Ok I think this is a bad design for the fx impact. The barrel is held in place by 1 sets setscrew. That screw is tighten on the barrel housing. It bites into the housing and damages it. I think this is bad design on fx. Why didn't they use a clamp style so when you tighten the screw it clamps the barrel into place. Or another way I think is better is drill a hole but not all the way through. So it would line up with the setscrew. When you screw the nut in it will line up with the hole and hold the barrel in place. I think these are better design than just having the setscrew bite into the house. Anyone have a way to prevent the housing from damage from the set screw? Maybe use a plastic set screw in place of the metal one?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FX Fx impact barrel setscrew damaging

- Thread starter 2fast2furious

- Start date

I "upgraded" both of my Impacts to the newer FX front barrel support style and the Huma tensioner assembly. Both have a clamp that holds the barrel housing in place which helps take some of the load off of the rear set screw. I wouldnt worry too much over a single set screw mark, but the ones pictured are from twisting and slipping while trying to remove or install the shroud or something.

I agree the FX design is not good and benefits from improvements. You can drop in a thin plastic disc under the set screw I suppose, but the front support is still going to be your best solution in my opinion. You can get them from Utah Air or HPP when in stock.

I agree the FX design is not good and benefits from improvements. You can drop in a thin plastic disc under the set screw I suppose, but the front support is still going to be your best solution in my opinion. You can get them from Utah Air or HPP when in stock.

Upvote 0

If you talking about the fx tension barrel kit that cost $70 plus shipping. Kinda high price to pay for a 2k gun when the gun should come stock with it. Barrel already have damage marks so no point but if I get a new barrel I will try putting a plastic disc in front of the metal screw.

Upvote 0

The OEM set screws have a cup point which is why they score the surface so easily. You can blunt and polish the tips and that will vastly reduce the propensity to dig in.

Or you can get set screws with an embedded tip made of either nylon or brass.

https://www.mcmaster.com/products/set-screws/ -> scroll down to the "Soft-Tip Set Screws" category

Or you can get set screws with an embedded tip made of either nylon or brass.

https://www.mcmaster.com/products/set-screws/ -> scroll down to the "Soft-Tip Set Screws" category

Upvote 0

Hello 2fast2furious,

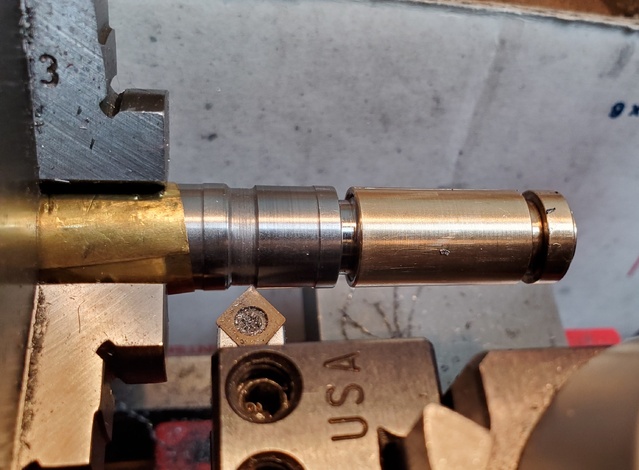

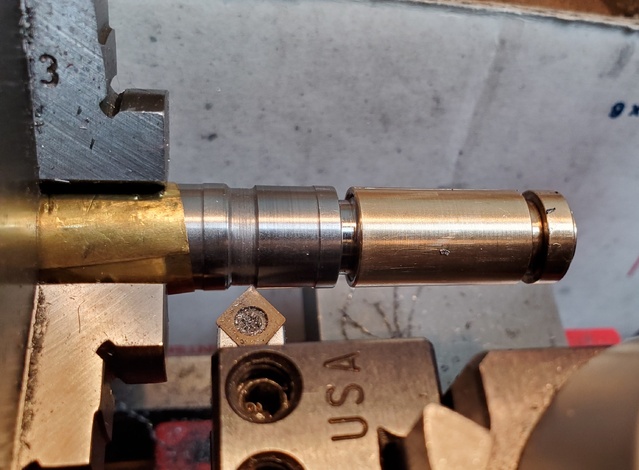

You could replace the set screw with a flat bottom set screw, or grind it your self for a nice even flat surface. I would even put a flat on the barrel if you had the capability to do it nicely/properly. A lot of the times, some shooters may want to index their barrels (using a custom brass port for the pellet/slug inlet), so I think that's why FX did it this way. I can see that FX also created a recessed area where the barrel would be inserted into the action, and the set screw would engage the outside diameter of the barrel, but inside the recessed area. This recess allows for the the damage associated with tightening the set screw.

If you want to remove the barrel and change it often, then yes I agree that maybe an alternate solution could resolve the issue.

If you want a secure fit, then creating a flat on the barrel and using a ground flat set screw will solve the issue I think.

You could replace the set screw with a flat bottom set screw, or grind it your self for a nice even flat surface. I would even put a flat on the barrel if you had the capability to do it nicely/properly. A lot of the times, some shooters may want to index their barrels (using a custom brass port for the pellet/slug inlet), so I think that's why FX did it this way. I can see that FX also created a recessed area where the barrel would be inserted into the action, and the set screw would engage the outside diameter of the barrel, but inside the recessed area. This recess allows for the the damage associated with tightening the set screw.

If you want to remove the barrel and change it often, then yes I agree that maybe an alternate solution could resolve the issue.

If you want a secure fit, then creating a flat on the barrel and using a ground flat set screw will solve the issue I think.

Upvote 0

Not really, but the full FX Tension kit does come with the newer front support. You can buy it separately from a few different online vendors. The newer M3 Impacts do come with this newer design support.If you talking about the fx tension barrel kit that cost $70 plus shipping. Kinda high price to pay for a 2k gun when the gun should come stock with it. Barrel already have damage marks so no point but if I get a new barrel I will try putting a plastic disc in front of the metal screw.

Upvote 0

Another solution is to drop a piece of lead shot down the hole before cinching the screw. But yes, that's a poor design decision.

GsT

GsT

Upvote 0

Is it one of them you get what you pay for ( and most times less) things . 150$ or 1500$ lol..Another solution is to drop a piece of lead shot down the hole before cinching the screw. But yes, that's a poor design decision.

GsT

Upvote 0

A lot of manufactures secure their barrel that way, example is the old puncher breaker too name one. It saves a buck

Upvote 0

cosmetic damage. It may not prevent the gun from functioning but it makes the barrel look ugly on a 2k gun. If your car, someone open their door and make a dent into the side of your car. Sure the car still drive but you don't consider that damage? SmhWould be hard pressed to call that damage.

I called utahairgun to try to buy it separately but they said no. They only sell it with the tension kit which is $70 plus $10 shipping. The only place I can find it is from bagnall and kirkwood and they sell for £58.41 pounds which translate to $74.38. So why would anyone pay that much for the clamp alone when the full kit is $70.Not really, but the full FX Tension kit does come with the newer front support. You can buy it separately from a few different online vendors. The newer M3 Impacts do come with this newer design support.

Upvote 0

Wouldn't the lead get squash and wedge between the hold and barrel preventing it from being pulled out? I was thinking trying what the user above mentioned using some hard plastic disc instead of lead.Another solution is to drop a piece of lead shot down the hole before cinching the screw. But yes, that's a poor design decision.

GsT

Upvote 0

Use a torch and melt while pulling ..Wouldn't the lead get squash and wedge between the hold and barrel preventing it from being pulled out? I was thinking trying what the user above mentioned using some hard plastic disc instead of lead.

Upvote 0

You do know the block that holds the barrel in place and also on the barrel itself have o rings right? Yeah I want to melt lead onto the barrel and inside the block and also melt all the o rings. XDUse a torch and melt while pulling ..

Upvote 0

Uhhhh I and everyone else would continually see the dent in the car door. Not even remotely comparable. It’s a little scratch on a surface the overwhelming vast majority of the time no one will see or know about. I’m a guy that never has used a set screw on a compound bow rest because it damages the surface of the bow even though the rest covers it up, but that nick is on the outer body of the bow. Many archers crank that thing down without a second thought. So I am a bit particular. I guess we are all different I just can’t imagine worrying about that.cosmetic damage. It may not prevent the gun from functioning but it makes the barrel look ugly on a 2k gun. If your car, someone open their door and make a dent into the side of your car. Sure the car still drive but you don't consider that damage? Smh

I called utahairgun to try to buy it separately but they said no. They only sell it with the tension kit which is $70 plus $10 shipping. The only place I can find it is from bagnall and kirkwood and they sell for £58.41 pounds which translate to $74.38. So why would anyone pay that much for the clamp alone when the full kit is $70.

Upvote 0

Ya them high dollar o rings gosh forbid you ruined them ..lolYou do know the block that holds the barrel in place and also on the barrel itself have o rings right? Yeah I want to melt lead onto the barrel and inside the block and also melt all the o rings. XD

Upvote 0

The cheapest, simplest solution is backing out the set screw before removing the barrel.

1. You wouldn't have to jerk and twist the barrel as hard to free it.

2. The set screw face wouldn't be against the barrel and wouldn't gouge the surface.

Now I admit I have only removed the barrels on my two Impacts once each to inspect the breech o-ring and neither was even scratched by the set screw.

1. You wouldn't have to jerk and twist the barrel as hard to free it.

2. The set screw face wouldn't be against the barrel and wouldn't gouge the surface.

Now I admit I have only removed the barrels on my two Impacts once each to inspect the breech o-ring and neither was even scratched by the set screw.

Upvote 0

Not unless you really cranked down on it. The pellet should deform slightly, but should fall out on its own. I've used the lead shot "trick" in many applications and it's never been a problem.Wouldn't the lead get squash and wedge between the hold and barrel preventing it from being pulled out? I was thinking trying what the user above mentioned using some hard plastic disc instead of lead.

GsT

Upvote 0

Simple fix... if you have the tools...

But I also run 2 Set-screws to secure my barrel..

Just making sure the barrel doesn't pull out when it is under tension....

But I also run 2 Set-screws to secure my barrel..

Just making sure the barrel doesn't pull out when it is under tension....

Upvote 0