I’d had issues with older manometers sticking and not reading accurate pressure in the reservoir and plenum. I was informed that AAA no longer uses the older style gauges. After reaching out to Tom Costan about the issue I received updated manometers and instructions on how to replace them.

Below are the original older manometers.

During last night’s thunderstorm I decided to do this overdue maintenance work on my Evol. For the longest time I’d been apprehensive about changing anything about the gun. I’m over it. Once I removed the receiver (as well as the attached barrel and reservoir all in one piece) from the chasis it felt like I was in some of my other rifles.

But I can say that I am impressed by the build quality and materials used. Anyhow, after following the schematics on the AAA website it wasn’t too hard to figure out what to do. When I couldn’t see where a bolt needed to be removed I figured it out when I encountered it. So if you’re not mechanically inclined, but can work a screw driver and set of Allen keys you should be ok here. BUT you will benefit greatly from having a tool made specifically for removing the gauges from this gun. To remove the plenum manometer, you must separate the receiver from the chasis.

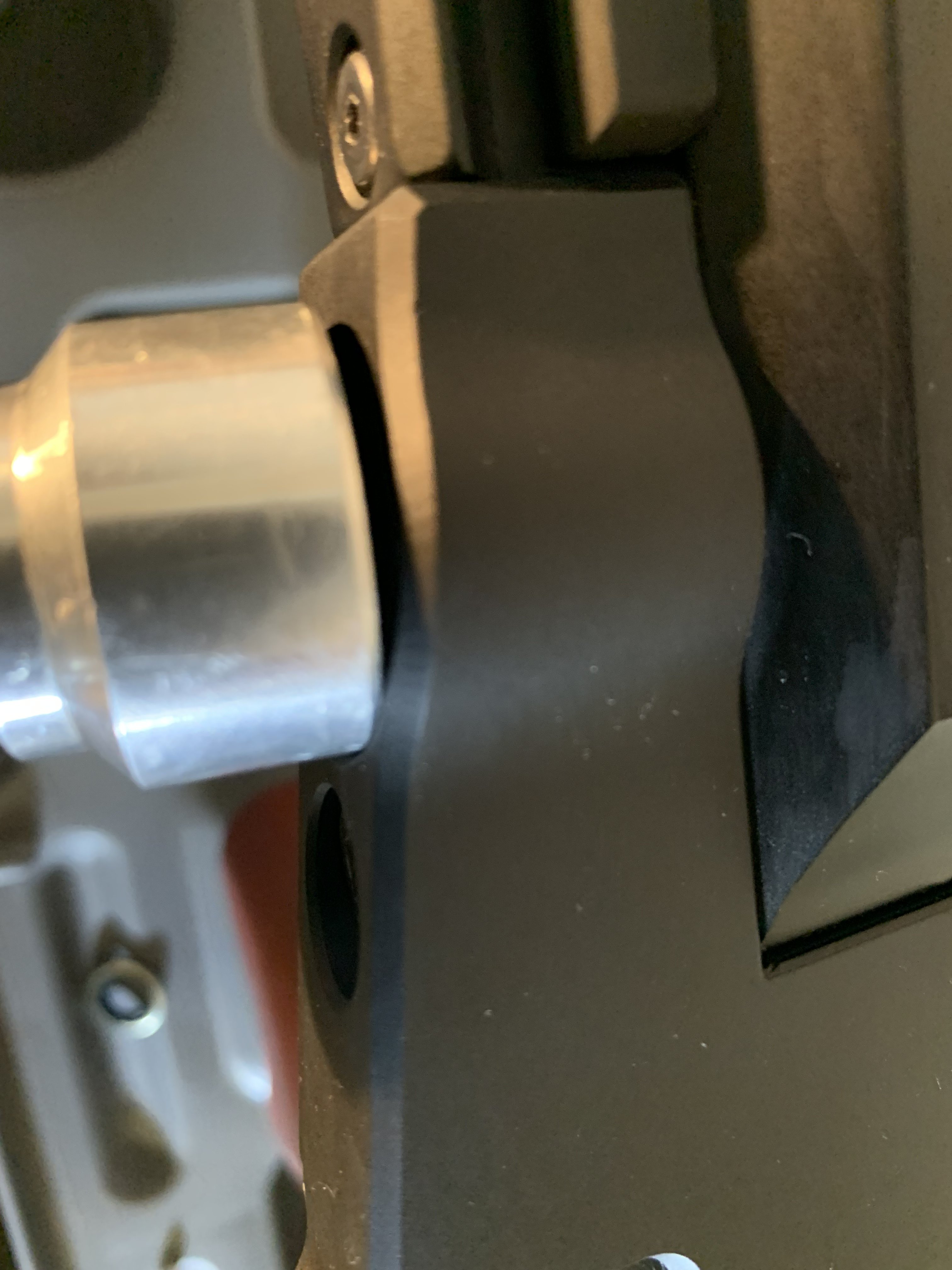

This is why. The diameter of the gauge tool is about as wide as the opening in the chasis. The tool pictured on the ratchet is similar to the purple Evol gauge tool. To separate the receiver from the chasis I removed the large ¼” hex bolt (on the right), a smaller allen screw on the pic rail towards the moderator, and the allen screw that runs through the safety switch (I used two Allen keys of the same size to remove the safety).

Here’s a view of the back of the old and new manometer. I cleaned up the threads and slightly greased the o-rings before installing the new manometer.

Below are photos of the newer manometers

After installing the new ones I gassed up the reservoir before fitting it back into the chasis. I’ve learned that doing this saves time if you have to revisit an area that would otherwise be covered up or inaccessible once reassembled. That’s exactly what occurred. It appears that the o-ring came unseated when I inverted the gauge seal (the only only thing holding the o-ring in place is silicone grease) and pinched it when I screwed down the manometer. At least this is my suspicion. It was not screwed down tight at all. As a result of pinching the o-ring, at around 1600 psi I heard hissing then a *pop* like a half-empty old balloon stepped on by a bored child. I closed my tank valve and tried to tighten the manometer a little but the hissing didn’t stop completely. I allowed the air to vent from the reservoir through the plenum before completely removing this plenum manometer. When I removed it this is what I saw.

Now I have to hunt down the correct sized o-ring because I don’t have a 1.5 x 10.5 mm o-ring anywhere that I can find. May as well make a list and stock up on several o-rings needed for various parts and guns.

Below are the original older manometers.

During last night’s thunderstorm I decided to do this overdue maintenance work on my Evol. For the longest time I’d been apprehensive about changing anything about the gun. I’m over it. Once I removed the receiver (as well as the attached barrel and reservoir all in one piece) from the chasis it felt like I was in some of my other rifles.

But I can say that I am impressed by the build quality and materials used. Anyhow, after following the schematics on the AAA website it wasn’t too hard to figure out what to do. When I couldn’t see where a bolt needed to be removed I figured it out when I encountered it. So if you’re not mechanically inclined, but can work a screw driver and set of Allen keys you should be ok here. BUT you will benefit greatly from having a tool made specifically for removing the gauges from this gun. To remove the plenum manometer, you must separate the receiver from the chasis.

This is why. The diameter of the gauge tool is about as wide as the opening in the chasis. The tool pictured on the ratchet is similar to the purple Evol gauge tool. To separate the receiver from the chasis I removed the large ¼” hex bolt (on the right), a smaller allen screw on the pic rail towards the moderator, and the allen screw that runs through the safety switch (I used two Allen keys of the same size to remove the safety).

Here’s a view of the back of the old and new manometer. I cleaned up the threads and slightly greased the o-rings before installing the new manometer.

Below are photos of the newer manometers

After installing the new ones I gassed up the reservoir before fitting it back into the chasis. I’ve learned that doing this saves time if you have to revisit an area that would otherwise be covered up or inaccessible once reassembled. That’s exactly what occurred. It appears that the o-ring came unseated when I inverted the gauge seal (the only only thing holding the o-ring in place is silicone grease) and pinched it when I screwed down the manometer. At least this is my suspicion. It was not screwed down tight at all. As a result of pinching the o-ring, at around 1600 psi I heard hissing then a *pop* like a half-empty old balloon stepped on by a bored child. I closed my tank valve and tried to tighten the manometer a little but the hissing didn’t stop completely. I allowed the air to vent from the reservoir through the plenum before completely removing this plenum manometer. When I removed it this is what I saw.

Now I have to hunt down the correct sized o-ring because I don’t have a 1.5 x 10.5 mm o-ring anywhere that I can find. May as well make a list and stock up on several o-rings needed for various parts and guns.

Last edited: