I am thinking about purchasing a barrel tensioning system for my Impact M3 sniper .30 . I read about the FX system increases the muzzle crack. My question is does the Huma-air or the Bullet central systems do the same thing?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel Tensioning systems for FX Impact

- Thread starter Rimshot

- Start date

You remove the shroud so I assume yes. I have seen people doing some mods to have the tension system in place, and a shroud.

Upvote 0

Any tensioning device that requires the removal of the stock shroud will make your FX bark like a hoarse Jack Russel.

That is why I opted for the Saber Tactical Top Rail.

That is why I opted for the Saber Tactical Top Rail.

Upvote 0

If noise is very important, Id say to look at the FX version and modify your factory shroud to install over the carbon fiber. This will help you get closer to the original noise level. I dont think you would be able to reuse your factory shroud on the BC/Huma kits but I could be wrong. I have a Huma kit on my 700mm 25 Cal that has been upgraded and its certainly louder, but with a good mod at the end its still pretty quiet. At some point I might look into buying a bigger diameter tube and make my own shroud to see if I can cut down on the noise even further.

Upvote 0

Thanks for the information. Something else that puzzles me depending on whos system you chose is that the more tension you apply the more your pulling on one set screw or am I missing something here. Well maybe theres another system just around the corner.

Upvote 0

Depends on the design. The FX comes with an updated clamp block that helps to secure the blued steel barrel housing in place. The Huma kit does a similar thing with the extended top rail. I chose the Huma because I like the design of the clamp a lot more than the FX version. The single set screw is certainly a design flaw imo so having more to help the housing is better. But with the BC tensioner kit, youre correct as it will pull against the rear set screw. So as you increase the tension you can pull the barrel assmebly right out of the breech.Thanks for the information. Something else that puzzles me depending on whos system you chose is that the more tension you apply the more your pulling on one set screw or am I missing something here. Well maybe theres another system just around the corner.

Upvote 0

Well I am using a FX tuning shroud with a piece of CF tube for my tension system... The same way Ernest Rowe did a while back..

I happen to find out after I setup my M3 ...on his Youtube channel.

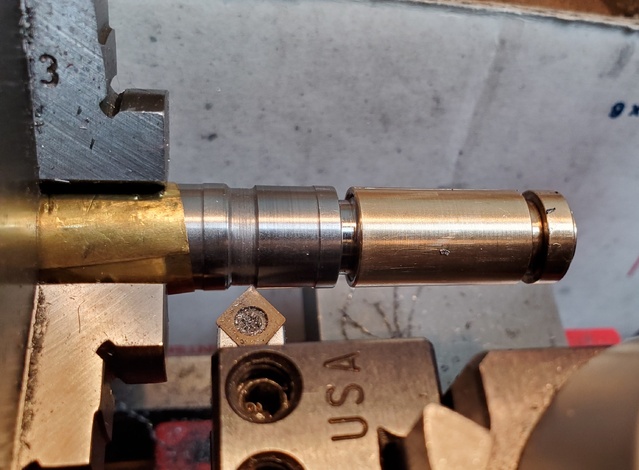

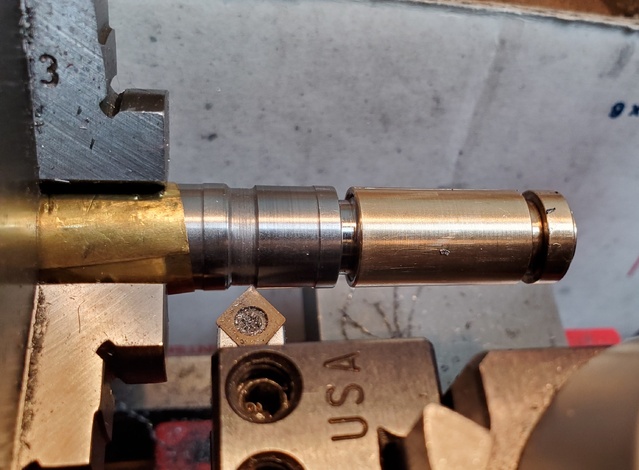

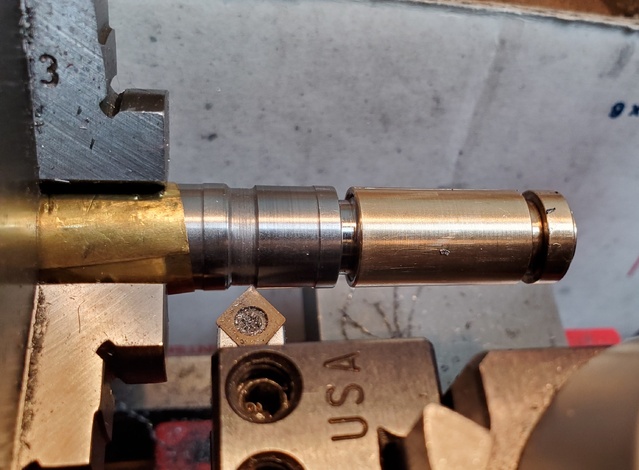

I also machined a second set screw to secure my barrel...

Then machined a groove in the barrel extension, so it would pull out.

Then I added the FX barrel clamp support for added holding power...

Btw I also use a torque wrench to get consistent tension on my Barrel.....

I happen to find out after I setup my M3 ...on his Youtube channel.

I also machined a second set screw to secure my barrel...

Then machined a groove in the barrel extension, so it would pull out.

Then I added the FX barrel clamp support for added holding power...

Btw I also use a torque wrench to get consistent tension on my Barrel.....

Upvote 0

Well I am using a FX tuning shroud with a piece of CF tube for my tension system... The same way Ernest Rowe did a while back..

I happen to find out after I setup my M3 ...on his Youtube channel.

I also machined a second set screw to secure my barrel...

Then machined a groove in the barrel extension, so it would pull out.

Then I added the FX barrel clamp support for added holding power...

Btw I also use a torque wrench to get consistent tension on my Barrel.....

It maybe better to use a torque/angle method for better consistent repeat tensioning, similar to torque to yield. (Google it) But in this case using it so the amount stretch and compression is the same each time. Proper clocking is necessary as well for repeated consistency. Especially if things are not properly square.

As I found out on my fx tension barrel as the barrel was not properly cut square and changing the impact point each time i removed the tensioning system depending on the way it was clocked.

I believe the bullet central unit is a little longer than the liner, larger like the factory original shroud(?) and designed to allow it to absorb some noise like the original shroud. But if you do buy one please install and check fitment as soon as you receive it as some were not built correctly and were too short.

It's funny as I am full circle on this and not running a tension setup at all and having better grouping and of all things with a 800mm long barrel even!

Allen

Upvote 0

I Have never a big fan of the Torque angle method...

I torque in three stages.... 20>50>85 in-lbs..

It has been giving me great results so far......on my 800mm barrel

I has been squared(both ends), recrowned and relieved the muzzle end to pass through the barrel nut!!

I torque in three stages.... 20>50>85 in-lbs..

It has been giving me great results so far......on my 800mm barrel

I has been squared(both ends), recrowned and relieved the muzzle end to pass through the barrel nut!!

Last edited:

Upvote 0

I Have never a big fan of the Torque angle method...

I toque in three stages.... 20>50>85 in-lbs..

It has been giving me great results so far......on my 800mm barrel

I has been squared(both ends), recrowned and relieved the muzzle end to pass through the barrel nut!!

With less than 10 ftlbs. That shouldn't be a issue and easily repeatable.

That's some nice looking work.

Allen

Upvote 0

I like the idea - if the thread and the hole are concentric. You have a lathe machine, mount the thread liner nut into the barrel tube - if any runout on the hole?...I has been squared(both ends), recrowned and relieved the muzzle end to pass through the barrel nut!!

I put a small radius on the liner front edge to center itself inside the nut. Also wrapping with a teflon tape to minimize if any free play.

But really like your idea I must try

Upvote 0

I currently have an Fx impact m3 800mm tensioned barrel kit and I am wondering if it’s necessary to run a carbon fiber sleeve as well as the barrel tensioner?

Upvote 0

I currently have an Fx impact m3 800mm tensioned barrel kit and I am wondering if it’s necessary to run a carbon fiber sleeve as well as the barrel tensioner?

Upvote 0

Necessary is going to be subjective person to person. But I have one on every one of my barrel assemblies to help prevent poi shifting I was experiencing before. I only have 500mm/700mm setups though. I think FX should just build/sell their rifles with the sleeve instead of the orings.I currently have an Fx impact m3 800mm tensioned barrel kit and I am wondering if it’s necessary to run a carbon fiber sleeve as well as the barrel tensioner?

Upvote 0

I find the 800 whips a lot with heavy projectiles. So yes you will need everything you can get your hands on to keep control of it.

Allen

Allen

Upvote 0

The 800 mm is a lot of barrel to keep relatively Stable... Those O-ring just don't do it for Me....

They aren't up to the task for the 700 mm!!

Since I could not find a 800 mm CF Stiffening tube....I made my own!!

So I order 2 600 mm cf tube that were on sale....

Cut one cf tube square on my lathe using a cut-off wheel

Then using the barrel as a mandrel to align the CF tubes... I super-glued them together.

They aren't up to the task for the 700 mm!!

Since I could not find a 800 mm CF Stiffening tube....I made my own!!

So I order 2 600 mm cf tube that were on sale....

Cut one cf tube square on my lathe using a cut-off wheel

Then using the barrel as a mandrel to align the CF tubes... I super-glued them together.

Upvote 0