I posted a thread a couple weeks ago on a potential fix for an issue that is known to afflict many Airmaks Caimans. This is characterized as a slowly descending shot speed that takes place gradually as air tube pressure decreases, in spite of the presence of a regulator. In my original thread, I performed a modification of the reg that involved replacing what seemed to be a soft plastic piston seal with a delrin disc. You can read about it here:

Long post, but if you’re suffering with an unruly Airmaks Caiman, it might be worth a read: I just picked up an open box Caiman 177 from UA for $800. It will be a gift for a relative who keeps borrowing my Leshiy Classic 🧐 I set it up with a simple but useful Vortex Spitfire 5X prism and an...

www.airgunnation.com

When I put the gun back together, the issue seemed to be fixed, but upon further use over the next few days, the symptom of descending shot speed returned. My Caiman was shooting at 920fps at 270bar, 880fps when tube pressure reduced to 220bar and 840fps at 170bar. All in spite of having the reg set at 110bar. In frustration, I then switched to the use of a Lane Katran regulator, which I had acquired earlier. To my surprise, it exhibited the exact same issue!

This led me to engage in an extensive study of regulator function, using a wide range of online resources. I won’t go into technical details, but I came to the conclusion that the reg was likely not breathing (venting to atmosphere) adequately. This typically yields a gradual increase in plenum pressure that makes the valve harder to open with the same hammer strike, releasing less air and resulting in declining shot speed.

I decided to dive in to the internals again to investigate. The caiman air tube is a two piece affair with a plenum, valve and transfer port in one piece that screws into the main air tube such that the threads on the plenum piece intersect with a breathing hole for the reg that is drilled into the air tube. A pretty common design that allows the reg to vent to atmosphere through the threads. The reg itself press fits into the plenum and is sealed at its distal end by an Oring inside the plenum and at its proximal end by another Oring that sits in the air tube beyond its vent hole. So the idea is that the reg can vent between those two Orings and air can escape through the threads. To facilitate this goal, Airmaks put a chamfer on the shoulder of the plenum where the regulator presses into it, such that air can escape from the reg vent hole and pass into the threads. However, there is a collar on the regulator that allows it to be pressed firmly against the (very flat and smooth) end of the plenum once the tube is filled with high pressure air. The underlying assumption here must be that these two metal surfaces can’t generate a good enough seal to prevent air from passing into the threads and venting. However, my inspection of the system indicates that this is the only potential design flaw that could lead to a failure to vent. Fortunately, I could see a very simple and low risk fix for this “putative” issue that essential amounts to roughing up this joint such that it can’t provide a seal. So I set about filing a small groove at the end of the plenum (which the reg collar presses against) so that it can’t possibly be air tight. This should allow air to escape through the gap and access the threads and subsequently, the air tube breathing hole. Lo and behold, it has been working like a charm with the gun shooting at 920fps from 300bar to 120bar. I’ve tested 8 refills over the course of the past 5 days and there has been absolutely no hint of the problem. I’ve also replicated the original problem by artificially sealing the tube vent hole. Sure enough the descending shot speed returned (in a more aggressive form). Removing the seal then relieves the problem. Therefore, at this point, I’m very confident in my findings and proposed fix. It works with either the original or Lane reg and I suspect that it’ll work without any of the other fixes that I documented in my original thread.

I realize that the Caimans are not the most popular bullpups out there, but if you’re saddled with one that has this affliction, this free and easy fix might be worth a shot. All you need to do is degas and remove the air tube, unscrew the plenum (the reg will remain stuck in the air tube), file a tiny slot into the end of the plenum (just before the threads begin) and put things back together. It’s a 15 min job and you don’t have to mess with the reg settings or retune.

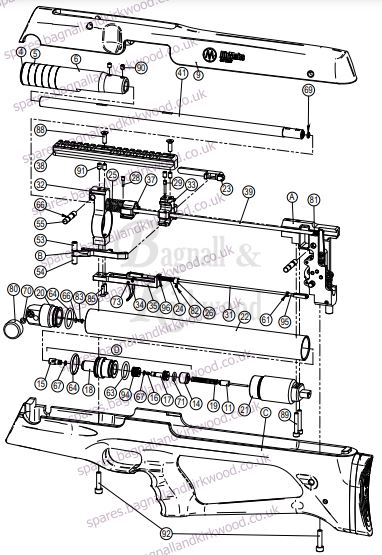

On the following schematic the little slot is filed at the end of the plenum, exactly where the number (21) is shown:

Please find below the exploded parts diagram, parts list and available spare parts for the AirMaks Caiman & Caiman X air rifle. Exploded Parts Diagram: Available Spare Parts: Here at Bagnall and Kirkwood we stock many spare parts for your gun. From springs to seal kits, o-rings to breech seals...

spares.bagnallandkirkwood.co.uk

Finally, I also know that some Caiman owners don’t seem to have this issue. MikeVV, on here, for example… Based on my discoveries, I would posit that some guns may have plenums that aren’t machined perfectly and therefore don’t generate an air tight seal against the collar of the reg.