So how far can you optimize an Akela using all stock parts…?

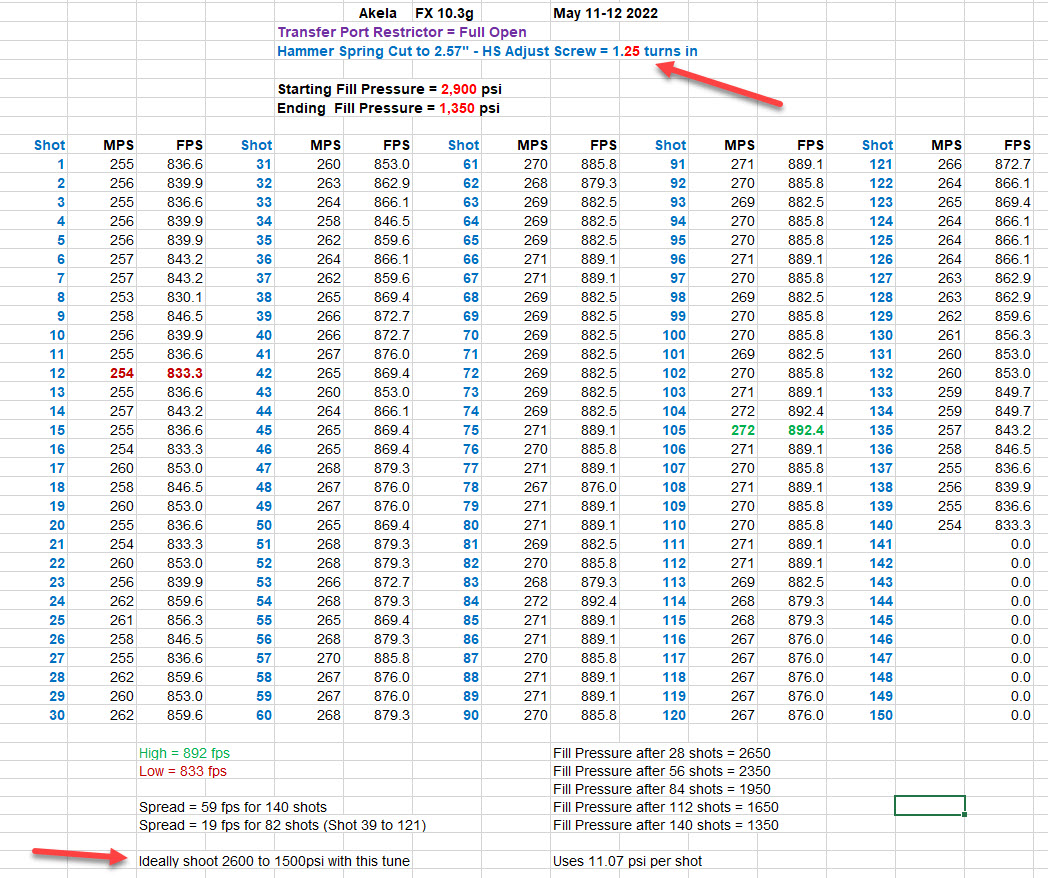

On another forum (GTA) I was the originator of cutting the stock 3.5” hammer spring down to 2.57” on the .177 Akela.

That spring length worked so well that I never optimized further.

Lately I polished most every part in my Akela and Cayden.

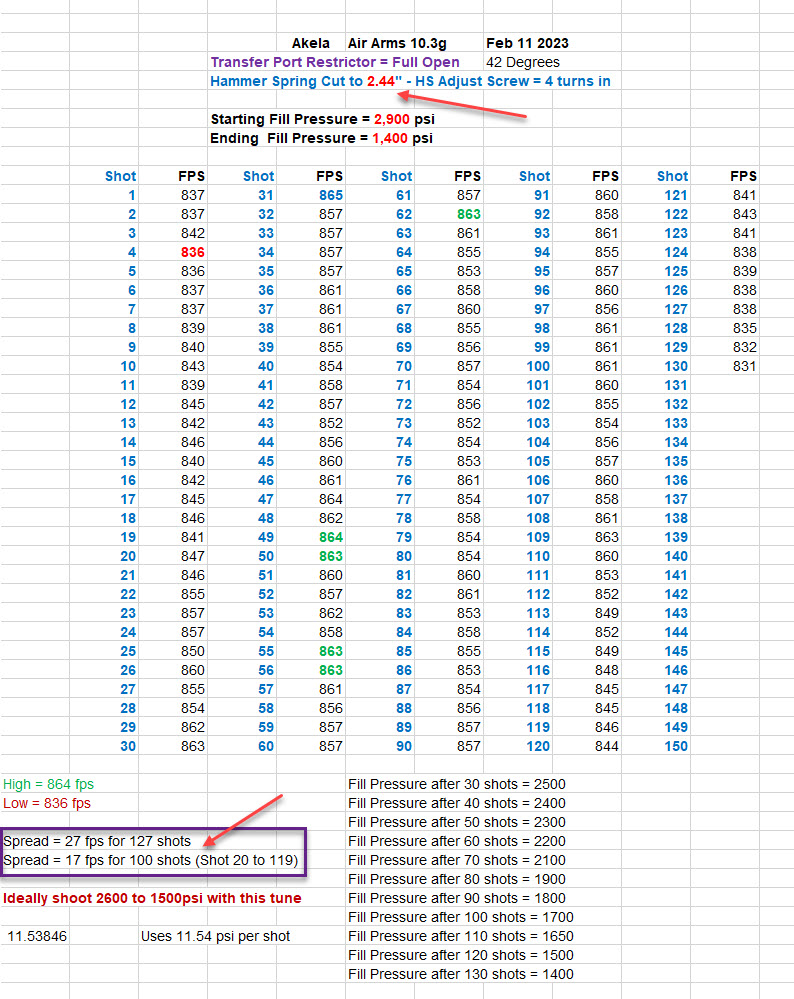

Today I shortened a stock hammer spring to 2.44” (flattened the cut end with a Dremmel butane torch) - to see if I could get an even tighter shot string.

I polished the hammer, inside the hammer where the spring rides and the 2.44” spring itself. I used a little dry lock lube inside the hammer and then reassembled the rifle after taking 4 shots with chrony and getting the hammer spring adjuster set to shoot around 850fps.

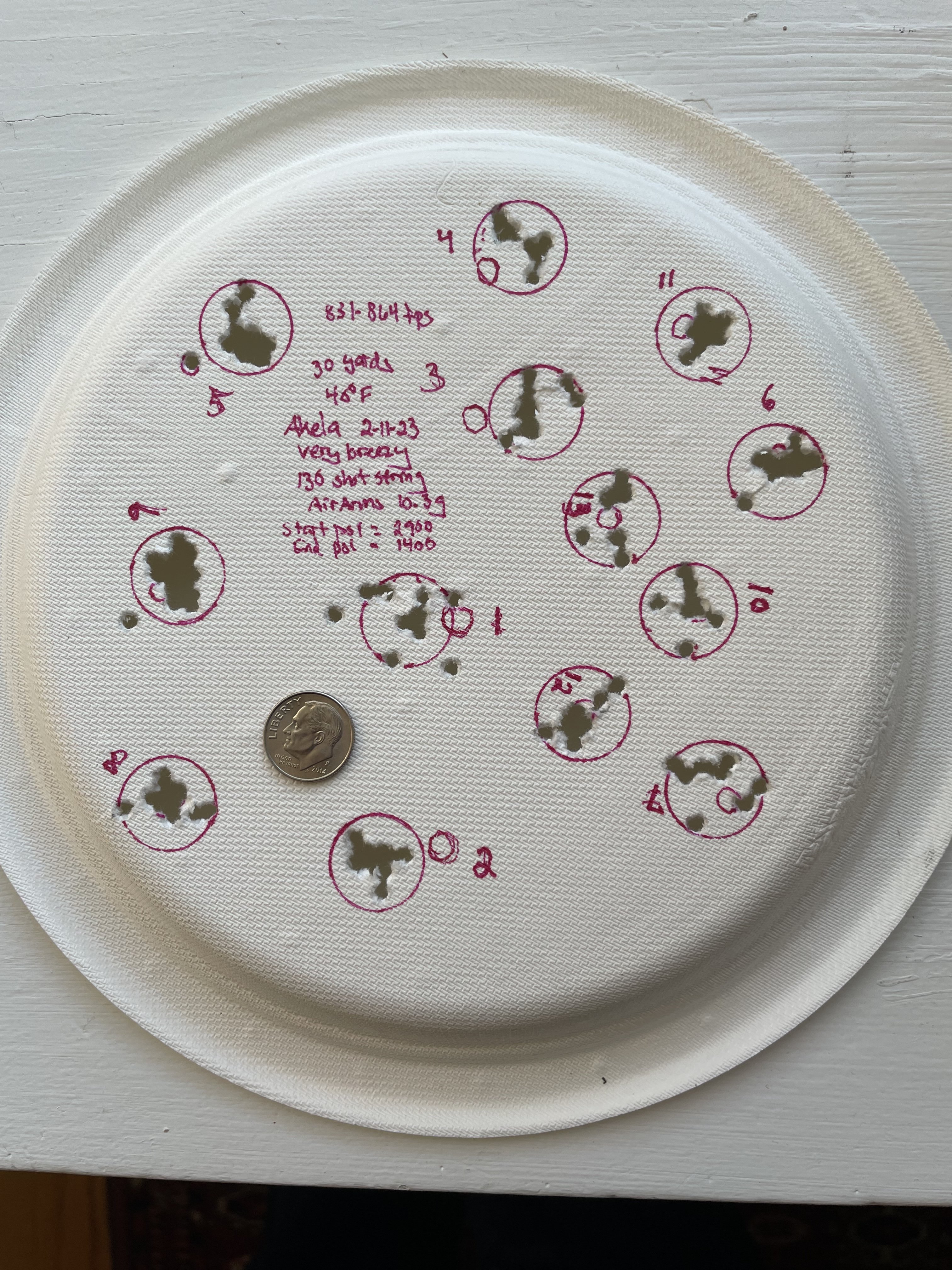

I took it outside and shot 13 ten-shot groups into a paper plate at 30 yards (91.26 feet). It was too windy to target shoot the 30 Yard Challenge, so I figured why not see what the Akela’s shot string looked like.

This will probably get better once the spring “settles in” - as these are basically the 1st 130 shots after reassembly.

The result is a 17fps spread over 100 shots. Yep, you read that correctly, 17 fps spread over 100 shots from an unregulated air tube rifle shooting 847-864fps - single fill. Shot from 2900 psi down to 1400psi.

Take a look at the 30 yard 10-shot groups on a windy 42 degree day - with the exception of group 1 where I was adjusting the scope, all groups fit under a dime.

Group 13 got me think I may want to REDUCE velocity into the 833-843fps range - as 7 of the 10 pellets went into a hole the size of 2 .177 pellets (wind blew the other 3 to the right).

I’m also including a shot string I ran with the 2.57” spring - for comparison. That shot string was at slightly higher velocity.

I paid $350 bucks for this rifle on Crosman’s Father’s Day sale. It’s amazing how great they can be with a little elbow grease put into them - no money, just effort.

-Ed

On another forum (GTA) I was the originator of cutting the stock 3.5” hammer spring down to 2.57” on the .177 Akela.

That spring length worked so well that I never optimized further.

Lately I polished most every part in my Akela and Cayden.

Today I shortened a stock hammer spring to 2.44” (flattened the cut end with a Dremmel butane torch) - to see if I could get an even tighter shot string.

I polished the hammer, inside the hammer where the spring rides and the 2.44” spring itself. I used a little dry lock lube inside the hammer and then reassembled the rifle after taking 4 shots with chrony and getting the hammer spring adjuster set to shoot around 850fps.

I took it outside and shot 13 ten-shot groups into a paper plate at 30 yards (91.26 feet). It was too windy to target shoot the 30 Yard Challenge, so I figured why not see what the Akela’s shot string looked like.

This will probably get better once the spring “settles in” - as these are basically the 1st 130 shots after reassembly.

The result is a 17fps spread over 100 shots. Yep, you read that correctly, 17 fps spread over 100 shots from an unregulated air tube rifle shooting 847-864fps - single fill. Shot from 2900 psi down to 1400psi.

Take a look at the 30 yard 10-shot groups on a windy 42 degree day - with the exception of group 1 where I was adjusting the scope, all groups fit under a dime.

Group 13 got me think I may want to REDUCE velocity into the 833-843fps range - as 7 of the 10 pellets went into a hole the size of 2 .177 pellets (wind blew the other 3 to the right).

I’m also including a shot string I ran with the 2.57” spring - for comparison. That shot string was at slightly higher velocity.

I paid $350 bucks for this rifle on Crosman’s Father’s Day sale. It’s amazing how great they can be with a little elbow grease put into them - no money, just effort.

-Ed