Edit:

In the following pages you can find info about this compressors, oil type, failures and new developments. Share your experience and let us know!

--------

By far I am not an expert, but I have a YH compressor for a year now with no problems (well, a few ones all fixable). So Here are a few tips that I have learned so far, and please you are more than welcome to add more or correct others or ask if you have doubts. I will add more tips here if you add more.

1- How Long should I run it?: Do not run the compressor for more than 25/30 min in order to avoid overheating (not only for the compressor, also to avoid too much oil and water vapors), remember, water and oil can find the way to your air reservoir, build up and make a mess!. (note: Overheating is the problem, so 25/30 min is just a reference could be more or less depending on the temp)

2- Do I need Filters?: Use filters, the bigger the better, 2 if you can (the gold ones), one for oil, one for water...filters always vertical. do not trust the small OEM filter. Ideal setup: compressor, long hpa hose in water (condensation prior filters like this one or larger https://www.ebay.com/itm/6000psi-Paintball-PCP-DN2-40-Mircrobore-Hose-for-Fill-Station-Charging-Adaptor/302764753865), filter 1 oil, filter 2 water, bottle.

3- What Oil?, this is confusing: Use PAO 46 Oil, Hydraulic ISO 46/68 or 100 (several brands Royal Purple among others), the last ones stink less, SAE30 Non Detergent is the same than ISO 100 (works too, just another way to name it) search for oil for Breathing Air or Scuba Compressors. Change oil more often (I change every 5 hours of total use, that is every 10 fills of 30 minutes)). Do not overfill with oil your compressor. Do not use motor oil, you can use temporarily 100% Synthetic oil like 5w-30 or 5w-40 but is a mistake in general (will work but then you need to purge all the oil out with gas oil or something like that before add the correct compressor oil). Motor oil creates ashes ...

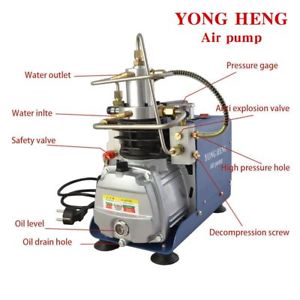

4- While Running do I have to do something?: YES! Purge the oil and water out of the compressor every 5 minutes or so, while running, IS VERY IMPORTANT. This means that you need to open the screw (the opposite side of the decompression screw, not mentioned in the pic) for a few seconds every 5 minutes or so. You will see how much water and oil goes out. (And do not get into your tank). Good compressors (expensive ones) do this with a solenoid valve and you can program it on and off every x minutes. So nothing new, you need to do this manually. IS A MUST.

5- What about temperature? Keep the water / refrigerant cold, the colder the better. Note: there is not thermostat , is a simple thermometer that measure the temp of the head (do not use it loose inside the cahe, there is a hole in the second stage piston, where the probes go, those are very cheap, very easy to find: "digital thermometer aquarium" in case you need replacement. Like this one: https://www.ebay.com/itm/D2BF-Digital-LCD-Aquarium-Thermometer-Temperature-Meter-With-Waterproof-Probe-To/264104206096 the pump that comes with the compressor is enough to cool it down, more flow will not improve the cooling process (ice will). Try to keep level the water pump and the compressor in order to have a constant and smooth water flow. (That last tip by @cosmic)

Do not let temperature goes over 70 celsius, if it does is better turn it off and coolit. Suggestion: Grab 2 1/2 gal (2 liter) plastic bottles ad water and freeze them, use in the bucket so you can keep temp down, water temp without ice can go up easy 35 to 40 celsius. With 2 ice bottles, usually the YH temperature do not exceed the 55°C

6- At start, should I close everything? What I do is: I connect everything, close decompression screw and purge screw on the compressor, open the bottle (try to fill the bottle when it have less than 3000psi/200bar over that is harder for the compressor but you can push it to 250 bar, no more than that or you can ruin the compressor), once pressure is equal in the bottle and compressor I open the purge screw, I turn on the compressor and for the first minute or so, leave the purge knob open. This will help inicial condensation get out of the system faster. Then I close it and open it for a few seconds every 5 minutes or so.

Others use check valves, and do not open the tank until pressure equalizes

7- I turn it off, but I want to fill it a bit more: Do not exceed the 310 bar. Do not turn off around 280-300 bar and try to turn it on later, the piston will not start (or might start but requires much more force to start and that will impact the longevity too much wear) unless you use a check valve. I have never had a problem starting at 250 bar and below. Over that you can turn it on and the piston will not move (inicial start have too much pressure) and you can bust your compressor.

8- What about spare parts: If you can, get 2 compressors...just in case (come on! they are cheap!), spare parts can be found on amazon, ebay or aliexpress

9- What about vibration?: (added by @Sonny) A nice padded rubber floor mat(1/4 inch) also helps with the vibration of the unit keeps it from walking across the floor too. Check bolts periodically that vibration make the loose easy, specially new compressors!

10- Does it worth it?: For me, absolutely! simple math: 6.8L tank fill from 200 bar to 300 bar cost around US$10 bucks per fill. YH Compresor US$300, so you need 40 fills to pay for the compressor, electric bill and oil, over that, you are winning. I use mine once a week, for 1 year that is 52 weeks, that is US$520 winning already, but most important: Knowledge!. I have learn a lot about compressors and now I value more the high end ones...like with airguns, I start with a Marauder...and now I have an impact x, the marauder teach me a LOT!

Few problems that I have had

1- I turn it on and nothing happens

Fix: I took the cap out and find that one conector got unplugged, plug it again and set.

2- Suddenly it start to loose air the compressor while it was almost at 300 bar

Fix: Check explosion proof disc sometimes it blows away before 4500/300 bar get more of those (cheap)

I had blown 2 o 4 finally I add 2 and no more problems (not the best solution but it worked). Those are made to burst @ 5000 psi but sometimes they got broken with less and that sucks! so I add 2 and I am extra careful checking, besides I have the pressure set version, doble check there. Anyway in the spare parts that come with the compressor they include a few, but always good to have more..if you need them and you do not have it you are stuck.

https://www.youtube.com/watch?v=OypA2kWvI74

Note: Video does not belong to me

3- Pump electric inlet in the compressor is getting off: Loctite

4- Filter lose air: So far the weaker point on my setup are filter seals, but easy to fix with o'rings. Find a good base and wrench unscrew the filter caps once they have been under hpa is a pain.

5- Plug it in with the power button on: that lead to a lot of problems, check page 3.

6- After 1.4 years stop working...piston fails totally! replacement cost about US$25 (check page 3)

More to come ...

I do not know if this is a good or bad compressor, really do not care! for me it works and just want to share my experience, probably there are better compressors out there.

Hope more experienced users can post here too...a bit of help is always welcome!

Hope this help others to start with compressors like YH, and this is not "the way" to do it, you can do it like this and still have failures, just good practices. I think YH compressors are a great way to start and will give some users more freedom, and they will buy better compressors later, so It helps the whole industry.

PS: English is not my main language, sorry for my written mistakes

(pcp´s I have, MROD, PROD, IMPACTX all good and dry)

Note: This tips are made mainly for compressor to SCBA tank, taking at least 10 minutes to fill or more. Direct to airguns is way faster and some tips will not apply.

In the following pages you can find info about this compressors, oil type, failures and new developments. Share your experience and let us know!

--------

By far I am not an expert, but I have a YH compressor for a year now with no problems (well, a few ones all fixable). So Here are a few tips that I have learned so far, and please you are more than welcome to add more or correct others or ask if you have doubts. I will add more tips here if you add more.

1- How Long should I run it?: Do not run the compressor for more than 25/30 min in order to avoid overheating (not only for the compressor, also to avoid too much oil and water vapors), remember, water and oil can find the way to your air reservoir, build up and make a mess!. (note: Overheating is the problem, so 25/30 min is just a reference could be more or less depending on the temp)

2- Do I need Filters?: Use filters, the bigger the better, 2 if you can (the gold ones), one for oil, one for water...filters always vertical. do not trust the small OEM filter. Ideal setup: compressor, long hpa hose in water (condensation prior filters like this one or larger https://www.ebay.com/itm/6000psi-Paintball-PCP-DN2-40-Mircrobore-Hose-for-Fill-Station-Charging-Adaptor/302764753865), filter 1 oil, filter 2 water, bottle.

3- What Oil?, this is confusing: Use PAO 46 Oil, Hydraulic ISO 46/68 or 100 (several brands Royal Purple among others), the last ones stink less, SAE30 Non Detergent is the same than ISO 100 (works too, just another way to name it) search for oil for Breathing Air or Scuba Compressors. Change oil more often (I change every 5 hours of total use, that is every 10 fills of 30 minutes)). Do not overfill with oil your compressor. Do not use motor oil, you can use temporarily 100% Synthetic oil like 5w-30 or 5w-40 but is a mistake in general (will work but then you need to purge all the oil out with gas oil or something like that before add the correct compressor oil). Motor oil creates ashes ...

4- While Running do I have to do something?: YES! Purge the oil and water out of the compressor every 5 minutes or so, while running, IS VERY IMPORTANT. This means that you need to open the screw (the opposite side of the decompression screw, not mentioned in the pic) for a few seconds every 5 minutes or so. You will see how much water and oil goes out. (And do not get into your tank). Good compressors (expensive ones) do this with a solenoid valve and you can program it on and off every x minutes. So nothing new, you need to do this manually. IS A MUST.

5- What about temperature? Keep the water / refrigerant cold, the colder the better. Note: there is not thermostat , is a simple thermometer that measure the temp of the head (do not use it loose inside the cahe, there is a hole in the second stage piston, where the probes go, those are very cheap, very easy to find: "digital thermometer aquarium" in case you need replacement. Like this one: https://www.ebay.com/itm/D2BF-Digital-LCD-Aquarium-Thermometer-Temperature-Meter-With-Waterproof-Probe-To/264104206096 the pump that comes with the compressor is enough to cool it down, more flow will not improve the cooling process (ice will). Try to keep level the water pump and the compressor in order to have a constant and smooth water flow. (That last tip by @cosmic)

Do not let temperature goes over 70 celsius, if it does is better turn it off and coolit. Suggestion: Grab 2 1/2 gal (2 liter) plastic bottles ad water and freeze them, use in the bucket so you can keep temp down, water temp without ice can go up easy 35 to 40 celsius. With 2 ice bottles, usually the YH temperature do not exceed the 55°C

6- At start, should I close everything? What I do is: I connect everything, close decompression screw and purge screw on the compressor, open the bottle (try to fill the bottle when it have less than 3000psi/200bar over that is harder for the compressor but you can push it to 250 bar, no more than that or you can ruin the compressor), once pressure is equal in the bottle and compressor I open the purge screw, I turn on the compressor and for the first minute or so, leave the purge knob open. This will help inicial condensation get out of the system faster. Then I close it and open it for a few seconds every 5 minutes or so.

Others use check valves, and do not open the tank until pressure equalizes

7- I turn it off, but I want to fill it a bit more: Do not exceed the 310 bar. Do not turn off around 280-300 bar and try to turn it on later, the piston will not start (or might start but requires much more force to start and that will impact the longevity too much wear) unless you use a check valve. I have never had a problem starting at 250 bar and below. Over that you can turn it on and the piston will not move (inicial start have too much pressure) and you can bust your compressor.

8- What about spare parts: If you can, get 2 compressors...just in case (come on! they are cheap!), spare parts can be found on amazon, ebay or aliexpress

9- What about vibration?: (added by @Sonny) A nice padded rubber floor mat(1/4 inch) also helps with the vibration of the unit keeps it from walking across the floor too. Check bolts periodically that vibration make the loose easy, specially new compressors!

10- Does it worth it?: For me, absolutely! simple math: 6.8L tank fill from 200 bar to 300 bar cost around US$10 bucks per fill. YH Compresor US$300, so you need 40 fills to pay for the compressor, electric bill and oil, over that, you are winning. I use mine once a week, for 1 year that is 52 weeks, that is US$520 winning already, but most important: Knowledge!. I have learn a lot about compressors and now I value more the high end ones...like with airguns, I start with a Marauder...and now I have an impact x, the marauder teach me a LOT!

Few problems that I have had

1- I turn it on and nothing happens

Fix: I took the cap out and find that one conector got unplugged, plug it again and set.

2- Suddenly it start to loose air the compressor while it was almost at 300 bar

Fix: Check explosion proof disc sometimes it blows away before 4500/300 bar get more of those (cheap)

I had blown 2 o 4 finally I add 2 and no more problems (not the best solution but it worked). Those are made to burst @ 5000 psi but sometimes they got broken with less and that sucks! so I add 2 and I am extra careful checking, besides I have the pressure set version, doble check there. Anyway in the spare parts that come with the compressor they include a few, but always good to have more..if you need them and you do not have it you are stuck.

https://www.youtube.com/watch?v=OypA2kWvI74

Note: Video does not belong to me

3- Pump electric inlet in the compressor is getting off: Loctite

4- Filter lose air: So far the weaker point on my setup are filter seals, but easy to fix with o'rings. Find a good base and wrench unscrew the filter caps once they have been under hpa is a pain.

5- Plug it in with the power button on: that lead to a lot of problems, check page 3.

6- After 1.4 years stop working...piston fails totally! replacement cost about US$25 (check page 3)

More to come ...

I do not know if this is a good or bad compressor, really do not care! for me it works and just want to share my experience, probably there are better compressors out there.

Hope more experienced users can post here too...a bit of help is always welcome!

Hope this help others to start with compressors like YH, and this is not "the way" to do it, you can do it like this and still have failures, just good practices. I think YH compressors are a great way to start and will give some users more freedom, and they will buy better compressors later, so It helps the whole industry.

PS: English is not my main language, sorry for my written mistakes

(pcp´s I have, MROD, PROD, IMPACTX all good and dry)

Note: This tips are made mainly for compressor to SCBA tank, taking at least 10 minutes to fill or more. Direct to airguns is way faster and some tips will not apply.