A friend asked me to see if I could improve the trigger on his recently acquired Concept XR.

Here is the disassembly video. I'm not a YouTuber, nor am I aspiring to be one. No fancy editing. It's just a simple video that can hopefully help someone.

https://www.youtube.com/watch?v=VfapAuWrvSA&t=4s

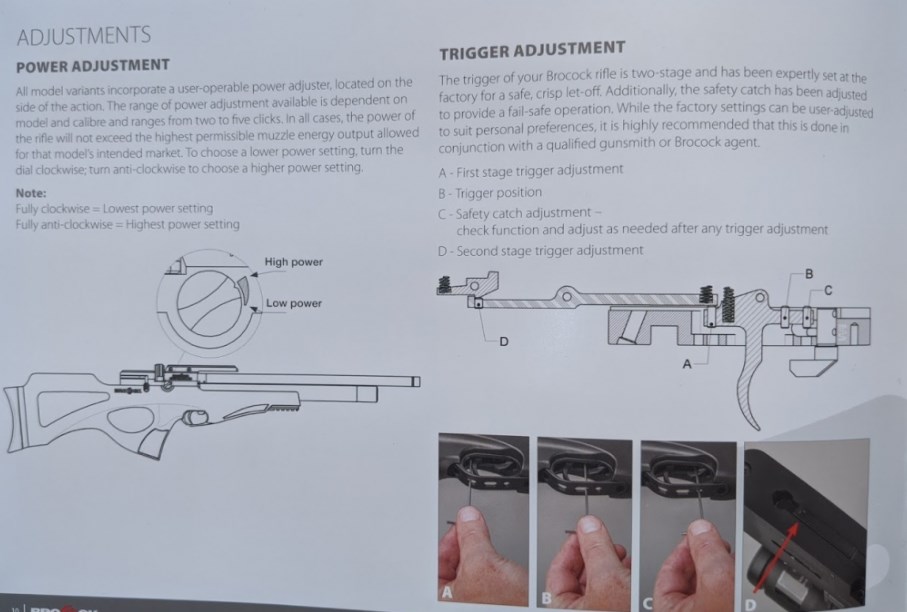

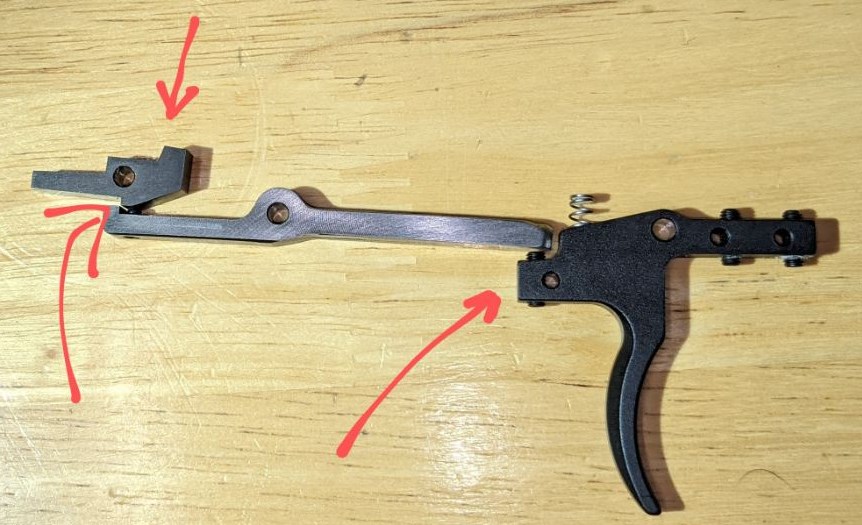

There are really three main areas that need polished to make the Concept's trigger feel much better, basically the three points of contact between the various trigger components.

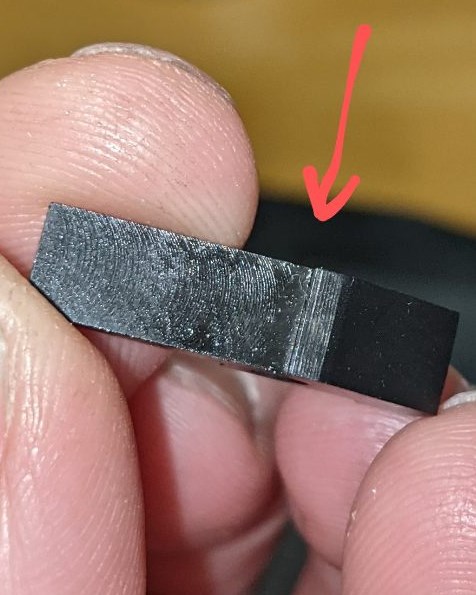

The parts come with some machining marks in them, and I personally think those machining marks not smoothly sliding past each other is where some of "scratchy" feel comes from. Here's an example of the contact point right next to screw "D" before I did any polishing...

Those machining lines can't be doing anything good towards a smooth trigger with a clean break, especially b/c they're parallel on each part, so they can nest inside each other to create a skipping/catchy sensation.

Here's a photo about halfway through polishing them out....

The bluing is leaving, as are the ridges. Eventually I arrived at a smooth surface on this and the other contact points.

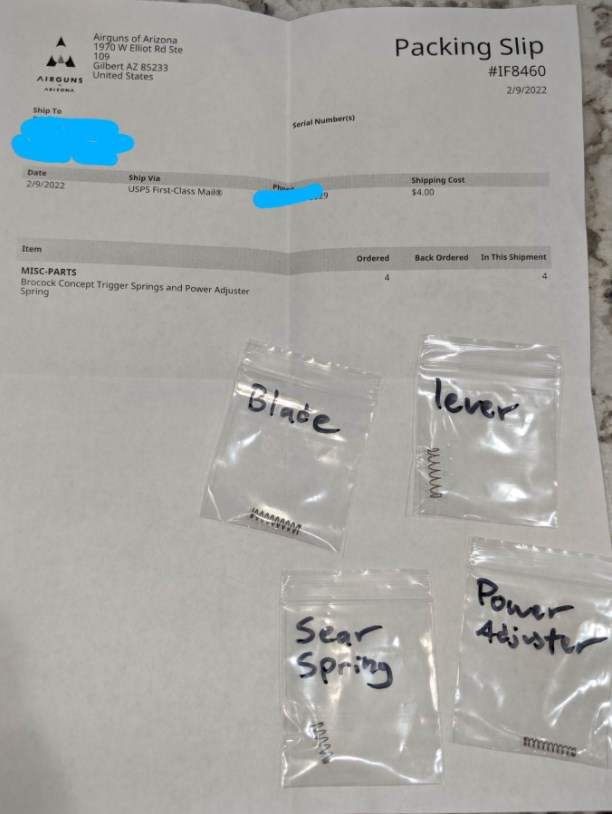

Since the previous owner had cut coils off all 3 springs in the trigger and the spring that controls the power wheel, Dan reached out to AOA and they came through big time. Not only did they have OEM replacements, but they mailed them to me all labeled up. Made the job much easier.

I used no power tools, just polishing stones to get the machining ridges gone, and then 500 and then 1200 grit wet/dry sandpaper for the polishing. No angles were changed, nor were large amounts of metal removed.

Slight dabs of moly paste on each polished point.

Slight dabs of grease in the bottom of the spring pockets (to aid in keeping the springs where they should be until all the parts were back together).

Slight dabs of blue loktite on each of the trigger adjustment screws to hopefully make the trigger adjustments stay where they are.

It's breaking at 13 or 14 ounces now, MUCH more crisp. The design doesn't allow for a couple ounce trigger, but can be made to feel MUCH better with a little attention and care.

Here is the disassembly video. I'm not a YouTuber, nor am I aspiring to be one. No fancy editing. It's just a simple video that can hopefully help someone.

https://www.youtube.com/watch?v=VfapAuWrvSA&t=4s

There are really three main areas that need polished to make the Concept's trigger feel much better, basically the three points of contact between the various trigger components.

The parts come with some machining marks in them, and I personally think those machining marks not smoothly sliding past each other is where some of "scratchy" feel comes from. Here's an example of the contact point right next to screw "D" before I did any polishing...

Those machining lines can't be doing anything good towards a smooth trigger with a clean break, especially b/c they're parallel on each part, so they can nest inside each other to create a skipping/catchy sensation.

Here's a photo about halfway through polishing them out....

The bluing is leaving, as are the ridges. Eventually I arrived at a smooth surface on this and the other contact points.

Since the previous owner had cut coils off all 3 springs in the trigger and the spring that controls the power wheel, Dan reached out to AOA and they came through big time. Not only did they have OEM replacements, but they mailed them to me all labeled up. Made the job much easier.

I used no power tools, just polishing stones to get the machining ridges gone, and then 500 and then 1200 grit wet/dry sandpaper for the polishing. No angles were changed, nor were large amounts of metal removed.

Slight dabs of moly paste on each polished point.

Slight dabs of grease in the bottom of the spring pockets (to aid in keeping the springs where they should be until all the parts were back together).

Slight dabs of blue loktite on each of the trigger adjustment screws to hopefully make the trigger adjustments stay where they are.

It's breaking at 13 or 14 ounces now, MUCH more crisp. The design doesn't allow for a couple ounce trigger, but can be made to feel MUCH better with a little attention and care.