After a lot of work on shroud, silencer, barrel polishing etc. I concluded that the barrel is not holding point of Impact.

Just like FX Impact, this Daystate's barrel is also locked by one grub screw at the rear end. While only the O rings are providing support to the rest of the barrel which is not enough to hold the POI.

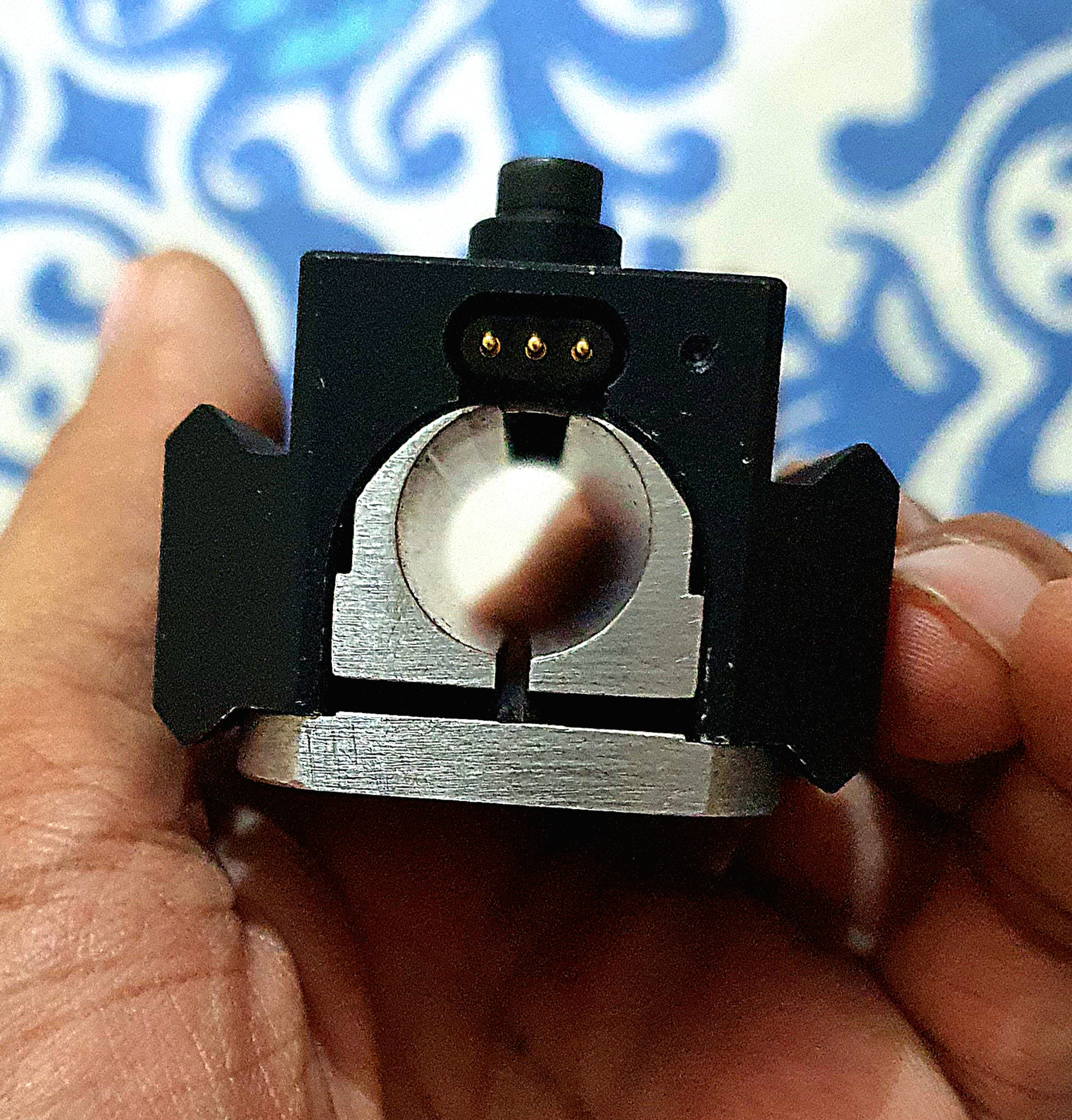

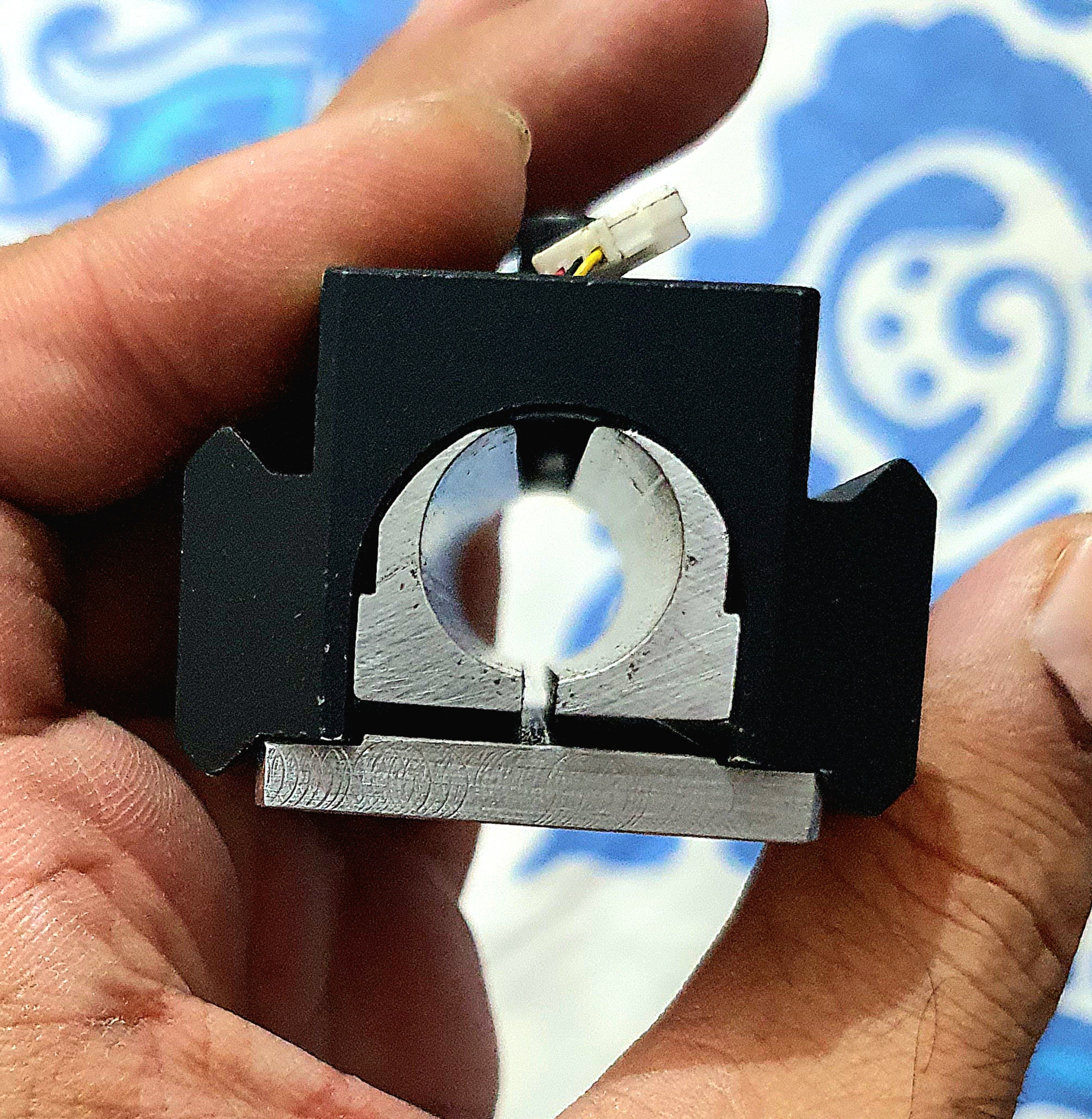

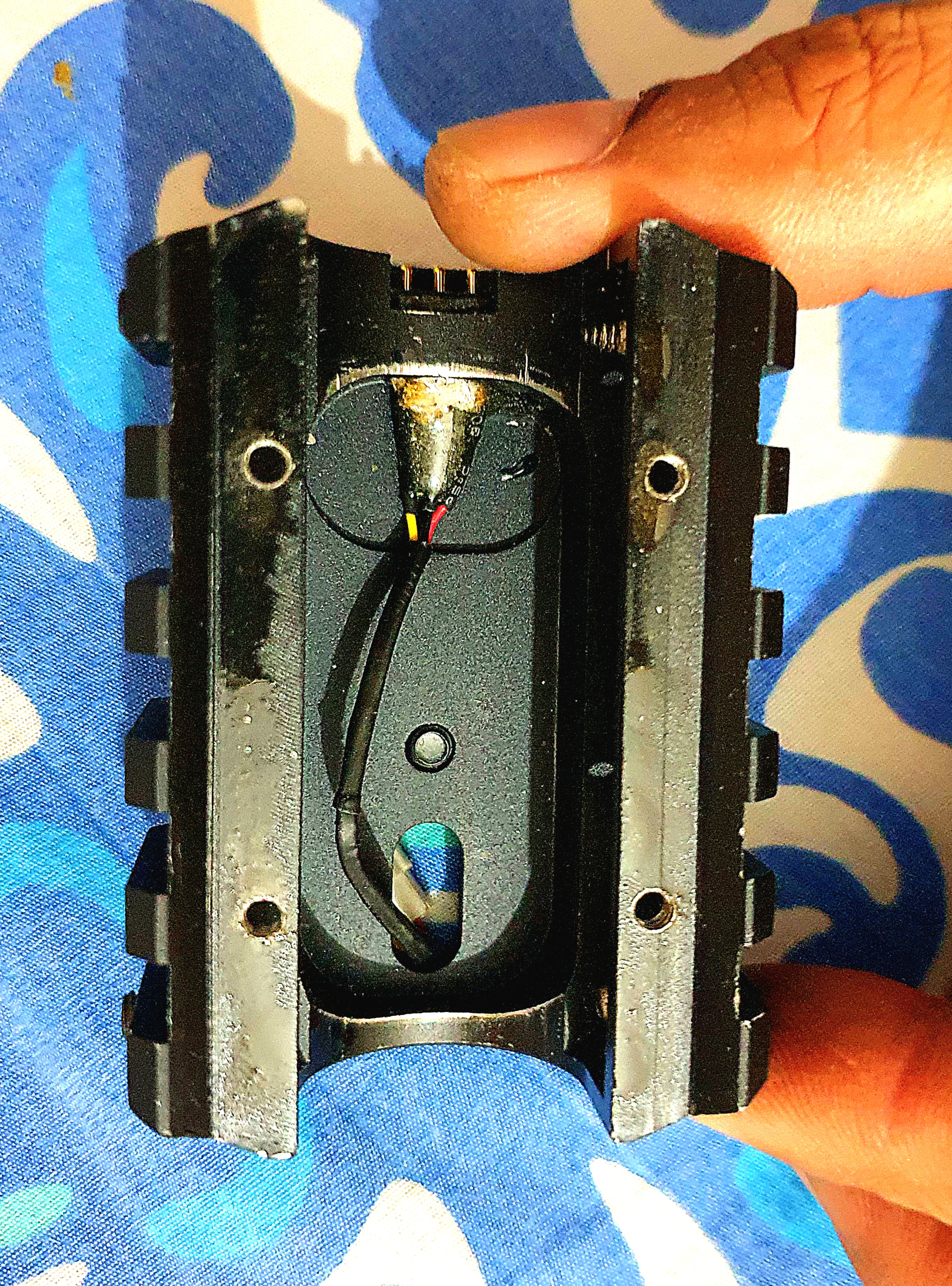

Finally made the following device to hold the barrel firmly at the point from where the barrel comes out of the action.

Such solution might help others too but it's a costly work.

Umair Bhaur

Just like FX Impact, this Daystate's barrel is also locked by one grub screw at the rear end. While only the O rings are providing support to the rest of the barrel which is not enough to hold the POI.

Finally made the following device to hold the barrel firmly at the point from where the barrel comes out of the action.

Such solution might help others too but it's a costly work.

Umair Bhaur