You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diana Diana 54

- Thread starter beerthief

- Start date

That’s a good one. So is this.

www.tapatalk.com

www.tapatalk.com

The Dianawerk Collective-Detailed Step-by-Step 48-52-54 Tuning Instructions

RWS 48-52-54 - Disassembly/Reassembly, Replacing Springs, Guides & Seals - Step by Step How to Do It (this is very long!) I first wrote this sever

Upvote 0

I'm not a professional, please use common sense, a spring compressor and proper PPE. You may have to make a block that allows you to compress the rear of receiver (trigger assembly) without touching the safety lever. Also I type really slow and a response or two have posted since I started. They most likely know more than I, and this may be used mostly for entertainment purposes only

Haven't pulled the stock off my 54 yet, but had plans to tomorrow (or the day after). I know there are some washers (steel & synthetic) that the "sledge" system relies on, which have to go in a certain order of top/bottom, of the two(?) bolting points. I have to look that part up to confirm, will post back with certainty if no one else replies before then. But...

After that it's fairly straightforward as any Diana. The rear cap around safety is plastic, remove that as not to damage (pops off). Two pins in rear of receiver retain the trigger assembly, knock those out (place in shorter dummy pins if you have them), remove the trigger assembly (straight back), remove spring, replace spring, replace trigger assembly (make sure trigger pins are about center and you didn't lose any), line up receiver and trigger assembly holes, replace pins**

**If you didn't use dummy pins there's a high probability that a part of a spring that looks like a bit of thin wire is blocking one of the holes, DO NOT just try and smash your retaining pin through, it will break that spring. You have to find a way to press it down from one side and somewhat as gently as possible tap your pin into place from the other**

Don't forget to pop the plastic end cap back on, fiddle with your washers, bolts & stock. Done.

Haven't pulled the stock off my 54 yet, but had plans to tomorrow (or the day after). I know there are some washers (steel & synthetic) that the "sledge" system relies on, which have to go in a certain order of top/bottom, of the two(?) bolting points. I have to look that part up to confirm, will post back with certainty if no one else replies before then. But...

After that it's fairly straightforward as any Diana. The rear cap around safety is plastic, remove that as not to damage (pops off). Two pins in rear of receiver retain the trigger assembly, knock those out (place in shorter dummy pins if you have them), remove the trigger assembly (straight back), remove spring, replace spring, replace trigger assembly (make sure trigger pins are about center and you didn't lose any), line up receiver and trigger assembly holes, replace pins**

**If you didn't use dummy pins there's a high probability that a part of a spring that looks like a bit of thin wire is blocking one of the holes, DO NOT just try and smash your retaining pin through, it will break that spring. You have to find a way to press it down from one side and somewhat as gently as possible tap your pin into place from the other**

Don't forget to pop the plastic end cap back on, fiddle with your washers, bolts & stock. Done.

Last edited:

Upvote 0

Rear cap on D54/56 doesn’t come off. Depending on your spring compressor you might need to make an adapter to sit under the plastic “shelf” where the safety slide sits. If it’s stock power plant you’ll have considerably more pre-load than the 2mm in Tinbum video LOL. Use a compressor, it’s a stout spring. For anyone taking a 54/56 apart for the first time, cell phone pics are invaluable. If you really want to understand how to make one sing find the articles by Nitrocrushr. Tremendous amount of adjustability built into these guns.

Upvote 0

cjtamu, Thank you for that bit of information. I'm familiar with the 34, 350 and 460 family of Diana airguns and their disassembly. If using the Air Venturi rail lock spring compressor, I can say it's possible to mangle up that end cap of the other Diana's a little if not careful under certain conditions...

Upvote 0

That gun is challenging to put back together with a Rail Lock because the elevation doesn’t match well with where you need to push. Look at it when you take it out and be sure you make the adapter big enough that you can have it level when you push. Actually used a pipe clamp on mine in the end because it matched up better.

Upvote 0

Think i will send it off , i could manage it but just do not want to . Thanks for all the replies , pictures and video .

Thanks again

also i would like it tuned down to around 10 FPE

Thanks again

also i would like it tuned down to around 10 FPE

Last edited:

Upvote 0

Sending your gun out might be a good idea, especially if not comfortable getting into it.

Figured I'd post some of my experience I've had today. Flipped the gun over so bottom side was facing up. Removed the two bolts holding stock on, one furthest foreword, and one an inch or so from trigger guard. Two sets of washer stacks for the sledge system can be found within, on mine it was (front) steel, synthetic, steel and (rear) steel, synthetic (no third?). Removing side lever came next, fairly straight foreword.

There wasn't a ton of spring preload, maybe 2.5" inches give or take, but was under some tension... The rest was all basically what i typed previously (except that plastic end cap isn't removeable ). Until it come time to replace that (bleep) sidelever... The tension was all out of whack, the rear lever spacer washers are nearly impossible to get in there... Well, that's about it. But it's enough to raise your blood pressure if you're not calm. Took a bit to figure out, but now that I did, I know and really not too complicated.

). Until it come time to replace that (bleep) sidelever... The tension was all out of whack, the rear lever spacer washers are nearly impossible to get in there... Well, that's about it. But it's enough to raise your blood pressure if you're not calm. Took a bit to figure out, but now that I did, I know and really not too complicated.

Figured I'd post some of my experience I've had today. Flipped the gun over so bottom side was facing up. Removed the two bolts holding stock on, one furthest foreword, and one an inch or so from trigger guard. Two sets of washer stacks for the sledge system can be found within, on mine it was (front) steel, synthetic, steel and (rear) steel, synthetic (no third?). Removing side lever came next, fairly straight foreword.

There wasn't a ton of spring preload, maybe 2.5" inches give or take, but was under some tension... The rest was all basically what i typed previously (except that plastic end cap isn't removeable

Upvote 0

Sending your gun out might be a good idea, especially if not comfortable getting into it.

Figured I'd post some of my experience I've had today. Flipped the gun over so bottom side was facing up. Removed the two bolts holding stock on, one furthest foreword, and one an inch or so from trigger guard. Two sets of washer stacks for the sledge system can be found within, on mine it was (front) steel, synthetic, steel and (rear) steel, synthetic (no third?). Removing side lever came next, fairly straight foreword.

There wasn't a ton of spring preload, maybe 2.5" inches give or take, but was under some tension... The rest was all basically what i typed previously (except that plastic end cap isn't removeable). Until it come time to replace that (bleep) sidelever... The tension was all out of whack, the rear lever spacer washers are nearly impossible to get in there... Well, that's about it. But it's enough to raise your blood pressure if you're not calm. Took a bit to figure out, but now that I did, I know and really not too complicated.

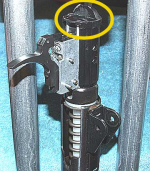

Is this the plastic cap your referring to?

Upvote 0

Yes, that's the one. Don't know official terms..

My best guess, since the entire action of the 54 "floats" back and forth during the shot cycle, they had to keep it in place.

My best guess, since the entire action of the 54 "floats" back and forth during the shot cycle, they had to keep it in place.

Upvote 0

LoL.. well it's in my terminology I guess .. just wanted to be sure on that .Yes, that's the one. Don't know official terms..

So far it looks like more or less be mindful of the washers and there orientation ?

Upvote 0

That and possibly having to set the tension of the side lever when it closes/returns to foreword position. Really, getting the side lever pivot washers/shims into place was absolutely the worst part for me.LoL.. well it's in my terminology I guess .. just wanted to be sure on that .

So far it looks like more or less be mindful of the washers and there orientation ?

Upvote 0

Just got to hold your mouth just right and thell go...lolThat and possibly having to set the tension of the side lever when it closes/returns to foreword position. Really, getting the side lever pivot washers/shims into place was absolutely the worst part for me.

One more thing I forgot above

The trigger block just stays in that " cap" part and no worries of it falling put or apart to cause more work ? Looks like it all stays together as a unit ? So it's mostly pop the 2 pins out and back off the compressor ?

I guess I need to look over that cocking lever adjustment as well ..

Then maybe the recoil slide adjustment . I noticed around some struggle with getting that recoil slide right ..idk

Upvote 0

Yes, 2 pins and back off the compressor. That entire trigger assembly comes out as one. Just be mindful of a few little pins within the assembly.Just got to hold your mouth just right and thell go...lol

One more thing I forgot above

The trigger block just stays in that " cap" part and no worries of it falling put or apart to cause more work ? Looks like it all stays together as a unit ? So it's mostly pop the 2 pins out and back off the compressor ?

I guess I need to look over that cocking lever adjustment as well ..

Then maybe the recoil slide adjustment . I noticed around some struggle with getting that recoil slide right ..idk

The side lever has a rod that connects to the sliding compression chamber. Essentially a turnbucle type set up. You want that side lever to close (advance to foreword position against stock) to about 1.5" before feeling resistance. May take a bit of fiddling to get right. The rod flexes some, allows the lever to snap into place. Best to make sure when the rod flexes, it goes outwards (away from action into side lever).

As for recoil slide adjustment, manually advance the action forward into locked position without cocking. While holding the rifle by the stock and muzzle straight up, give the butt a smack (let's be mature). The action should return to rear position. This is how I kind of zero the setting (enough tension to hold action up, but light enough to drop with a smack). Removing the rear stock bolt/screw exposes the little brass(?) sledge mounting point. Inside of that is the sledge tensioner, adjusted via allen key (forget size). I'll stop here as I'm sure others know more than myself... But essentially heavy optics may need a little more tension than an open sight gun, just don't crank on it or you risk breaking stuff.

Last edited:

Upvote 0

No that slide adjust sounds close to what I remember from a hector post on help...

Your process sounds a lot simpler then most all I read up on .. I just need to rehearse it over a few times and I think I can handle it if ever needed now..

Can't wait for your test result on that uk power type spring .. should be sweet .

.

Thanks .

Your process sounds a lot simpler then most all I read up on .. I just need to rehearse it over a few times and I think I can handle it if ever needed now..

Can't wait for your test result on that uk power type spring .. should be sweet

Thanks .

Upvote 0

How far down the rabbit hole do you want to go LOL? Hector still makes some custom internals I think. And Nitrocrushr is supposed to be the installer for the Tony Leach skirtless 22mm setup.Think i will send it off , i could manage it but just do not want to . Thanks for all the replies , pictures and video .

Thanks again

also i would like it tuned down to around 10 FPE

Upvote 0