I have a. 177 chaser barrel and breech on a diana bandit hpa tube anyone have any idea on what I could do to get my shots the power is more than there just would like a few more shots I get 15 usable shots I'd be cool with losing a little fps to gain shot count thanks !

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Diana bandit/chaser

- Thread starter gavinsouth

- Start date

mmm ... if your using the hammer/spring/endcap from the chaser that may be affecting it .. without getting crazy and cutting springs etc, id say it wouldnt be too hard to fabricate one or grind the plastic endcap so you could 'adjust' the hammer spring with by its depth and maybe the use of washers andca long screw etc ... you get the idea ...

Upvote 0

Yeah, those things run pretty hot. Best advice would be to take a coil or two off of the hammer spring. But honestly.... this gun REALLY needs a lightweight hammer. The one if comes with is way too heavy, I think. I have two, myself. One is a .25 caliber tuned to 28fps currently. The other is a 177 regulated that gets 50 shots at 650fps

Upvote 0

Long_gun_Dallas any tips on getting my shot count anywhere near that ! I was thinking a longer lighter spring a reg and a power adjuster ! I'm new to pcps any help would be much appreciated! I was told to but a oring on the back of the hammer where the spring sits and one in the divit on the end cap to cut down hammer bounce would that work !? Thanks in advance

Upvote 0

First of all, look up some info on porting. It always helps to radius the port turn into the barrel at a minimum. Some of my other guns have more extensive port work, but that is all I did to this .177

It gets tricky because the air tube is already so small, cramming a regulator in there really reduces the volume/capacity. So, what you think you'd gain in shot count really almost entirely goes out the window if the reg/plenum takes up too much space.

I want to say I have my regulator dialed in around 105 bar. It is a huma regulator, but I have deleted the plenum on it to get more air volume in the tube. To do this I had to cut an oring groove into the face of the valve body to get the regulator to seal directly to it. (the plenum had 2 orings that sealed the regulator to the front of valve body)

The valve body oring groove I cut by hand, it wasn't fun, but it works. I also hogged out the valve body as much as I could... Even the front of it because it is the plenum now. I was also able to remove a lot of the hammer spring coils so I don't have any hammer/valve bounce now either (valve @105 bar is very easy to crack open) . Gun is super quiet and very soft shooting.

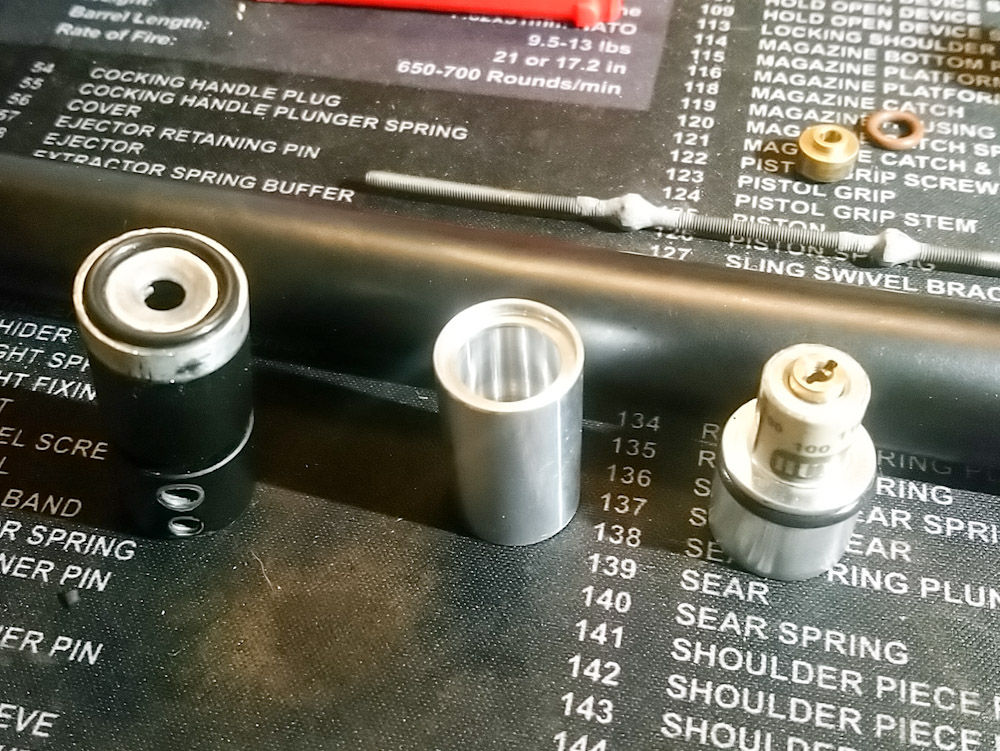

Here's the valve on the .177 and the plenum that is un-used in the middle

It gets tricky because the air tube is already so small, cramming a regulator in there really reduces the volume/capacity. So, what you think you'd gain in shot count really almost entirely goes out the window if the reg/plenum takes up too much space.

I want to say I have my regulator dialed in around 105 bar. It is a huma regulator, but I have deleted the plenum on it to get more air volume in the tube. To do this I had to cut an oring groove into the face of the valve body to get the regulator to seal directly to it. (the plenum had 2 orings that sealed the regulator to the front of valve body)

The valve body oring groove I cut by hand, it wasn't fun, but it works. I also hogged out the valve body as much as I could... Even the front of it because it is the plenum now. I was also able to remove a lot of the hammer spring coils so I don't have any hammer/valve bounce now either (valve @105 bar is very easy to crack open) . Gun is super quiet and very soft shooting.

Here's the valve on the .177 and the plenum that is un-used in the middle

Upvote 0

No, I don't believe an oring behind the hammer would help. Sometimes people put an oring in front of the hammer. The valve stem Ideally would sit about level with the oring so the ring would help absorb and cancel some hammer inertia when the valve is struck (simulateously with the oring).

Problem with that is the valve stem typically barely protrudes from the back of the valve housing on these guns. Leaving no room for an oring. The valve housing is held in place by a punched notch in the air tube, so you can't just reduce the length of the rear to expose more valve stem. Because doing so would cause it to lose its proper resting position on that notch in alignment with the trigger and upper. But the striking face of the hammer isn't all that large so you can recess the middle of the rear of the valve body some... But that won't help with the application of what is referred to as the bstaley mod (oring or something similar in front of hammer). All that would accomplish is to get more valve lift.

You could try to make and implement some sort of SSG. And use a lighter hammer. That would make a world of difference. https://hardairmagazine.com/ham-columns/conserving-air-in-pcps-hammer-bounce-and-the-ssg/

But if I got my hands on another one, for simplicity sake, and for effectiveness... I would make a delrin hammer with a peek striker. And by make, I mean I'd have someone Mill the parts to my spec because I don't have a lathe, and I would press them together. I'd also get several springs and figure out what works. I'd likely source a few that are stiffer than the factory one. That way I could get decent force with it still being cut shorter. And I could likely get it short enough to eleminate bounce. Problem is actually finding the right size spring. Likely would need to order from China off ali express.

The bell curve will still be there, but it would be flatter, and have more usable shots.

Now you don't have to reduce the hammer weight, I just think it would do a lot for the gun. The handling is also affected. At minimum I would cut a coil off the hammer spring and see how much it flattens the curve. If you are comfortable reducing the power some more, cut another coil. The curve will get flatter.

OH, if you do get a stronger hammer spring your cocking handle will likely break. I tapped my bolt to accept crosman 13xx handles. The notch where the bolt handle rest in the down position will likely need to be enlarged slightly, but I dont have to worry about it breaking again.

Problem with that is the valve stem typically barely protrudes from the back of the valve housing on these guns. Leaving no room for an oring. The valve housing is held in place by a punched notch in the air tube, so you can't just reduce the length of the rear to expose more valve stem. Because doing so would cause it to lose its proper resting position on that notch in alignment with the trigger and upper. But the striking face of the hammer isn't all that large so you can recess the middle of the rear of the valve body some... But that won't help with the application of what is referred to as the bstaley mod (oring or something similar in front of hammer). All that would accomplish is to get more valve lift.

You could try to make and implement some sort of SSG. And use a lighter hammer. That would make a world of difference. https://hardairmagazine.com/ham-columns/conserving-air-in-pcps-hammer-bounce-and-the-ssg/

But if I got my hands on another one, for simplicity sake, and for effectiveness... I would make a delrin hammer with a peek striker. And by make, I mean I'd have someone Mill the parts to my spec because I don't have a lathe, and I would press them together. I'd also get several springs and figure out what works. I'd likely source a few that are stiffer than the factory one. That way I could get decent force with it still being cut shorter. And I could likely get it short enough to eleminate bounce. Problem is actually finding the right size spring. Likely would need to order from China off ali express.

The bell curve will still be there, but it would be flatter, and have more usable shots.

Now you don't have to reduce the hammer weight, I just think it would do a lot for the gun. The handling is also affected. At minimum I would cut a coil off the hammer spring and see how much it flattens the curve. If you are comfortable reducing the power some more, cut another coil. The curve will get flatter.

OH, if you do get a stronger hammer spring your cocking handle will likely break. I tapped my bolt to accept crosman 13xx handles. The notch where the bolt handle rest in the down position will likely need to be enlarged slightly, but I dont have to worry about it breaking again.

Upvote 0

Thanks man ! I cut a coil off it last night didn't get to shoot it but it seems smoother and easier to cock I've thought about a ssg only problem I could think of is how the end cap bolts on any ideas on how I could do that !

Upvote 0

Nice.  I also found that the heavy hammer inertia disturbs the gun during the shot cycle, but I use adjueable length moderators and was able to effectively balance the gun out pretty well (length adjust weight on noclse of gun)

I also found that the heavy hammer inertia disturbs the gun during the shot cycle, but I use adjueable length moderators and was able to effectively balance the gun out pretty well (length adjust weight on noclse of gun)

Basically would have to find another way to fix the rear of the gun to the stock. Maybe tap a hole at an angle and then drill/counter-sink a hole for a bolt from the under/rear at an angle, would need to trim the bolt so it has enough hold, but isn't interfering with the ssg. Also might could make a custom end cap that is shallower and install a self-contained ssg inside the tube.

Basically would have to find another way to fix the rear of the gun to the stock. Maybe tap a hole at an angle and then drill/counter-sink a hole for a bolt from the under/rear at an angle, would need to trim the bolt so it has enough hold, but isn't interfering with the ssg. Also might could make a custom end cap that is shallower and install a self-contained ssg inside the tube.

Upvote 0

Kinda what I was thinking the first idea that came to my mind was to use the stock end cap drill it out bigger and tap it use around a 1in bolt grind it down so there's a spring guide on the end ! I can seem to think of a way to mount the cap that wouldn't be a pain to remove only thing I can come up with is use a set screw on the bottom in the stock location then for top one take take the bolt out of the breech use another set screw for that but then I'd have to take the bolt out of the breech to get to the screw just an idea

Upvote 0

I have it in a chaser carbine stock so I'd only have to cut the stock a little not much maybe a crosman 22xx power adjuster !? This I simply just a plinkster maybe take a bird or two here and there dont need or really even want a bunch of power just something easy and fun to shoot !

Upvote 0

Right. Yeah, easier route would be to get some stronger springs and make them shorter but you woukd have heavier final cocking force and would need to upgrade the bolt handle. I just modified an old brocock like this.

Lost no power, and got a lot better shot count, plus the gun is super quiet now. Either way it irks me to no end having hammer bounce on any of my guns. My .25 pp800 does, but there's no way around it at the power level it's at, not without a really custom valve, anyhow... Which I have no means to make. And accuracy is so good on it, I can't complain.

Lost no power, and got a lot better shot count, plus the gun is super quiet now. Either way it irks me to no end having hammer bounce on any of my guns. My .25 pp800 does, but there's no way around it at the power level it's at, not without a really custom valve, anyhow... Which I have no means to make. And accuracy is so good on it, I can't complain.

Upvote 0

Bagnall and kirkwood sells them https://spares.bagnallandkirkwood.co.uk/product/diana-bandit-silencer-adaptor-ref-bcm/

The thread protector is off of a 13xx mod adapter.

With the bandit you need to back bore the adapter since the muzzle is only half threaded. Also need to make sure the front of the sight post is level. Both mine were not causing the adapter to seat a bit crooked. Not good for how tight the bore on some of my mods are. I just used a file slowly and checked alignment while taking small amounts of the plastic off.

The thread protector is off of a 13xx mod adapter.

With the bandit you need to back bore the adapter since the muzzle is only half threaded. Also need to make sure the front of the sight post is level. Both mine were not causing the adapter to seat a bit crooked. Not good for how tight the bore on some of my mods are. I just used a file slowly and checked alignment while taking small amounts of the plastic off.

Upvote 0

Sweet I'll have to order me one I have a spare donny that would look cool on it ! Just a thought correct me if I'm wrong but would a longer hammer spring guide slow the hammer down!?

Upvote 0

No, in fact, what we really want is a faster, lighter hammer. And as little spring pre-load as possible. But what he have is a heavy hammer with an under-powered spring that's too long. A longer guide wont really do anything besides possibly make it impossible to cock the gun.

If you really want to flatten that curve, get a lighter hammer made, or you could get another factory hammer https://spares.bagnallandkirkwood.co.uk/product/replacement-hammer-cp1-cp2-pr900w-and-diana/ and attempt to lighten it up. Then like I said, find some stiffer springs (I cant really find a lot of sizes and wire thickness anywhere but ali express for some reason) sometiems you get luck and find them state side.

The happy place on my bandit is small, if you make the spring too short the guide will fall out of it's recess and sometimes it will lock up with more preload, sometimes it will go into it's recess and you'll have less preload, so shots wont be inconsisten. The spring has to be just long enough that it has some slack, but the guide doesn't fall out of the end cap recess. But the factory spring is too weak to run like this (unless you're using it at very low pressure like me via the regulator)

If you really want to flatten that curve, get a lighter hammer made, or you could get another factory hammer https://spares.bagnallandkirkwood.co.uk/product/replacement-hammer-cp1-cp2-pr900w-and-diana/ and attempt to lighten it up. Then like I said, find some stiffer springs (I cant really find a lot of sizes and wire thickness anywhere but ali express for some reason) sometiems you get luck and find them state side.

The happy place on my bandit is small, if you make the spring too short the guide will fall out of it's recess and sometimes it will lock up with more preload, sometimes it will go into it's recess and you'll have less preload, so shots wont be inconsisten. The spring has to be just long enough that it has some slack, but the guide doesn't fall out of the end cap recess. But the factory spring is too weak to run like this (unless you're using it at very low pressure like me via the regulator)

Upvote 0

Gotcha I'm just learning how to fool with pcps I've built alot of powder burners ! Mainly 10/22 based! We have alot of small-town hardware stores here in Southern Indiana I'm sure I could dig up a spring! Think I'll pull the hammer out and polish it and see where I'm at !

Upvote 0

Sounds good  I've had tough luck with any hardware stores here. But worth checking for sure.

I've had tough luck with any hardware stores here. But worth checking for sure.

Upvote 0