Here's the one that started this addiction, er, obsession , uh, creative exercise:

Notes and old pics are dated October of 2016. The stock is hand molded Kydex, butt "pad" is alum and nylon risers. the wood bits helped the ergonomics for the first red dot (not shown), the 4x Gamo scope I had on it for a while and the 30 mm reddot/laser shown here. The rest of the designs carried this ergonomic mistake forward to the rest of my efforts

Current prototype:

the stock, buttpad, gripcap/mag well, upper connector, and LDC are all 3d printed. Details on that later and other posts.

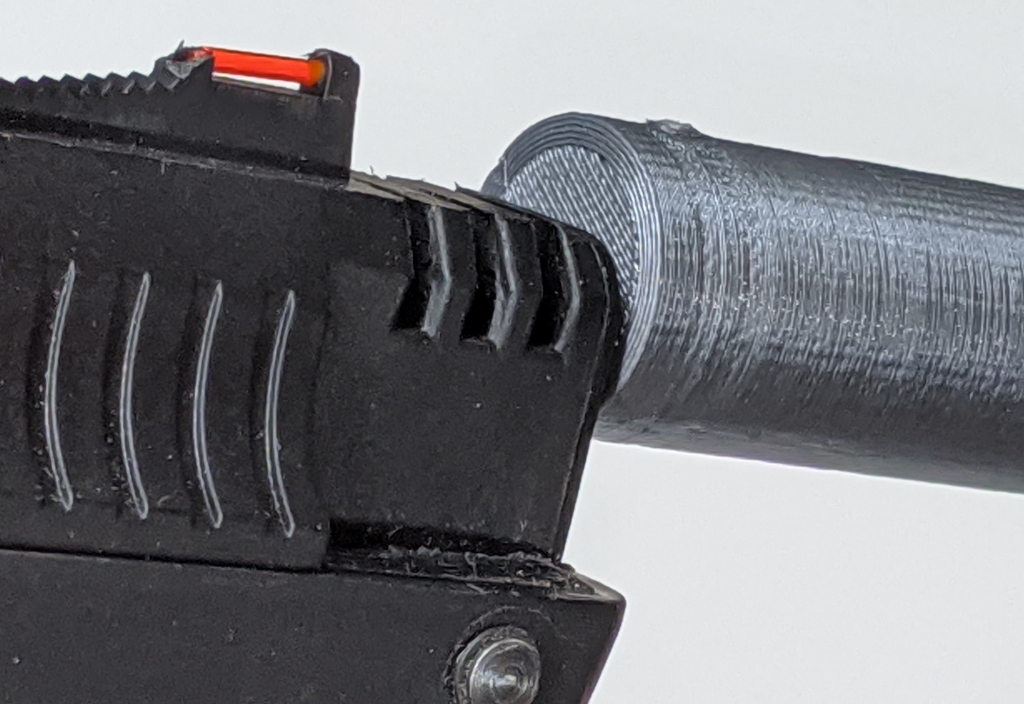

one of the things I wanted to fix from the '16 build was the sight rail. On the '16 version I ground off the top of the "upper" smooth, and glued/screwed a weaver rail. Rock solid but a ton of work. And I realize not everyone could do that mod, so I spent a lot of time figuring a way to add some hieght and do it easily and quickly. The riser rail is UTG/Leaper unit off eBay.

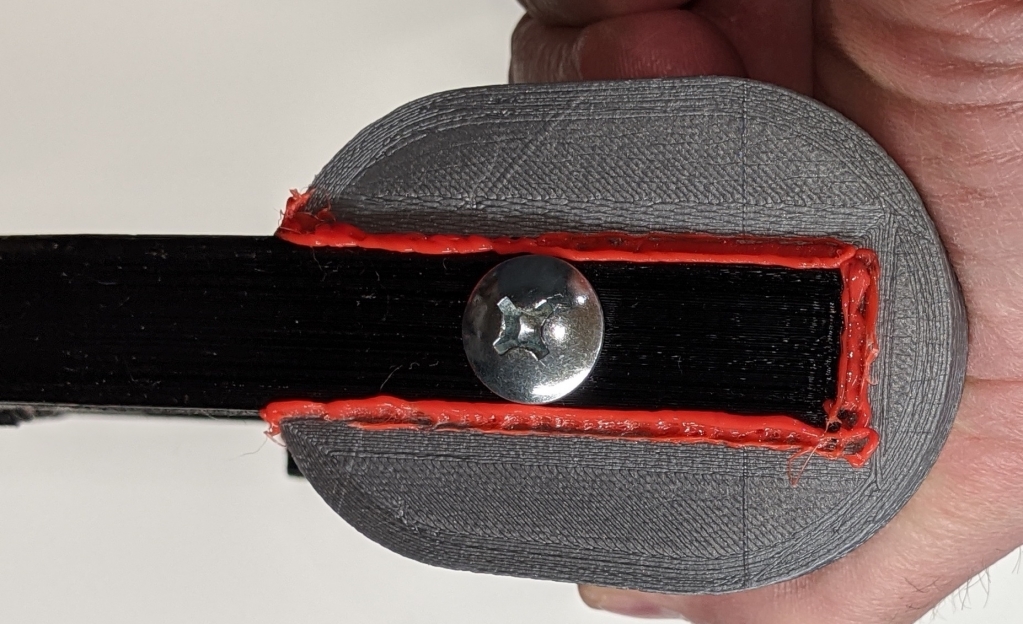

The "cheek piece" is just a bit of old mouse pad, double stick taped to the top of the stock. The "upper connector" and the butt pad are glued, Aerospace double-sided taped and the red "lines" are 3d filament I used in the 3d pen to weld the two parts together. the stock itself is PETG. Not shown (couldnt get the detail with my camera) has some "boogers" from printing. PETG is great for parts, but a pain to work with.

The rail just grabs the existing Dovetail, and adds a little height for good sight picture. sights are AR-15 foldable backup iron sights, also from ebay.

One of the issues I had designing all this was the notch for the "hammer"/latch. HAd to use two screws to allow clearance internally. PIA to get the little washers and nuts on the inside of the gun. Tweezers are your friend

The grip connection is a 8mm bolt with a flanged nut inside the grip. ITs glued down inside so you cna open the gun and not have the nut fall out, and its in place for retightening. the screw goes thru the arm of th stock and thru the grip cap, sandwiching the whole thing together for a strong connection

The LDC is eccentric, over a custom extended barrel (made by a guy who wishes to remain anonymous). the can was made to have the majority of the can ABOVE the barrel to help clearance.

front view of the can. Never noticed until its 25 times bigger than real life how stringy it looks, a better quality print is in order.

The can is 22mm x 93mm, custom sized/made to help clearance issueswitht he lower frame and the trigger guard. the barrel extends about an inch in the LDC, and uses a modified design I borrowed from the Crosman shrouds.

And this is the heart of the clearance for the ldc. I ground away enough of that area to let the back edge of the LDC clear the lower frame. Need to fill that with black marker. I used a 1/2 inch dremel sanding drum and sand paper wrapped around the printed can to shape the notch.

What have I learned? First, this gun was NEVER meant to be stocked. It kicked my butt--repeatedly-- for weeks at a time, and through several iterations. Second, I am firmly convinced that the reason we dont see many P17 stocks is that folks wnat to return the gun to its pistol format, and that some would like to use the stock as a cocking aid. I tried using the stock to help cock, but in my opinion, it doenst help to use the stock, as its an unsymmetric load and doenst help much leverage-wise.

in the near future I'll make another post with the stock built in-between the hand built version and the latest build shown here.

Notes and old pics are dated October of 2016. The stock is hand molded Kydex, butt "pad" is alum and nylon risers. the wood bits helped the ergonomics for the first red dot (not shown), the 4x Gamo scope I had on it for a while and the 30 mm reddot/laser shown here. The rest of the designs carried this ergonomic mistake forward to the rest of my efforts

Current prototype:

the stock, buttpad, gripcap/mag well, upper connector, and LDC are all 3d printed. Details on that later and other posts.

one of the things I wanted to fix from the '16 build was the sight rail. On the '16 version I ground off the top of the "upper" smooth, and glued/screwed a weaver rail. Rock solid but a ton of work. And I realize not everyone could do that mod, so I spent a lot of time figuring a way to add some hieght and do it easily and quickly. The riser rail is UTG/Leaper unit off eBay.

The "cheek piece" is just a bit of old mouse pad, double stick taped to the top of the stock. The "upper connector" and the butt pad are glued, Aerospace double-sided taped and the red "lines" are 3d filament I used in the 3d pen to weld the two parts together. the stock itself is PETG. Not shown (couldnt get the detail with my camera) has some "boogers" from printing. PETG is great for parts, but a pain to work with.

The rail just grabs the existing Dovetail, and adds a little height for good sight picture. sights are AR-15 foldable backup iron sights, also from ebay.

One of the issues I had designing all this was the notch for the "hammer"/latch. HAd to use two screws to allow clearance internally. PIA to get the little washers and nuts on the inside of the gun. Tweezers are your friend

The grip connection is a 8mm bolt with a flanged nut inside the grip. ITs glued down inside so you cna open the gun and not have the nut fall out, and its in place for retightening. the screw goes thru the arm of th stock and thru the grip cap, sandwiching the whole thing together for a strong connection

The LDC is eccentric, over a custom extended barrel (made by a guy who wishes to remain anonymous). the can was made to have the majority of the can ABOVE the barrel to help clearance.

front view of the can. Never noticed until its 25 times bigger than real life how stringy it looks, a better quality print is in order.

The can is 22mm x 93mm, custom sized/made to help clearance issueswitht he lower frame and the trigger guard. the barrel extends about an inch in the LDC, and uses a modified design I borrowed from the Crosman shrouds.

And this is the heart of the clearance for the ldc. I ground away enough of that area to let the back edge of the LDC clear the lower frame. Need to fill that with black marker. I used a 1/2 inch dremel sanding drum and sand paper wrapped around the printed can to shape the notch.

What have I learned? First, this gun was NEVER meant to be stocked. It kicked my butt--repeatedly-- for weeks at a time, and through several iterations. Second, I am firmly convinced that the reason we dont see many P17 stocks is that folks wnat to return the gun to its pistol format, and that some would like to use the stock as a cocking aid. I tried using the stock to help cock, but in my opinion, it doenst help to use the stock, as its an unsymmetric load and doenst help much leverage-wise.

in the near future I'll make another post with the stock built in-between the hand built version and the latest build shown here.