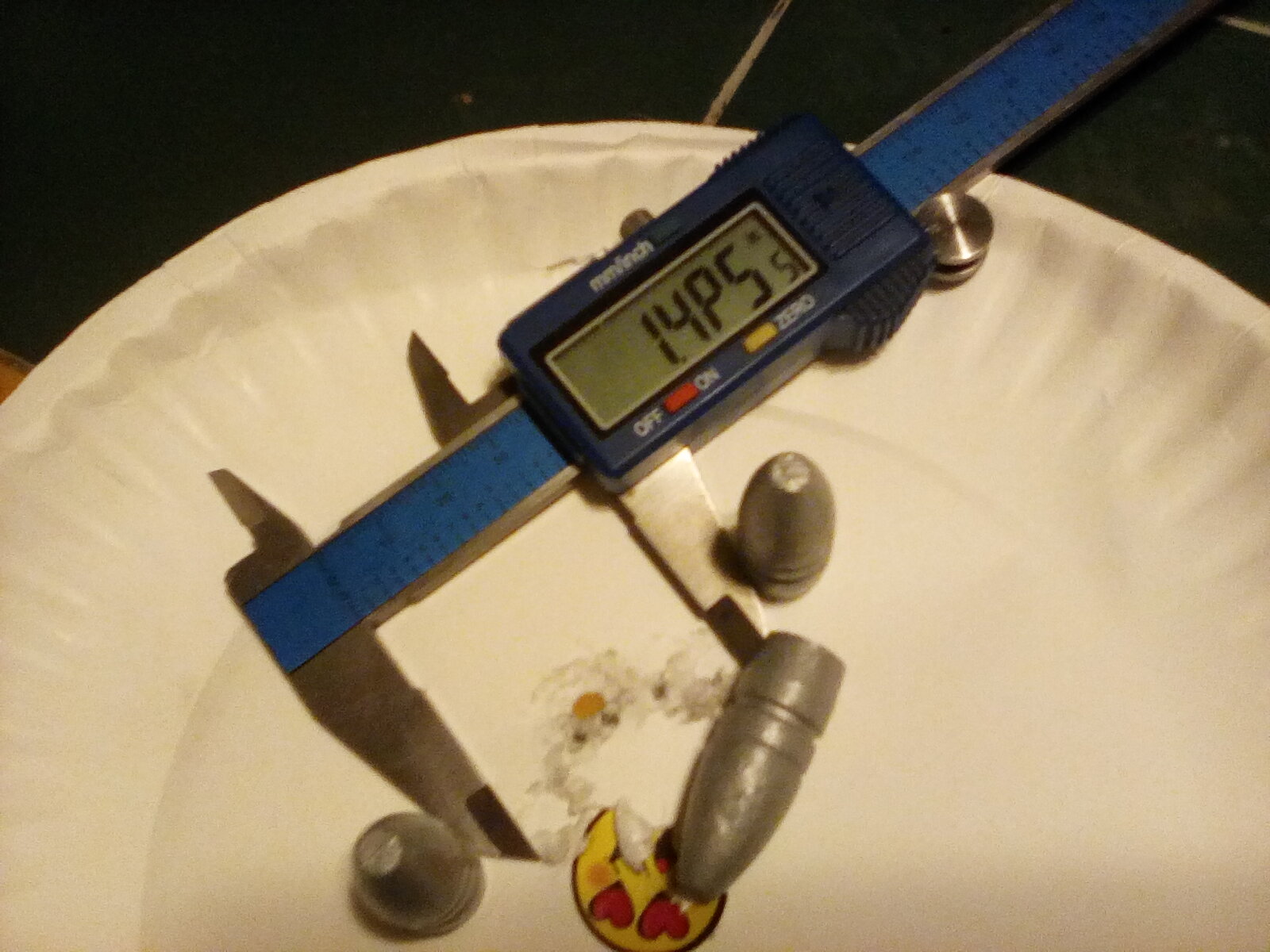

I wanted a place to post some groups from our cast slugs....It's been a long and hard journey getting my Texan consistently accurate.. I'm so happy with my NOE 460 grain gas check mold...Barrel hand lapped...Slugs Powder coated pure lead...rem oil for lube.....50 yards...3shots..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

N/A Cast Slug Groups!!!!

- Thread starter RM.510bigbore

- Start date

Love to hear your journey since I know casting your own is a long and painful one. How did you end up with 460gr. NOE mold?

I ended up buying this NOE mold during the pandemic... I wasn't sure about the gas check...but I figured it would reduce bearing surface.. Also price for.me is a consideration... So I think $110.00 for 5 cavity mold.. The hard part of my experience has been fixing the fatal flaws of 800 foot pound platform.... My .510 LW barrel was horrible.... It was so bad it would shear small chunks of lead that would go in the action....Break everything.... Lol At first casting was rough until I got lead thermometer and a PID controller for my Lee4-20 lead.pot...Also a.hot plate to warm your molds a.must.....I also have a accurate molds that is very good also....Price a bit more than NOE.... This 460 grain slug runs around a 2.5 B.C....This is truthfully the most recoil I can handle out of platform.... Accurate molds 650 Spire.Point Boat tail equally accurate at .5 B.C but recoil.is brutal.... I can't let unexpired shooters use or will get scoped....I bought the lead at local junk yard for $1.00 a pound...sheets of pure roofing lead.....

Upvote 0

This is the path I choose too, but I bought a lot of molds in case a particular design doesn't work out. Questioned gas check molds too, but decided it's worth the risk (At least for Lee molds anyway). Do you mind sharing the URL of the mold you purchased?

Upvote 0

Thank you for the confirmation. It's always good to know what molds are proven performers.Yes that's it...

What did you do to the gun to shoot such tight groups? Or did you get extremely lucky and the gun simply loved the round?

Truthful the most important step was actually hand lead lapping the bore..My barrel was bad...Haven't seen many any worse. Next thing than might be helping is a full carbon fiber sleeve over the barrel in tension.. My sleeve is full one inch diameter to the bushing,, .250 thick...So solid...I keep two end screws for cap tight..Donny FL is super tight keeping everything in tension... I also glued Cf liner to barrel...might not of been nessary.. Powder coating and lube with a now smooth and uniform barrel with actual strength and stiffness are helping accuracy to get more consistent.. I also made a stock that attaches to the frame by clamping not threaded into aluminum to strip out from recoil..Thank you for the confirmation. It's always good to know what molds are proven performers.

What did you do to the gun to shoot such tight groups? Or did you get extremely lucky and the gun simply loved the round?

Attachments

Upvote 0

Here's 5 shots 50 yards. With Accurate Molds 650 grain Spire Point Boat Tail ...This is hard wheel weight lead powder coated with a touch of rem oil for lube. Shooting off external regulator.. Velocity around 750 fps. Shooting 3 shots groups much easier... Wow the 650,s really consume a lot of air....Maybe 10-15 shots off 30 minute SCBA tank till off regulator...4300 psi to 3625 psi......I have big 90 min 5500 psi SCBA tank...took heavy... Too gimped.to move....

Upvote 0