 degree mandrel and with some 600 grit waterpaper carefully polish the crown in both directions, clockwise and anticlock. You will the have the perfect crown!

Upvote 0

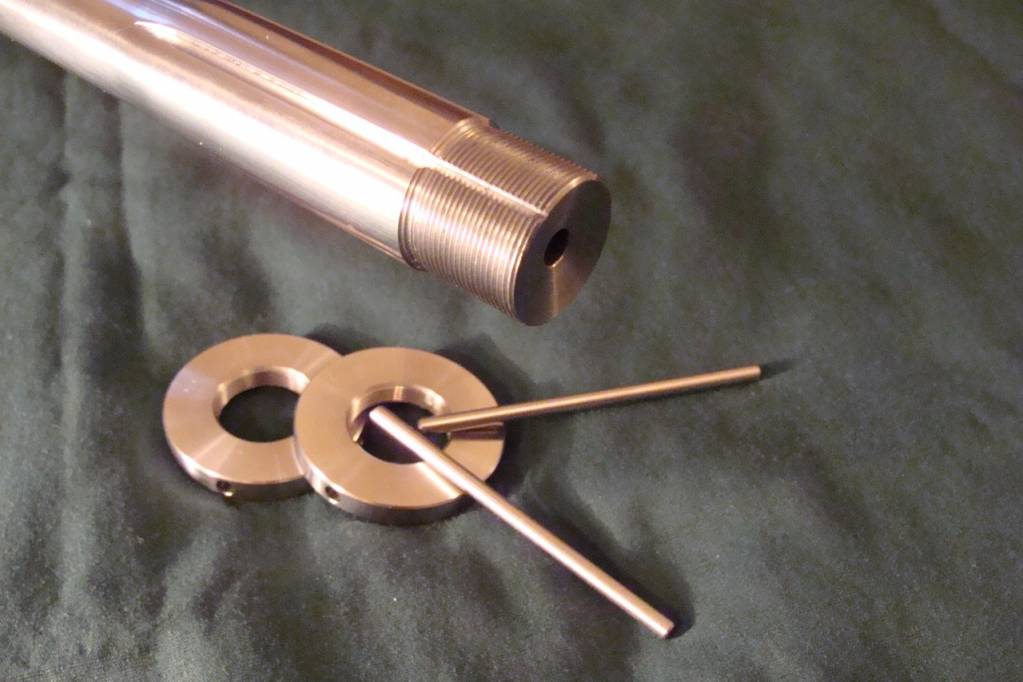

So Here are a few crowns I've done. I've done many crowns, and I saw one a few weeks ago from a very distinguished gunsmith... But it kind of blew my mind how different it was from what I am accustomed to seeing on "match grade rifles". Like was mentioned... I cut them absolutely square and concentric to the bore for the crown cutting set up. also absolutely clean and polished with "cratex" rubber rods, down to "black" very fine. These two crowns happen to also be threaded for tuners, which work very well. I prefer a 45 degree cut coming out of the barrel, then an Eleven degree as you can see. I have shot benchrest for about 30 years, and I know that many use a flat or square crown. It hasn't mattered for me and I just happen to do well with the 11 degree. I am rather new to Airgun and was looking to see if there are differing ideas... It seems not.

Upvote 0

The idea of the 11 degree taper is to avoid bumping the crown and damaging it I suppose, or does it have another function?

I also like the barrel tuner idea, is the thread long enough to make a difference?

I also like the barrel tuner idea, is the thread long enough to make a difference?

Upvote 0

The 11 degree came from powder burner of course, and it was to allow flow of gases away from the bullet quickly and evenly.

The threaded area only needs to be 3/4 inch long, I can take a rifle in and out of tune within 1/2 revolution. the tuners are 1/4" thick and unf 28 tpi thread.

The threaded area only needs to be 3/4 inch long, I can take a rifle in and out of tune within 1/2 revolution. the tuners are 1/4" thick and unf 28 tpi thread.

Upvote 0

I dug through some old photos and found this picture, I know I could probably get a better picture, but much like tying flies and taking pictures, the better the picture, the worse your tie looks... I think this crown is bad enough that I don't need a better picture. This crown was the reason for this thread originally.

Upvote 0

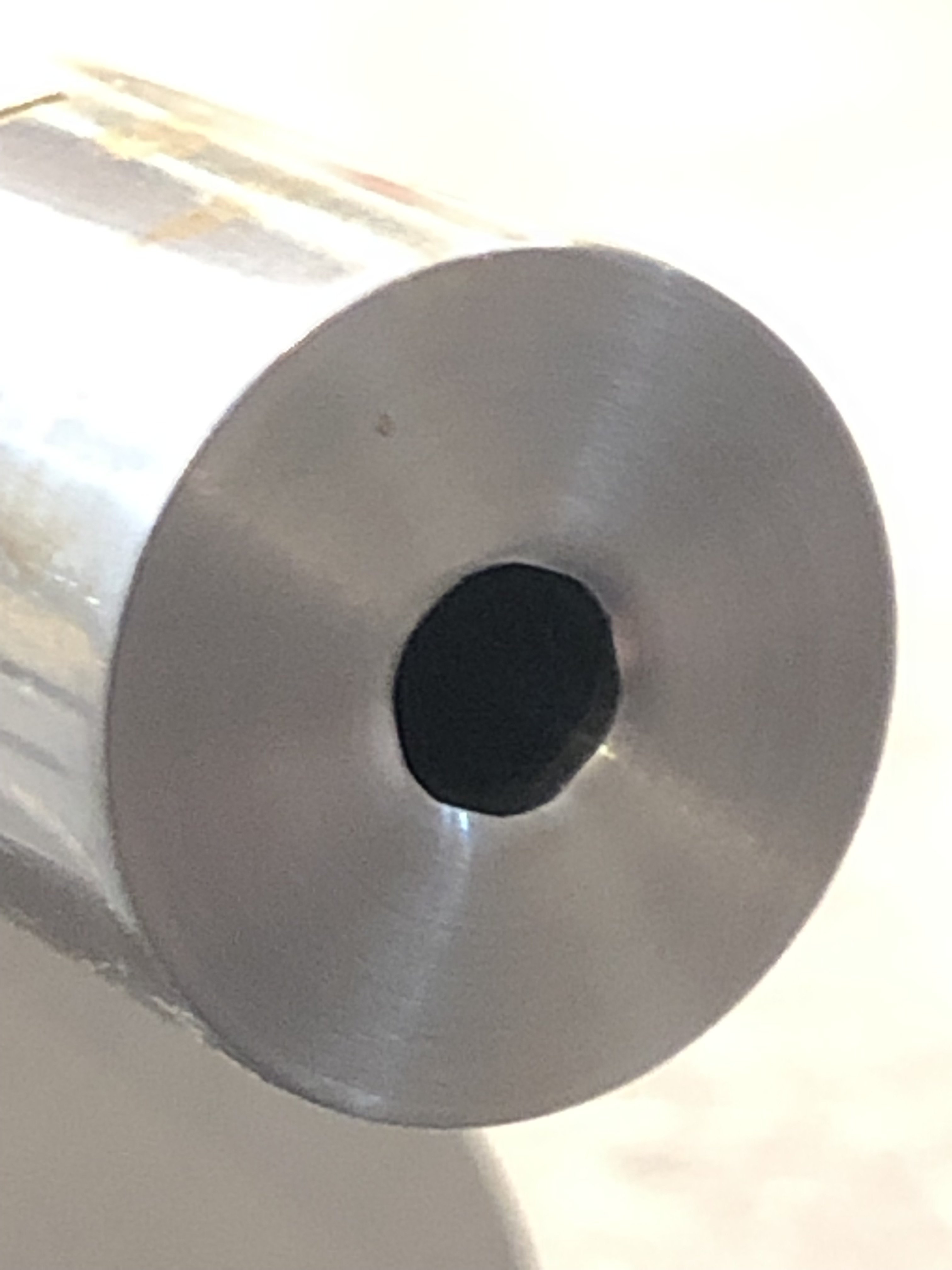

Well after a few days at work and thinking about that crown... I went down to the shop in the basement and popped the barrel out of the rifle then went up to the garage and did not only the crown, but I tuned up the breach end as well. The breach wasn't near as smooth as I wanted since the O-ring seals that up. Here's how my crown came out... Not the same style as the original, but it seems to shoot the 50 foot target in the basement pretty well.

Upvote 0

Regarding the original photo, can you describe what defects you’re picking up? I’m having a hard time spotting it. The thing about crowns on polygonal barrels, the bore profile doesn’t produce the subjectively pretty appearance of a conventionally rifled barrel...

...but what matters is merely that it is square to the bore and burr-free.

Whatever the case, hopefully the rework proves successful. Please report back when you have the opportunity to do more testing at range.

...but what matters is merely that it is square to the bore and burr-free.

Whatever the case, hopefully the rework proves successful. Please report back when you have the opportunity to do more testing at range.

Upvote 0

Well, lucky for me we had an Ice storm and I was out of work for a couple days... managed to get some things done around the house and this evening I was able to test that air rifle with its new crown, and breach work in the basement range 50 foot (48 actually).

Before the re-crown and breach work, my NRA AirGun 5/10 Meter targets I was averaging 99-3x over 6 targets. That's a score of 594-18, or two aggregates of 297-9x.

Tonight I shot 6 targets and averaged 99.6667 with 5.3Xs which come out to a total score of 598-32x, or two aggregates of 299-16x

That's an improvement. I still have a few little things to work on but I'm finally getting somewhere.

You'll also notice as I forgot to mention above that I put a pretty decent smooth round over on the edge of the barrel where the white O-ring slides against the edge of the barrel to lock the breach of the barrel air tight. I had to replace that O-ring recently because of excessive wear. Putting a good polish and smooth ramp has hopefully cured that.

Before the re-crown and breach work, my NRA AirGun 5/10 Meter targets I was averaging 99-3x over 6 targets. That's a score of 594-18, or two aggregates of 297-9x.

Tonight I shot 6 targets and averaged 99.6667 with 5.3Xs which come out to a total score of 598-32x, or two aggregates of 299-16x

That's an improvement. I still have a few little things to work on but I'm finally getting somewhere.

You'll also notice as I forgot to mention above that I put a pretty decent smooth round over on the edge of the barrel where the white O-ring slides against the edge of the barrel to lock the breach of the barrel air tight. I had to replace that O-ring recently because of excessive wear. Putting a good polish and smooth ramp has hopefully cured that.

Last edited:

Upvote 0

Facing it off square is very likely to get it concentric, and if you do it within a recesses it will be protected from bumps. Get rid of tiny burrs with brass screw/lapping method and alls well.On the lathe when crowning a barrel you need to make sure it is absolutely concentric with the bore. You can set the barrel in a 4 jaw chuck and clock the bore, but with the rifling it is bit difficult, my chosen method is to grab the barrel at the breech end and run a center in the bore at the tailstock end. Then cut a small band on the outside of the barrel and that band will then be 100% concentric with the bore and then returning to the 4 jaw chuck you can clock the band 100% true and then the bore is also perfectly concentric, Then with a very sharp tool cut the crown from the inside out. I don't think the angle of the crown is critical. If you did a 45 degree crown, take a 45 degree mandrel and with some 600 grit waterpaper carefully polish the crown in both directions, clockwise and anticlock. You will the have the perfect crown!

Upvote 0