Hello all,

Here is a reposting of some work I wrote about in a different forum subsection. I thought it would be helpful to put it where it belongs, in the resources section.

I disassembled, cleaned & re-lubed the bolt block on my Edgun R5M. I'm pretty sure the Lelya uses the exact same parts.

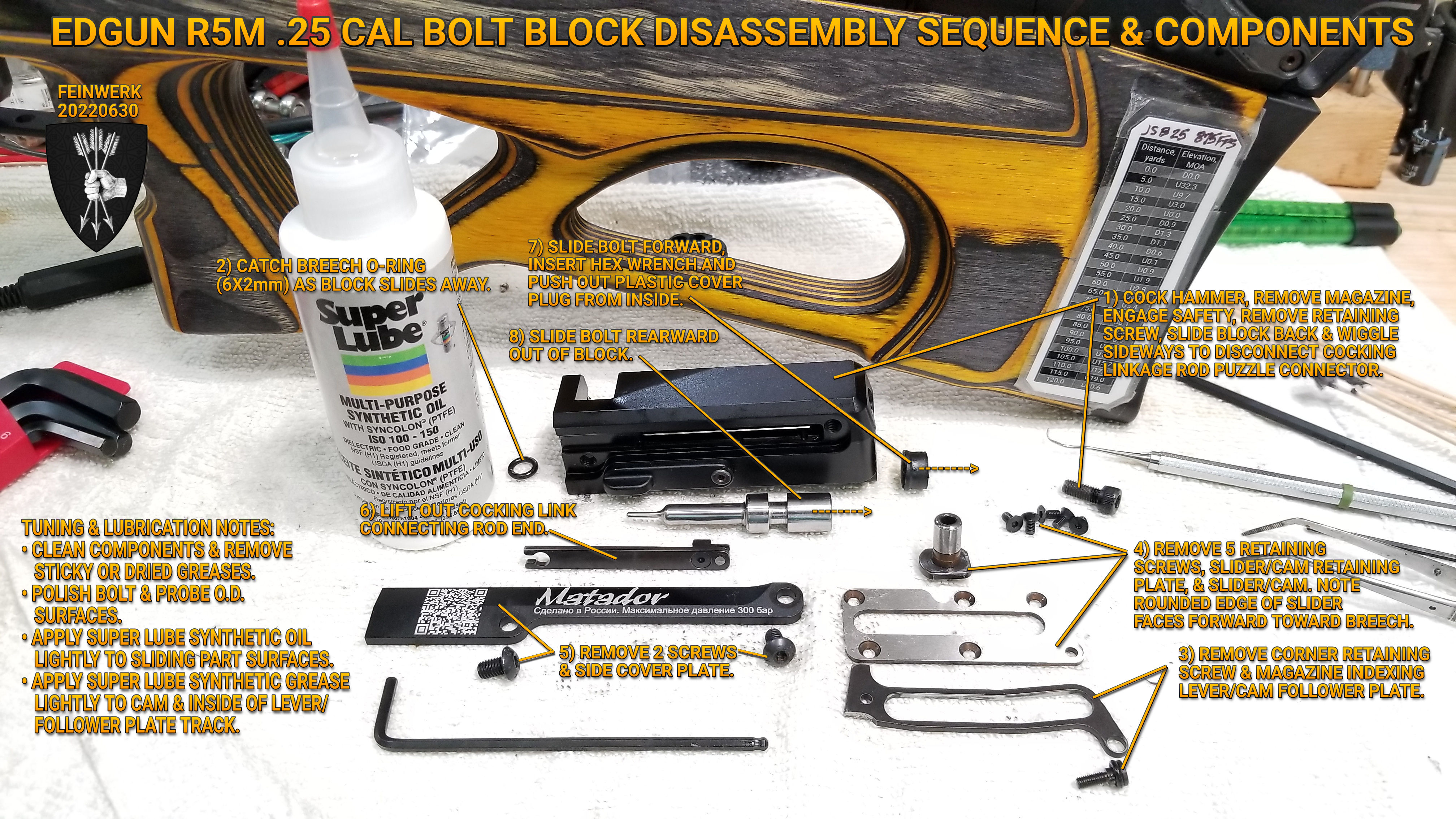

I've never seen this documented anywhere, so here are some pics and notes with my disassembly sequence. It was easy. The only trick was figuring out to use a long allen key to push out the rear bolt cover plug from the inside.

The factory flat head retaining screws were *very* tight and popped sharply as they released. I used a lot of torque to break them free, was afraid I was going to strip out the sockets. Be sure to use a quality wrench, apply increasing torque slowwwly, & wiggle slightly to get them to release.

Here's my master photo diagram with sequence:

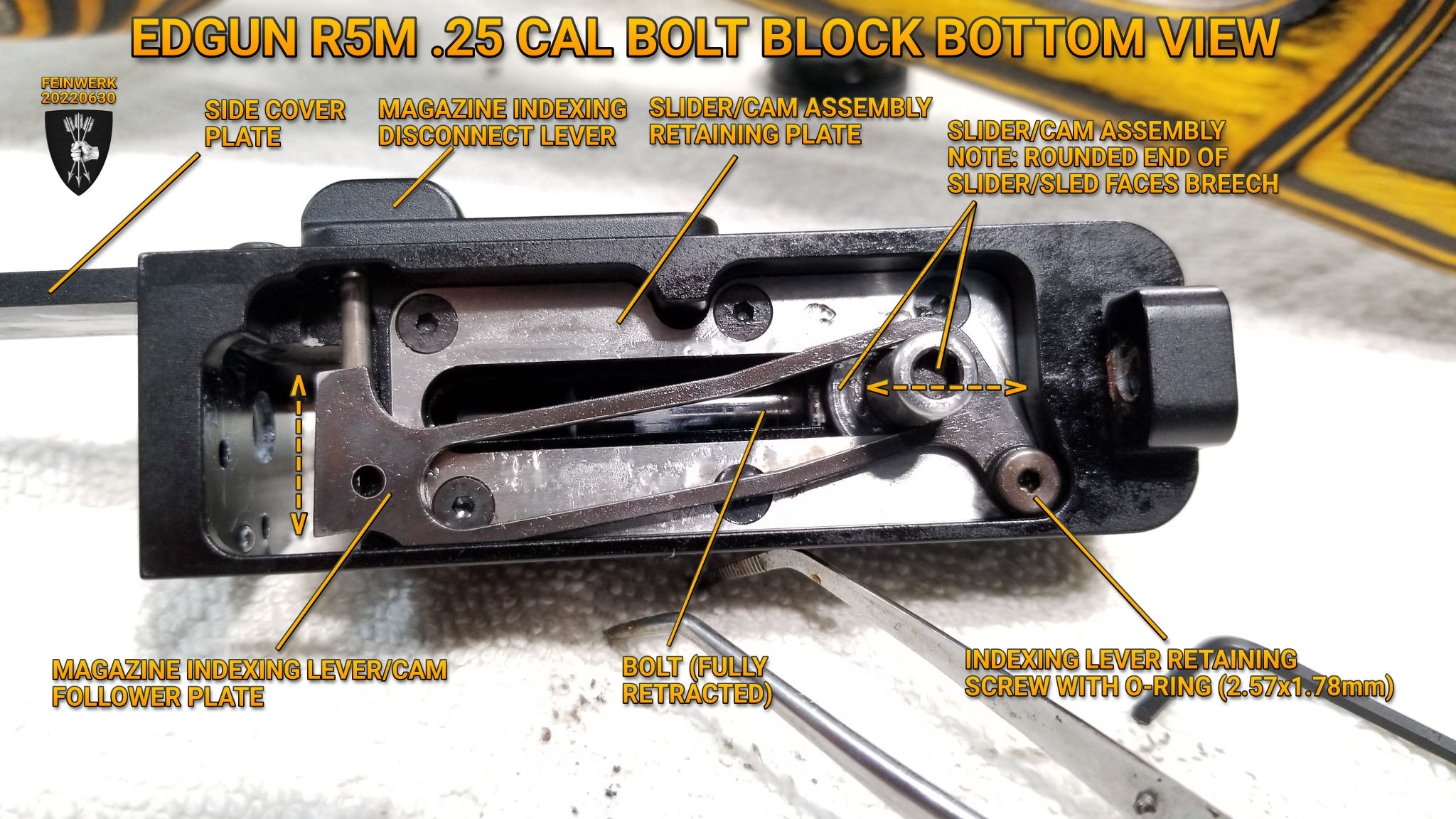

Here's the underside of the bolt block before disassembly. Here you can see why the design has a noticeable stack/ramp-up in the cocking force that some people may dislike; as the sliding cam reaches the end of its rearward stroke (towards the rear/right in this photo), it reaches the end of the slot in the magazine indexing lever and makes the lever pivot around its retaining screw. The far front edge (left in this photo) engages and turns the magazine. There is considerable mechanical disadvantage at this point in this action, plus there is no spring-assist in the magazine. It's simple and robust, at the cost of more perceived cocking effort at the rear position. Once the lubrication is refreshed, it's better:

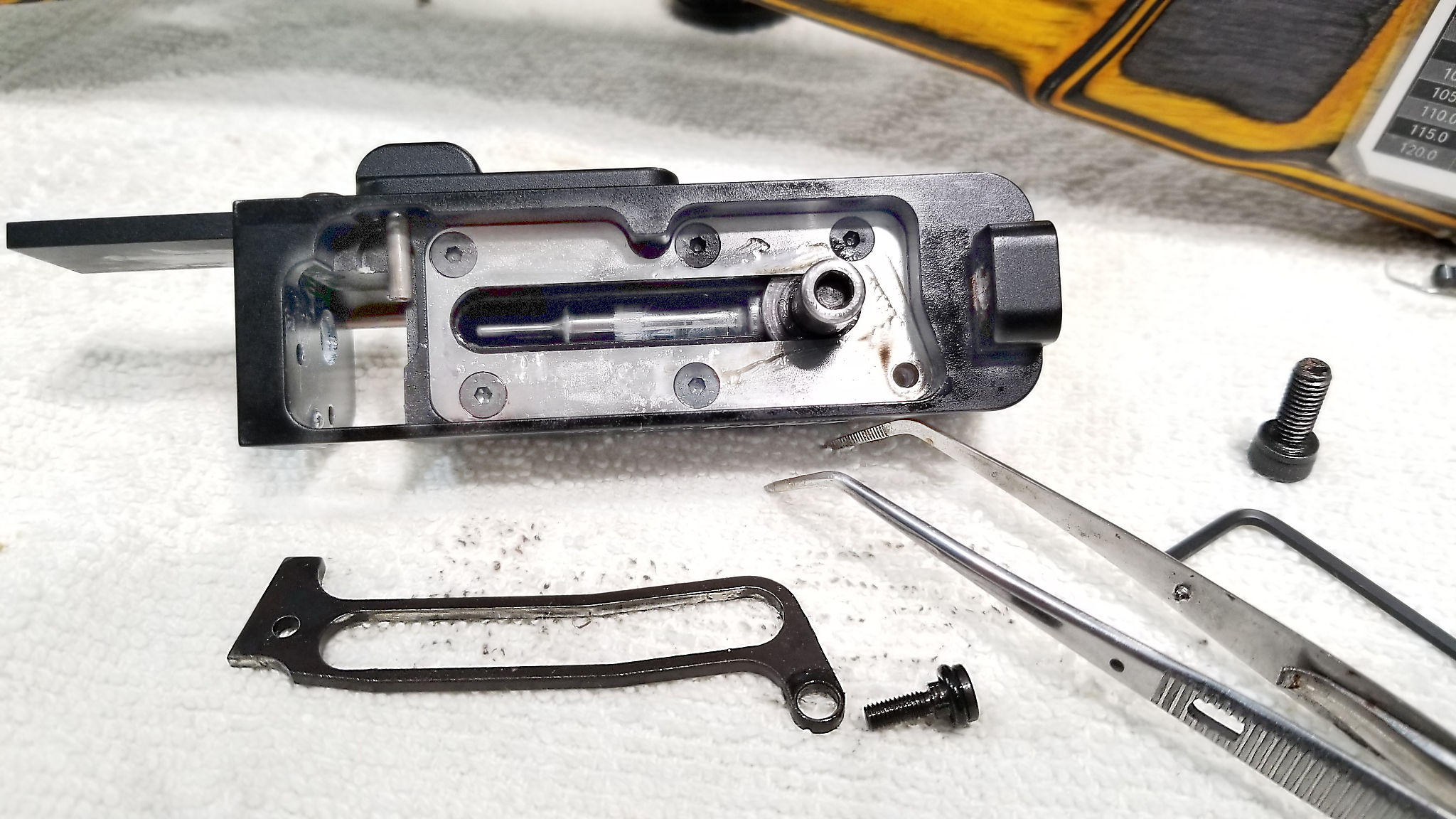

First off the bottom is the magazine indexing lever; one screw with o-ring anti-rattle spacer:

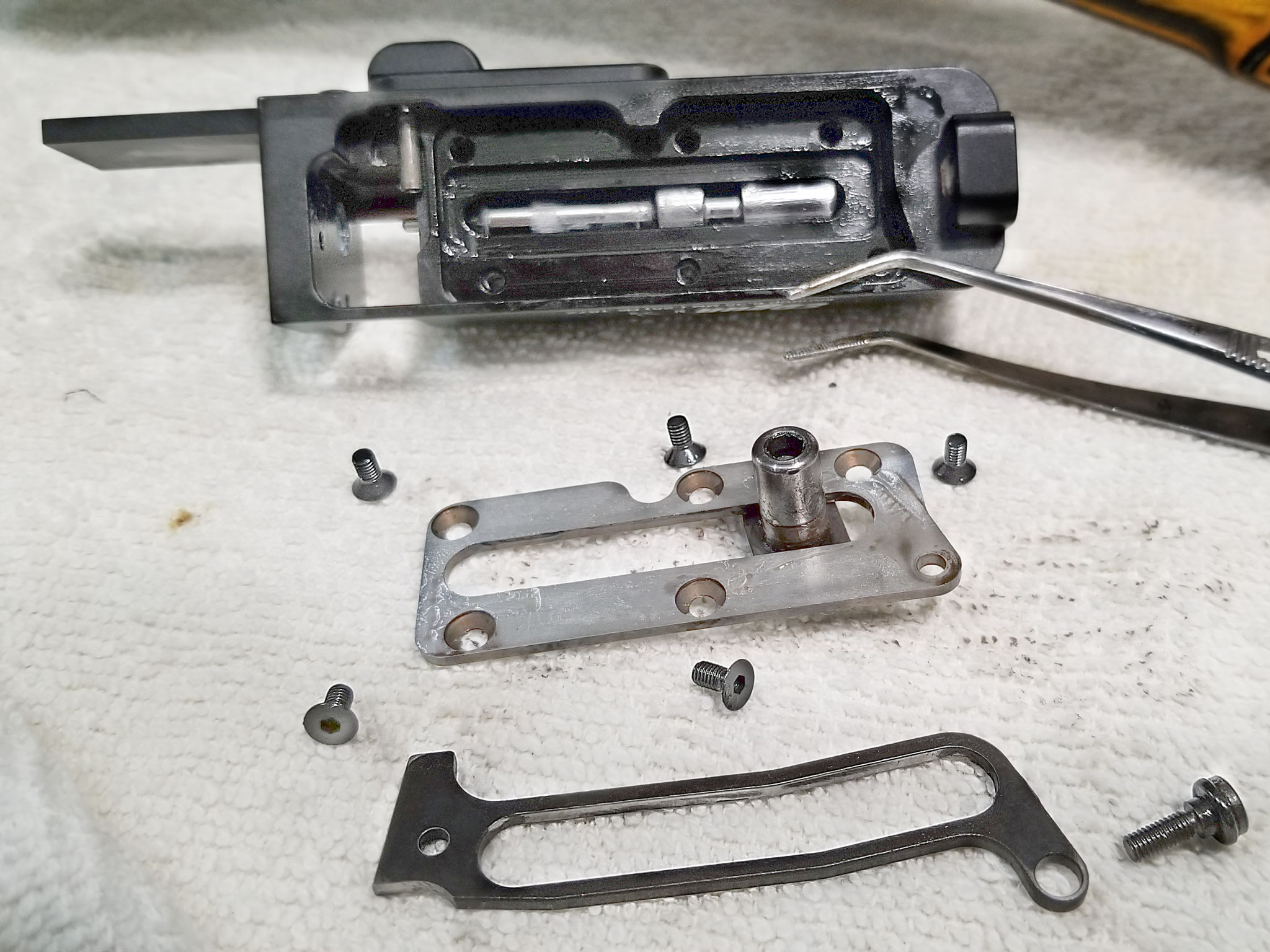

Next off is the slider/can retaining plate (5 screws) and slider. Use a quality wrench and torque slowly, these can be very tight:

The side cover plate comes off with 2 screws, freeing the cocking link 'puzzle piece'. Slide the bolt all the way forward and push out the rear bolt cover plug from the inside using an allen key:

Now you can slide the bolt out to the rear for inspection and polishing:

I chucked the bolt in my hand drill from both ends to polish the O.D. using 4000 grit 3M abrasive paper:

Here's the bolt after polishing. You can see some linear galling scratches on the rear O.D. (to the right), so the metal pairing or hardness may not be ideal between bolt and block, but it feels better now. I didn't attempt to polish the mating female pocket inside the block for lack of a good method. I'm avoiding grease here to reduce friction. I used light synthetic oil this time; I think powdered graphite or powdered dry molybdenum disulfide would be best next time.

The factory grease was getting sticky and causing excess drag on all the sliding parts. I used Super Lube synthetic oil lightly on all sliding parts and surfaces, except for the slider cam and lever plate track. These have much higher contact forces, so I used Super Lube synthetic grease there. Next time, I'll use molybdenum disulfide (best) for these higher-force, metal-on-metal sliding surfaces.

While I had the action out, I also took the opportunity to apply some molybdenum disulfide grease to the hammer & sear, which can be done using a small applicator through the side and bottom access holes in the trigger group area without any disassembly.

The rifle cocks easier and the trigger sure feels better (sorry, no measurements on pull weight). I can still feel some dragging during cocking though, perhaps coming from the bolt

handle carriage or forward cocking rod. That's a future exploratory project.

Regards,

Feinwerk

Here is a reposting of some work I wrote about in a different forum subsection. I thought it would be helpful to put it where it belongs, in the resources section.

I disassembled, cleaned & re-lubed the bolt block on my Edgun R5M. I'm pretty sure the Lelya uses the exact same parts.

I've never seen this documented anywhere, so here are some pics and notes with my disassembly sequence. It was easy. The only trick was figuring out to use a long allen key to push out the rear bolt cover plug from the inside.

The factory flat head retaining screws were *very* tight and popped sharply as they released. I used a lot of torque to break them free, was afraid I was going to strip out the sockets. Be sure to use a quality wrench, apply increasing torque slowwwly, & wiggle slightly to get them to release.

Here's my master photo diagram with sequence:

Here's the underside of the bolt block before disassembly. Here you can see why the design has a noticeable stack/ramp-up in the cocking force that some people may dislike; as the sliding cam reaches the end of its rearward stroke (towards the rear/right in this photo), it reaches the end of the slot in the magazine indexing lever and makes the lever pivot around its retaining screw. The far front edge (left in this photo) engages and turns the magazine. There is considerable mechanical disadvantage at this point in this action, plus there is no spring-assist in the magazine. It's simple and robust, at the cost of more perceived cocking effort at the rear position. Once the lubrication is refreshed, it's better:

First off the bottom is the magazine indexing lever; one screw with o-ring anti-rattle spacer:

Next off is the slider/can retaining plate (5 screws) and slider. Use a quality wrench and torque slowly, these can be very tight:

The side cover plate comes off with 2 screws, freeing the cocking link 'puzzle piece'. Slide the bolt all the way forward and push out the rear bolt cover plug from the inside using an allen key:

Now you can slide the bolt out to the rear for inspection and polishing:

I chucked the bolt in my hand drill from both ends to polish the O.D. using 4000 grit 3M abrasive paper:

Here's the bolt after polishing. You can see some linear galling scratches on the rear O.D. (to the right), so the metal pairing or hardness may not be ideal between bolt and block, but it feels better now. I didn't attempt to polish the mating female pocket inside the block for lack of a good method. I'm avoiding grease here to reduce friction. I used light synthetic oil this time; I think powdered graphite or powdered dry molybdenum disulfide would be best next time.

The factory grease was getting sticky and causing excess drag on all the sliding parts. I used Super Lube synthetic oil lightly on all sliding parts and surfaces, except for the slider cam and lever plate track. These have much higher contact forces, so I used Super Lube synthetic grease there. Next time, I'll use molybdenum disulfide (best) for these higher-force, metal-on-metal sliding surfaces.

While I had the action out, I also took the opportunity to apply some molybdenum disulfide grease to the hammer & sear, which can be done using a small applicator through the side and bottom access holes in the trigger group area without any disassembly.

The rifle cocks easier and the trigger sure feels better (sorry, no measurements on pull weight). I can still feel some dragging during cocking though, perhaps coming from the bolt

handle carriage or forward cocking rod. That's a future exploratory project.

Regards,

Feinwerk