Hi,

I try and keep the lead in the backyard to a minimum so I use pellet traps.

I had a lot of problems in the past cleaning out my pellet traps.

I've had the metal traps with duct seal, the one with jeans in the box, the much version.

They al were very good untill you started shooting a lot and you had to clean them, man that was no fun.

Then I came across this YT video where they were testing with a box filled with sand. That gave me the following idea that I could just use a sieve to get the pellets out of the sand.

Worked like a charm you can see the sieve after the first 100 shot cleaning.

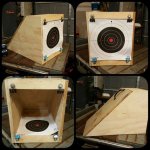

So I made some boxes of old boards to put the targets on filled them with fine dry sand.

This is important as wet sand gets hollewed out if you shoot in the same spot.

As to not get the sand wet I store them in the shed.The boxes need to be long as this dry sand will settle at an angle.

A sturdy handle is advised as they weigh quite a bit with a few 1000 pellets added to the sand .

.

You also only hear a thump from the pellet hitting the sand so it's also quiet.

After a very dry summer I also made a stand to keep the box of the ground.

I also now use a second fine sieve for the small pieces of lead from time to time.

Now I only clean the boxes out after 2000-3000 pellets and it takes very little time.

Hope this helps others spend more fun time shooting and less time doing cleaning of pellet traps.

I

I try and keep the lead in the backyard to a minimum so I use pellet traps.

I had a lot of problems in the past cleaning out my pellet traps.

I've had the metal traps with duct seal, the one with jeans in the box, the much version.

They al were very good untill you started shooting a lot and you had to clean them, man that was no fun.

Then I came across this YT video where they were testing with a box filled with sand.

Worked like a charm you can see the sieve after the first 100 shot cleaning.

So I made some boxes of old boards to put the targets on filled them with fine dry sand.

This is important as wet sand gets hollewed out if you shoot in the same spot.

As to not get the sand wet I store them in the shed.The boxes need to be long as this dry sand will settle at an angle.

A sturdy handle is advised as they weigh quite a bit with a few 1000 pellets added to the sand

You also only hear a thump from the pellet hitting the sand so it's also quiet.

After a very dry summer I also made a stand to keep the box of the ground.

I also now use a second fine sieve for the small pieces of lead from time to time.

Now I only clean the boxes out after 2000-3000 pellets and it takes very little time.

Hope this helps others spend more fun time shooting and less time doing cleaning of pellet traps.

I