Preface - it's insane how a relatively minor modification can completely change the feel of a rifle! ..

was bummed out last Thursday at the range when I realized that something was VERY wrong with my FX Maverick. Spent the first part of my session testing out the slow twist poly LW in my new "BlingVet" build on a 100y bench, and afterwards I decided that it was time to check the Mav ahead of my NRL22 match on Saturday morning.

So I uncased the rifle and shot it a couple of times to re-zero the windage (gusty day). It was shooting lights out as usual with the (unsorted, unwashed, unlubed) 44gr JSBs (big holes are from the Mav)..

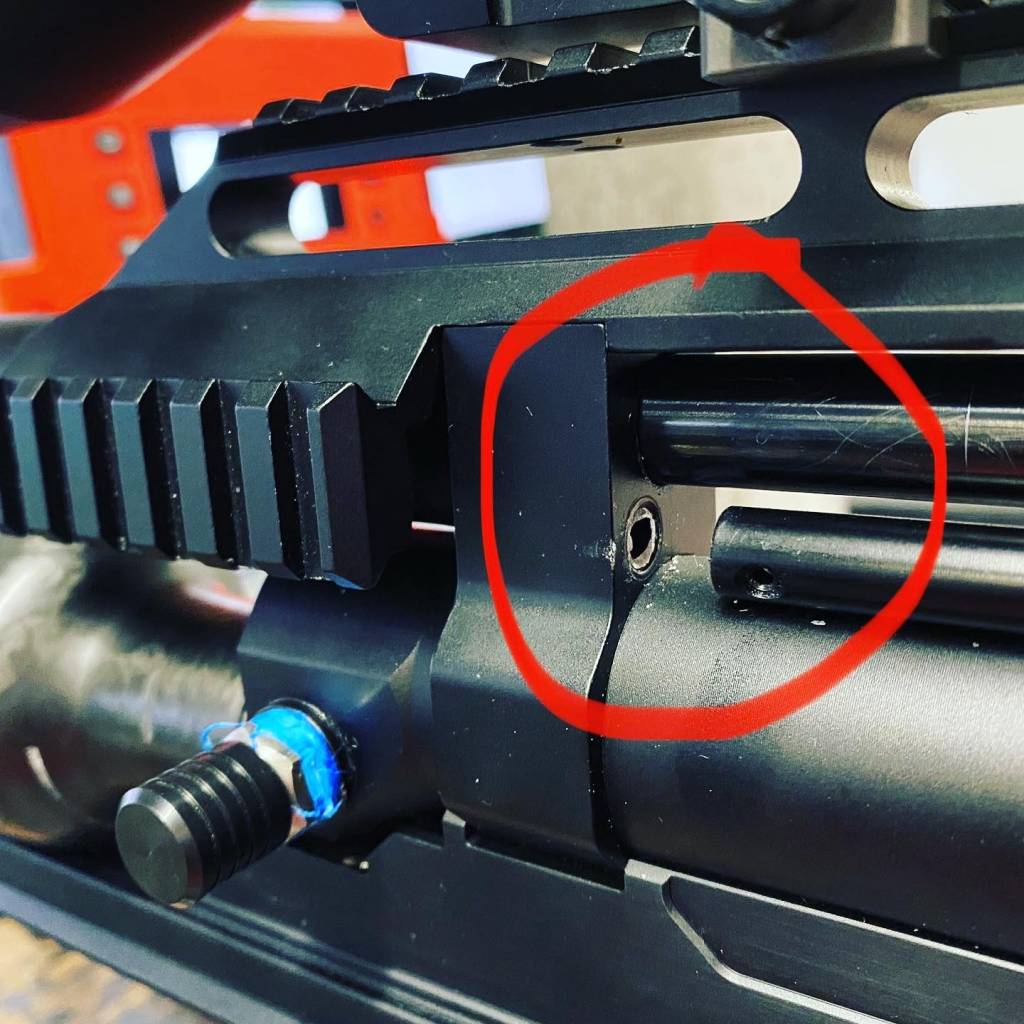

Out of nowhere, the feel of the cocking action changed for the worse! The rifle was still shooting accurately, so I knew that it wasn't likely the hammer system. Cycled the lever back, and boom - I see the problem clear as day:

My "reloding rod guide" (art. #19511) failed catastrophically. At this point, I knew my rifle would be out of commission for NRL22, but I already had plans to swap out the first reg housing with a replacement given to me by support for a separate issue.

Newman was prompt in responding to my issue (the man is a true superhero!). He offered to send me the replacement component on Monday, but I had some ideas floating in my mind for improving this component and my impatience got the better of me.

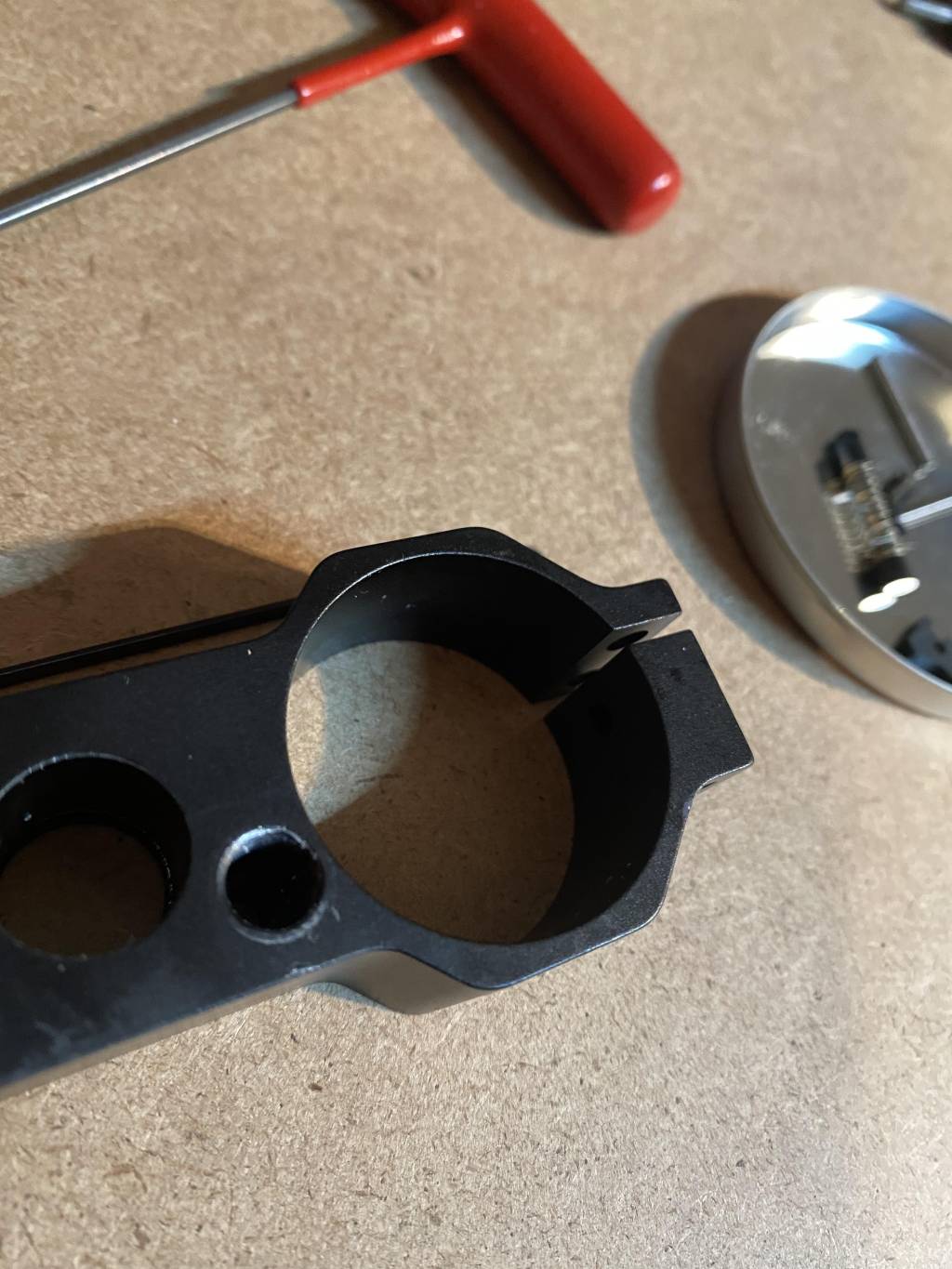

So what I decided to do was fabricate the reloading rod guide replacement in 316 stainless. With some effort, I was able to extract the broken threaded section of the rod guide out of the front support housing:

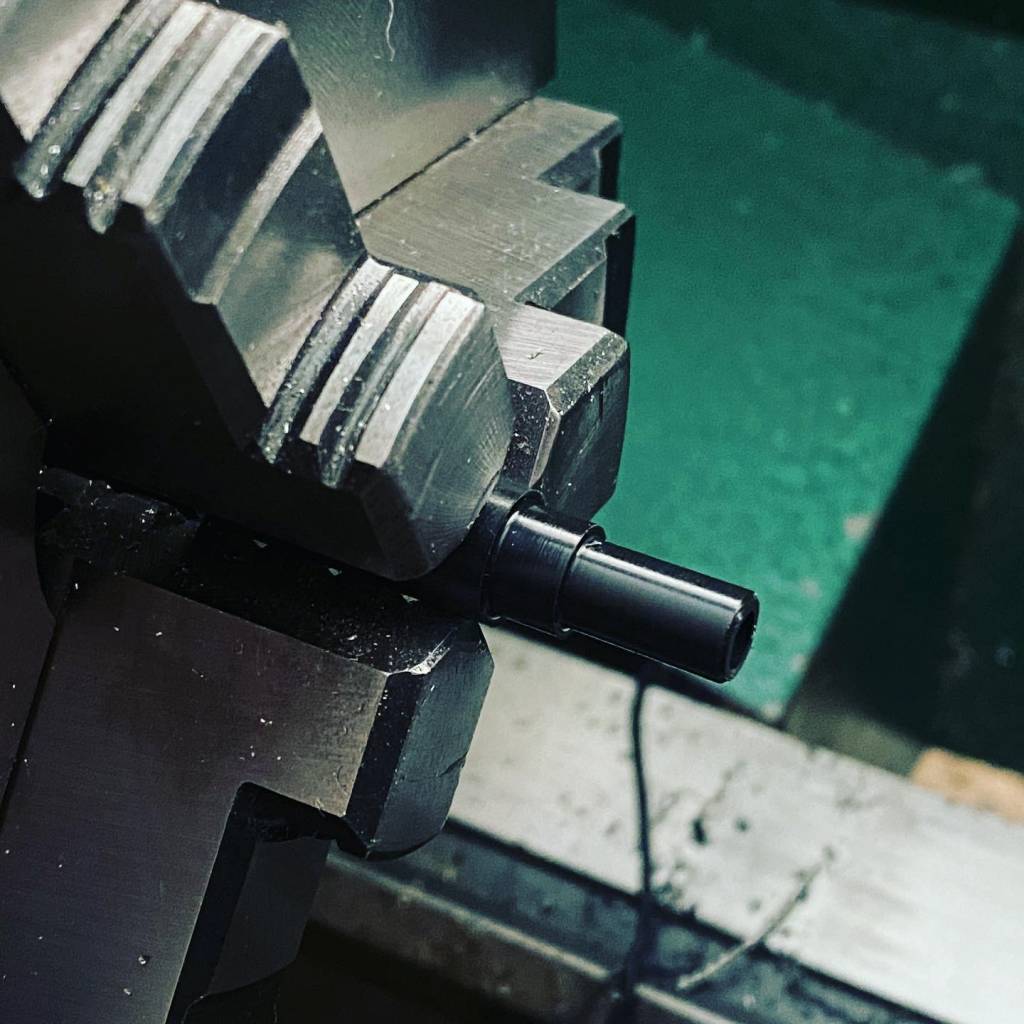

I had the idea of making an internal thread (6x1mm) in the broken rod guide, but the thread in the housing is an 8x1mm thread, and I wasn't real motivated to make a small part like that with dual-threads:

With the rifle torn down, I examined the factory reloading rod (mic'd at 3.978mm). The rod was bent to hell - being the likely cause of my failure. I wasn't thrilled at the idea of straightening it back out and re-using it, so I parked the idea and focussed on sketching out a stronger replacement rod guide in my mind.

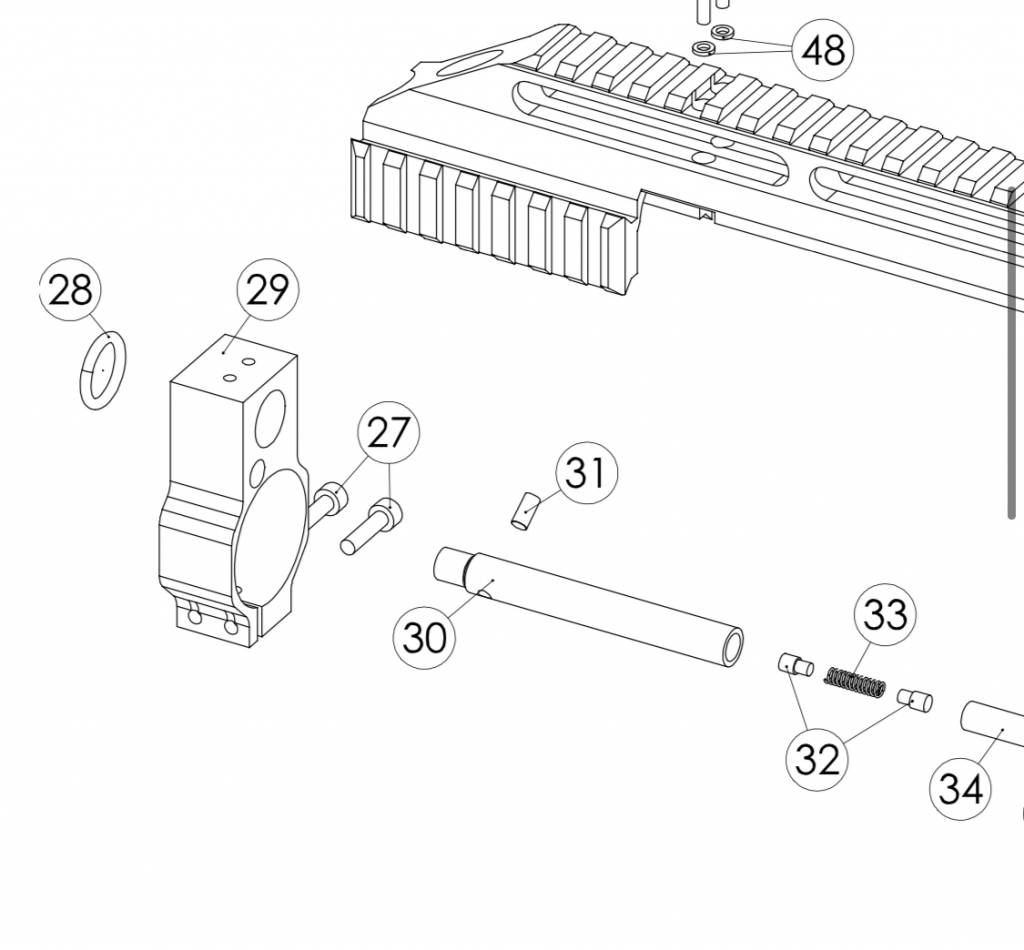

The Maverick diagram had a few parts internal to the rod guide. There's the spring-loaded component that assists in keeping the lever in closed and that is kept in place by a rod guide bushing (34 in the schematic):

I also realized that the hollow threaded end of my stainless part would need another seat / stopper for the spring mechanism, and I decided to use Delrin 150 for those parts (press fit).

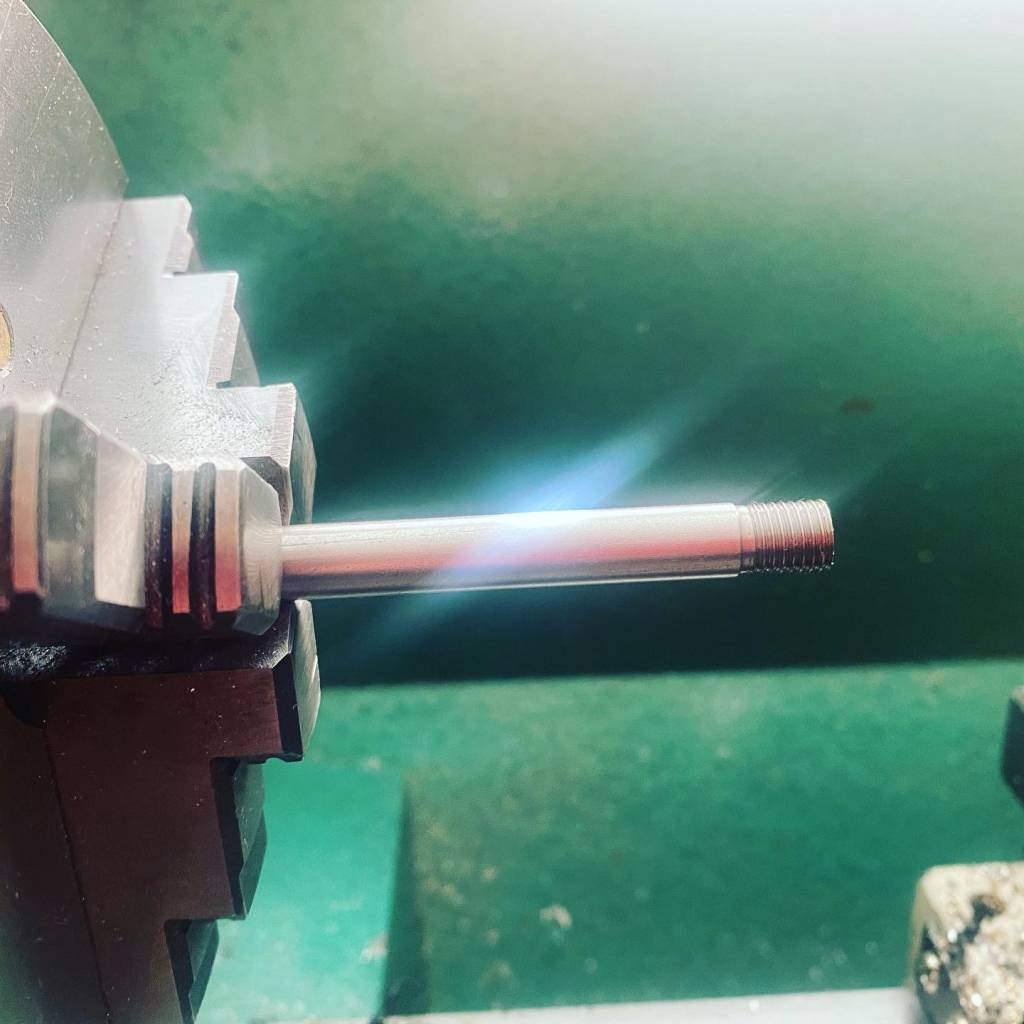

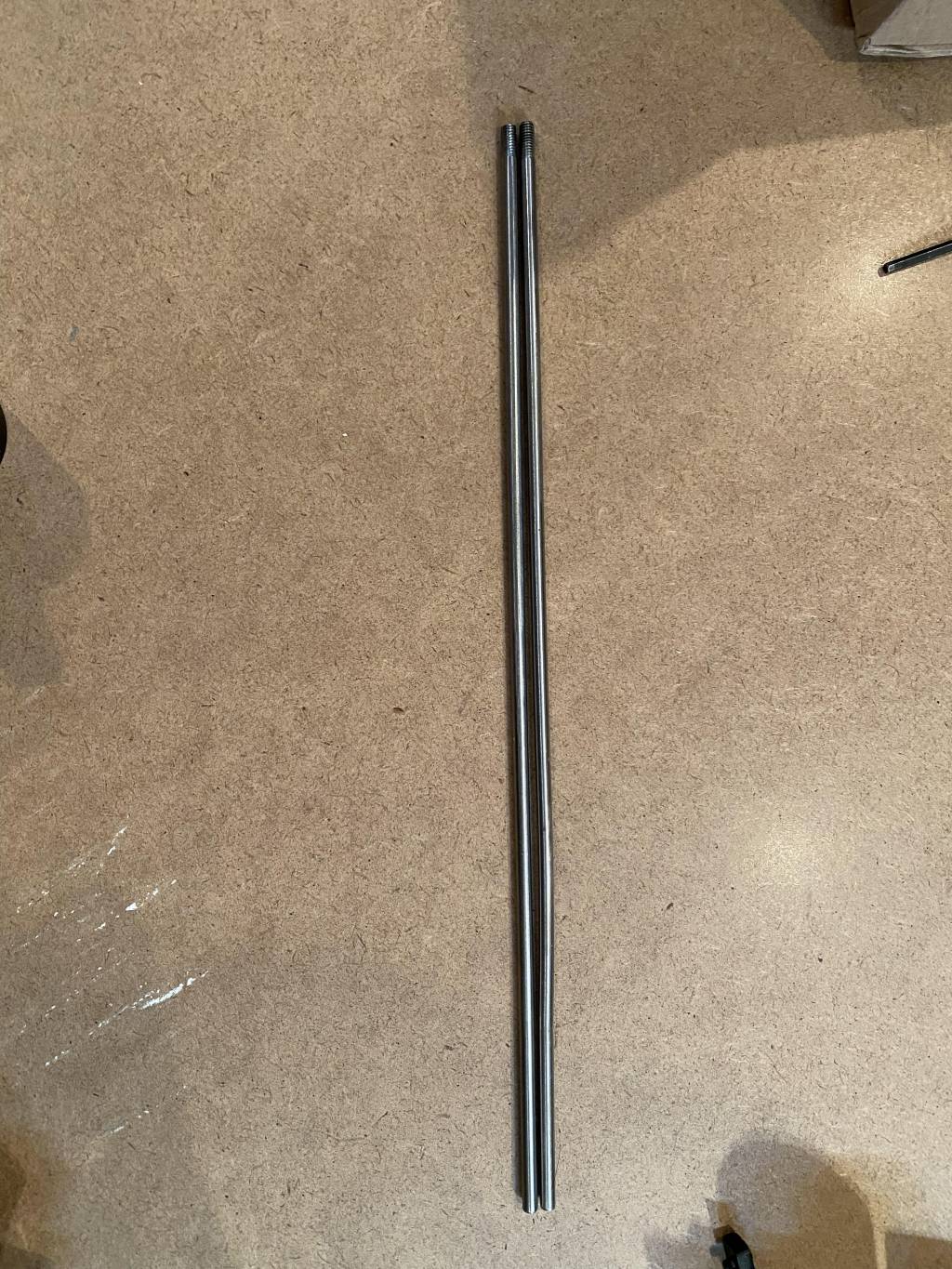

Now for that rod! Knew that I wouldn't be able to source a good 4mm stainless rod on a Sunday. Knew that I had some 5/32" music wire in hand though. I mic'd it out and it was a little larger than 4mm OD. Turning & threading music wire is a real NIGHTMARE! Rockwell hardness of C50 for the stock I had on hand. Nonetheless, I knew that it would be MUCH stronger than most stainless and decided to use it. Left is my music wire rod and the factory rod on the right (and that was AFTER my brief attempt at straightening it)..

Staging the workpieces..

End to end..

This new rod is VERY snug in the rifle, but not so snug (unlubed) that it would bind up. I lubed it with a high-quality synthetic motor oil though, and when I finally got everything back together - it feels like and ENTIRELY new rifle!!!!!!!

I cannot fully describe how the cocking action feels on this rifle now, but it feels "luxurious". It used to have quite a bit of slop and felt loosey goosey. My lever would pop open on its own with momentum of the rifle, but now it feels more like the EVOL did when the HST was set extremely light. It's very smooth now, and I can feel every single ounce of spring compression when cycling it back!

was bummed out last Thursday at the range when I realized that something was VERY wrong with my FX Maverick. Spent the first part of my session testing out the slow twist poly LW in my new "BlingVet" build on a 100y bench, and afterwards I decided that it was time to check the Mav ahead of my NRL22 match on Saturday morning.

So I uncased the rifle and shot it a couple of times to re-zero the windage (gusty day). It was shooting lights out as usual with the (unsorted, unwashed, unlubed) 44gr JSBs (big holes are from the Mav)..

Out of nowhere, the feel of the cocking action changed for the worse! The rifle was still shooting accurately, so I knew that it wasn't likely the hammer system. Cycled the lever back, and boom - I see the problem clear as day:

My "reloding rod guide" (art. #19511) failed catastrophically. At this point, I knew my rifle would be out of commission for NRL22, but I already had plans to swap out the first reg housing with a replacement given to me by support for a separate issue.

Newman was prompt in responding to my issue (the man is a true superhero!). He offered to send me the replacement component on Monday, but I had some ideas floating in my mind for improving this component and my impatience got the better of me.

So what I decided to do was fabricate the reloading rod guide replacement in 316 stainless. With some effort, I was able to extract the broken threaded section of the rod guide out of the front support housing:

I had the idea of making an internal thread (6x1mm) in the broken rod guide, but the thread in the housing is an 8x1mm thread, and I wasn't real motivated to make a small part like that with dual-threads:

With the rifle torn down, I examined the factory reloading rod (mic'd at 3.978mm). The rod was bent to hell - being the likely cause of my failure. I wasn't thrilled at the idea of straightening it back out and re-using it, so I parked the idea and focussed on sketching out a stronger replacement rod guide in my mind.

The Maverick diagram had a few parts internal to the rod guide. There's the spring-loaded component that assists in keeping the lever in closed and that is kept in place by a rod guide bushing (34 in the schematic):

I also realized that the hollow threaded end of my stainless part would need another seat / stopper for the spring mechanism, and I decided to use Delrin 150 for those parts (press fit).

Now for that rod! Knew that I wouldn't be able to source a good 4mm stainless rod on a Sunday. Knew that I had some 5/32" music wire in hand though. I mic'd it out and it was a little larger than 4mm OD. Turning & threading music wire is a real NIGHTMARE! Rockwell hardness of C50 for the stock I had on hand. Nonetheless, I knew that it would be MUCH stronger than most stainless and decided to use it. Left is my music wire rod and the factory rod on the right (and that was AFTER my brief attempt at straightening it)..

Staging the workpieces..

End to end..

This new rod is VERY snug in the rifle, but not so snug (unlubed) that it would bind up. I lubed it with a high-quality synthetic motor oil though, and when I finally got everything back together - it feels like and ENTIRELY new rifle!!!!!!!

I cannot fully describe how the cocking action feels on this rifle now, but it feels "luxurious". It used to have quite a bit of slop and felt loosey goosey. My lever would pop open on its own with momentum of the rifle, but now it feels more like the EVOL did when the HST was set extremely light. It's very smooth now, and I can feel every single ounce of spring compression when cycling it back!