its basically finished now and I don't see any possibility for further improvement.

as this is 3d printed and 3d printers quality vary a lot between each other I will release a full tutorial by the end of this week on how to print it (orientation, infill, support.. etc)

and how to install it safely incase your printer is not accurate because to increase sound reduction the hole tolerance is very tight (for example for 5.5mm the hole is 6mm).

for reference I'm using a prusa mk3s 3d printer.

my .22 350mm L2 was 36 fpe on standard baffle and now its 34/35 fpe so expect a little power loss for noise reduction.

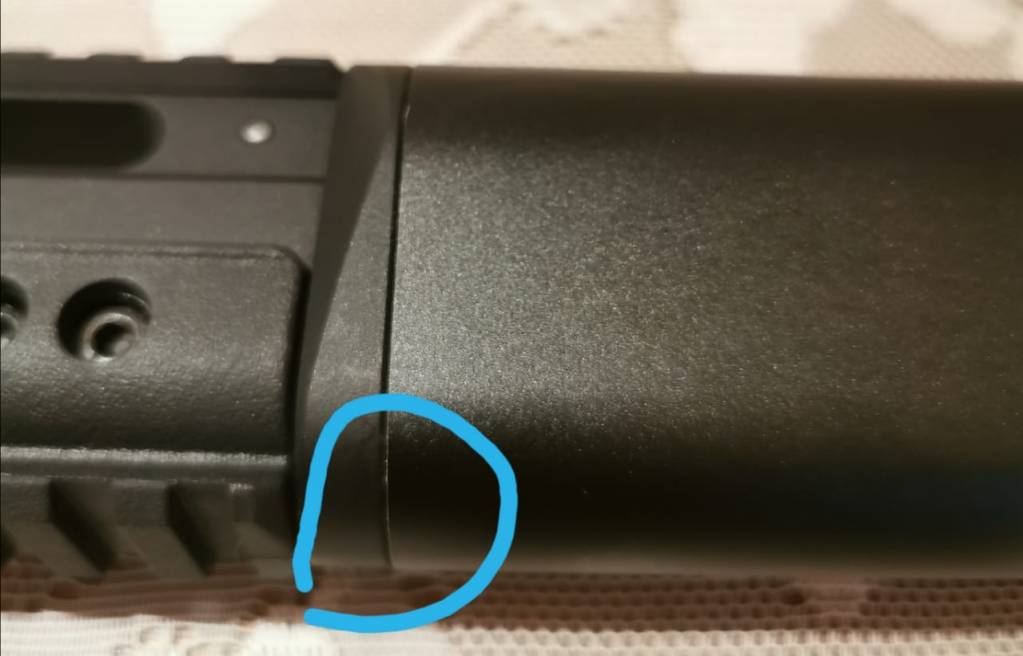

after 600ish shots the thin top of the baffle cracked so I beefed it up and its all good now.

also I noticed that the backside of the moderator is venting a good amount air on each shot.

I'm able to test it and shoot it in my 5x4 m room without damaging my ears. my metal trap though is very loud

as this is 3d printed and 3d printers quality vary a lot between each other I will release a full tutorial by the end of this week on how to print it (orientation, infill, support.. etc)

and how to install it safely incase your printer is not accurate because to increase sound reduction the hole tolerance is very tight (for example for 5.5mm the hole is 6mm).

for reference I'm using a prusa mk3s 3d printer.

my .22 350mm L2 was 36 fpe on standard baffle and now its 34/35 fpe so expect a little power loss for noise reduction.

after 600ish shots the thin top of the baffle cracked so I beefed it up and its all good now.

also I noticed that the backside of the moderator is venting a good amount air on each shot.

I'm able to test it and shoot it in my 5x4 m room without damaging my ears. my metal trap though is very loud

Upvote 0