Hey, fellow Epoch enthusiasts. I’m reaching out to find out how many of you are interested in eliminating the inline bottle shut off valve in favor for an adapter much like what’s attached on the front of most FX platforms, so at any time the pressurized bottle can be removed safely without losing any of the air in the bottle. The great thing about these Skout Epoch platforms is the air bleed off knob on the side of the chassis, so the entire action can be drained down of all air once the bottle is removed.

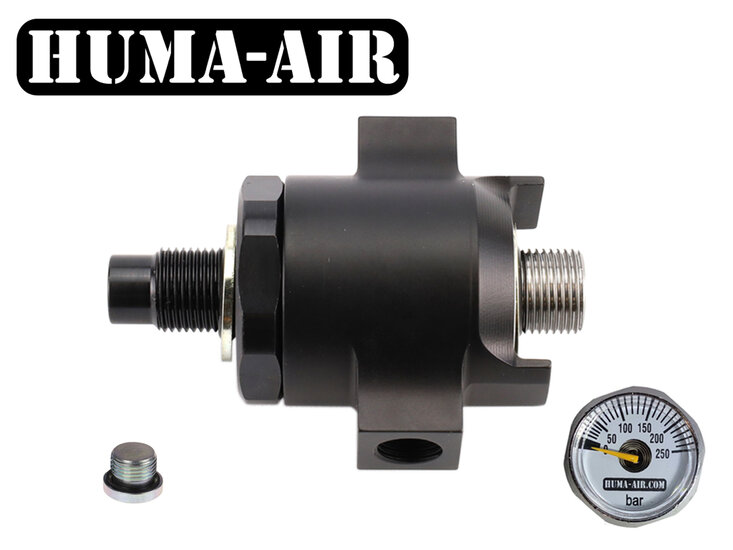

I’ve been having back and forth emails with Marc at Huma to come up with this design, and possibly take it another step in where a first stage inline regulator can be designed for this gun much so like they did for the MK1 and MK2 Impacts, in where there are side “tongs” to hug the sides of the chassis giving the addition of a first stage reg a more aesthetic look.

For those of you not familiar with that mod, here’s the link. Probably the best mod overall that I’ve added to my pre M3 impacts, in helping its overall performance-

huma-air.com

huma-air.com

But that would be later down the line if Huma would consider taking that next step. For now it’s the bottle adapter I’m reaching out to all of you for mainly. Huma said if 30 or more folks would be interested in purchasing this adapter, they would move forward in its design and fabrication.

Here would be the pluses to having this adapter-

1. Pressurized bottle can safely be removed with very minimal loss of air

2. No more inline shut off valve that is prone to leaking surprisingly- not bagging on Skout for utilizing this inline valve, as it is recommended that the entire gun be drained of its air after use, but that tiny 003 o ring has twice failed on me, leaving me with all air emptied out of the bottle while shooting at home

3. It will shorten the length of the bottle to chassis connection, giving the Epoch platform an overall better look, aesthetically.

So, fellow Skout Epoch owners, if you are interested in this bottle to chassis adapter, please reply on this thread as I am forwarding this thread to Huma, to see if there is a want/need for this adapter. I’m guessing if Huma moves forward with this, they will sell both the bottle to chassis adapter along with an FX style 300 bar rated bottle valve in kit form, so two parts, maybe.

Thank you

I’ve been having back and forth emails with Marc at Huma to come up with this design, and possibly take it another step in where a first stage inline regulator can be designed for this gun much so like they did for the MK1 and MK2 Impacts, in where there are side “tongs” to hug the sides of the chassis giving the addition of a first stage reg a more aesthetic look.

For those of you not familiar with that mod, here’s the link. Probably the best mod overall that I’ve added to my pre M3 impacts, in helping its overall performance-

FX Impact MKI-MKII First Stage Tuning Regulator by Huma-Air

FX Impact MKI MKII first stage regulator what will flatten out all pressure fluxtuations over the full pressure range of your bottle for extreme accuracy.

But that would be later down the line if Huma would consider taking that next step. For now it’s the bottle adapter I’m reaching out to all of you for mainly. Huma said if 30 or more folks would be interested in purchasing this adapter, they would move forward in its design and fabrication.

Here would be the pluses to having this adapter-

1. Pressurized bottle can safely be removed with very minimal loss of air

2. No more inline shut off valve that is prone to leaking surprisingly- not bagging on Skout for utilizing this inline valve, as it is recommended that the entire gun be drained of its air after use, but that tiny 003 o ring has twice failed on me, leaving me with all air emptied out of the bottle while shooting at home

3. It will shorten the length of the bottle to chassis connection, giving the Epoch platform an overall better look, aesthetically.

So, fellow Skout Epoch owners, if you are interested in this bottle to chassis adapter, please reply on this thread as I am forwarding this thread to Huma, to see if there is a want/need for this adapter. I’m guessing if Huma moves forward with this, they will sell both the bottle to chassis adapter along with an FX style 300 bar rated bottle valve in kit form, so two parts, maybe.

Thank you