You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fx Impact Fix & Mods for more FPS / FPE

- Thread starter AirSupply

- Start date

Edosan the hole I opened in TP is actually 7.95mm

I don’t have a peek or derlin rod to try to demonstrate it now. I took a factory pellet probe . Diameter of the head is 9.88mm . Try to insert the head inside to touch the vs . It fit and is moving still loosy....

I mean the vs is now 7.95mm . And there is space for peek seal 9.88 mm and can be even bigger around 10mm. That means the contact area of vs and peek/derlin seal is around 2mm. I think is more than enough . So why to not seal ?

This is my theory . Of course there is a big way from theory to action ..... but ok it seems logic. The difference is that the old removable type vs has more limitations than the newest ( intergrated) . I still remember last year when you post one photo with the newest valve house and you wrote something like this:” more space for bigger vs . 7.5 , 8 or why not and 9mm “”??

sorry Edosan if is not excacly the same ...I can’t find easy your post but was something like this ...personally I believe a peek/derlin valve stem seal around 9.50 mm will seal perfect ....

All trys I have read or talked, including several well known FX Impact experts, have fail over 7mm, with delrin and peek with integrated vs and old vs. Mine is 7mm (and is good) and I am testing bigger (but still working). Making integrated VS and seal is not hard (and I can see you did a good work there). So lets see how it goes.

Upvote 0

@Chris1973 Don't forget that air still needs to be able to pass between the circumference of the valve poppet and the valve housing.

When experimenting with the original PP valve housing with 6.7mm bore and a 0.5mm bigger than original PEEK poppet, I already experienced a loss in speed compared to the original PP kit.

That's why I have made a redesigned valve housing, by making use of the old (longer) valve stem I could move up the valve seat, creating a lot more flow compared with the PP kit.

https://www.airgunnation.com/topic/pp-valve-housing-2-0/

When experimenting with the original PP valve housing with 6.7mm bore and a 0.5mm bigger than original PEEK poppet, I already experienced a loss in speed compared to the original PP kit.

That's why I have made a redesigned valve housing, by making use of the old (longer) valve stem I could move up the valve seat, creating a lot more flow compared with the PP kit.

https://www.airgunnation.com/topic/pp-valve-housing-2-0/

Upvote 0

Wheatherby you are absolutely right.I never thought about the limitation of the air flow around the valve popet. All my tries have been concentrated to the surface of the vs and the valve house tp area .According to this theory which seems to be completely right with a big diameter valve popet the air flow will be always less than the required . The deals with the High pressure air are very tricky ( and dangerous first of all)and require high level knowledge which obviously I don’t have. Every modes we are trying is based in the knowledge and the tries that all the fx impact experts share with us in this forum and we want to thank you all of you for this. I am watching long time all your posts and I have to say that you are making amazing job .

Edosan obviously this is the reason why nobody still manage to take good results with bigger vs than 7mm..... There are too many different factors and limitations to be considered......but always we are trying step by step for the best.

Anyway I was more than happy with the oldest type of valve house and a 6.8 mm vs with all the rest well known modifications . The only mode I didn’t try so far is the opening of the rear block tp and really I don’t know if is necessary and if it will give me any remarkable results ...but I will try it very soon .

Continue the good job and be safe all of you guys

Thank you

Edosan obviously this is the reason why nobody still manage to take good results with bigger vs than 7mm..... There are too many different factors and limitations to be considered......but always we are trying step by step for the best.

Anyway I was more than happy with the oldest type of valve house and a 6.8 mm vs with all the rest well known modifications . The only mode I didn’t try so far is the opening of the rear block tp and really I don’t know if is necessary and if it will give me any remarkable results ...but I will try it very soon .

Continue the good job and be safe all of you guys

Thank you

Upvote 0

I am waiting for a confirmation who have parts in stock, I would like to have spares if anything goes wrong. PP Valve Housing and Valve Seal, also the Rear Block is on my list.

What epoxy/glue is a best for that delrin or PEEK poppet? Assume a pressfit shall be there as well?

I have access to Loctite super glue/gel but I can order some.

What epoxy/glue is a best for that delrin or PEEK poppet? Assume a pressfit shall be there as well?

I have access to Loctite super glue/gel but I can order some.

Upvote 0

Hi guys ...my Valve stop A17 19626 was broken into 2 pieces..it was over tight ...i try to replace with the old type ...buy it did not fit with valve stop from mk2 pp...is there any link about this new type of valve stop ? I intend to purchase it...thx

Upvote 0

Marcobet 38

i just checked the “fx airgun support page”” and the A17 is mentioned as19616 in all versions of impact if I am not wrong . I don’t know if by mistake the left in the page and the last version of impact with same code . Anyway if you live in USA I assume you need to contact Fx USA . If you are in Europe google “Bagnall and kirkwood “” in uk but try to explain them by email witch part you need because I see they have the 19616 available.

i just checked the “fx airgun support page”” and the A17 is mentioned as19616 in all versions of impact if I am not wrong . I don’t know if by mistake the left in the page and the last version of impact with same code . Anyway if you live in USA I assume you need to contact Fx USA . If you are in Europe google “Bagnall and kirkwood “” in uk but try to explain them by email witch part you need because I see they have the 19616 available.

Upvote 0

I don’t think that you need epoxy for the rod derlin (or peek) . You can use a red loctite and is not moving at all. In the picture is a peek material 7.5 mm for 7 mm valve seat . Just use red locktite In the metal threads as well and you can remove it later if necessary by heat.

Upvote 0

I have tested using peek pass 8mm bore, keep in mind the larger VS and peek will require more hammer impact to open valve--- larger PEEK has more surface mass to shut valve faster that's why guys loosing speed. I stop testing at 7.25 mm vs bore its the best combo with 357 power plant. impact has its power limit with current valving, the rear block with larger Valve housing with 360 degree plenum around VS is the next mods, not just from the rear of Valve rod. I envy you guys trying to get the most power of the current impact---> you guys already reach the limit now its time to slow it down for best accuracy!

Here is a failed attempt to get more speed with a larger rear block with 35cc plenum, learned that the VH need to be twice as large.

Ernest

Here is a failed attempt to get more speed with a larger rear block with 35cc plenum, learned that the VH need to be twice as large.

Ernest

Upvote 0

BigHun

I don’t think that you need epoxy for the rod derlin (or peek) . You can use a red loctite and is not moving at all. In the picture is a peek material 7.5 mm for 7 mm valve seat . Just use red locktite In the metal threads as well and you can remove it later if necessary by heat.

I would use delrin vs peek, because any flaws in a valve sitting surface a delrin can morph to micro scratches vs peek too stiff.

Last time I checked my stock valve housing have a smaller then 6.5 mm hole and the delrin puck is 7.5 mm. This means the delrin puck is sealing maximum 0.5mm all around a perimeter. Increasing a hole size to let say 7 mm could really need a bigger puck, but the total room inside the valve housing ID is only 10.6 mm. Not enough room for air flow. Only way to go around is maybe fabricating an electrode geometry and burn it out on EDM.

Cannot try cannot source the parts, nobody in my list of suppliers doesn't have the valve housing and valve rod assy. May need couple more months, looks like a perfect winter project (to be optimistic

Upvote 0

The geometry of the valve housing is limited by conventional machining. Maybe not necessary to replace the rear block.

I know that would be expensiver designing with different approach (since you already have classic machines) but for couple prototype parts you can outsource more complex geometries for 3D metal printing.

At my place in Toronto we have probably 5+ companies doing metal printing services, but I know also my engineering company was ordering 3d printed metal parts from US for way less.

I know that would be expensiver designing with different approach (since you already have classic machines) but for couple prototype parts you can outsource more complex geometries for 3D metal printing.

At my place in Toronto we have probably 5+ companies doing metal printing services, but I know also my engineering company was ordering 3d printed metal parts from US for way less.

Upvote 0

The geometry of the valve housing is limited by conventional machining. Maybe not necessary to replace the rear block.

I know that would be expensiver designing with different approach (since you already have classic machines) but for couple prototype parts you can outsource more complex geometries for 3D metal printing.

At my place in Toronto we have probably 5+ companies doing metal printing services, but I know also my engineering company was ordering 3d printed metal parts from US for way less.

I don't know if I would trust a valve housing that was 3D printed. There's a lot of pressure held back there by just a shouldered grub screw on that housing.

As far as getting good airflow on the exit side of the valve housing goes, I took a Dremel tool and small round carbide bit and opened up and smoothed the port on my valve housing with great success. It flows air smooth and transitions it up and out like the intake and exhaust tracts of a top fuel dragster; much better that the drilled and squared off holes from the factory. The only limitation now now is how far I could safely open up the size of the valve seat hole, based on the stock valve stem sealing area and the O-ring groove.

Upvote 0

I worked a lot as well with a dremel on the valve housing tp . First I drill vertical just a little the tp with an 8 mm drill because I want to keep the tp exactly 8 mm and not bigger and match it with the 8mm hole I open at rear block tp.I drilled carefully avoiding to damage the grove of the small o ring . After I remove a lot of material with a dremel and I made radius all the stock square edges as you mentioned .The vh tp opened at 7mm and I made a 7.55 mm rod seal from peek.

with regulator set at 169 bar ( extra high pressure huma) the gun reach to shoot 65 gr nsa at 1005 FPS . ( including many other modes ) . I tune it down at 977 where I found the sweet spot .The power is unbelievable..... and accuracy is there .

Upvote 0

Airgun -hobbyist

Airgun -hobbyist

I worked a lot as well with a dremel on the valve housing tp . First I drill vertical just a little the tp with an 8 mm drill because I want to keep the tp exactly 8 mm and not bigger and match it with the 8mm hole I open at rear block tp.I drilled carefully avoiding to damage the grove of the small o ring . After I remove a lot of material with a dremel and I made radius all the stock square edges as you mentioned .The vh tp opened at 7mm and I made a 7.55 mm rod seal from peek.

with regulator set at 169 bar ( extra high pressure huma) the gun reach to shoot 65 gr nsa at 1005 FPS . ( including many other modes ) . I tune it down at 977 where I found the sweet spot .The power is unbelievable..... and accuracy is there .

@Chris1973 Very nice work! As you see, opening up the valve seat along with smoothing and port matching those parts yields the best results in efficient air flow and the most gain in speed.

Upvote 0

Friend of my have machines I can use some labour time, but he doesn't want to touch the original parts. I can't get a valve rod and the valve housing this time of the year.

That on your picture is not a PP vh. I was planning instead of drilling that hole larger (right now the PP version is 7.2) to make it offset 0.5 per side (not towards orings but other way, sideways) and will look like elliptical, and to do the same to rear block. Also the Huma transfer port sideways have plenty of room.

That on your picture is not a PP vh. I was planning instead of drilling that hole larger (right now the PP version is 7.2) to make it offset 0.5 per side (not towards orings but other way, sideways) and will look like elliptical, and to do the same to rear block. Also the Huma transfer port sideways have plenty of room.

Upvote 0

bigHun the vh in the picture is not from Fx pp kit . The only part of pp kit I used is the hammer with the attached derlin .The power plenum is from Poland and I install it last year and generally I am very happy with this .The only problem that I have with this plenum is that is touching the barrel when the plenum is filled with air ( even if you align it perfect)and any time I need to remove the barrel for any reason (pellet jamming or cleaning ) I need to degas the gun and this is not the right way . To be honest the Fx pp plenum seems to my eyes more durable and the walls are little more thick . And because I am working the gun relatively in high pressures ( last year set reg at 185 bar for long time now at 169)I really would feel more calm and relaxed with Fx pp( that’s my opinion only) .

But I have a very bad experience with Fx pp kit. I bought 2 kits first week of jenuary 2020 . I remember it was first of year when I see it online and I order them . The tube that is connected in the action of the gun it was impossible to fit between the clamp ( even with the clamp grub screw completely out). Even when I removed the orings and I tried to fit it I press it a lot and I was damaging the two orings inside the action tunnel. I was thinking to place a screwdriver and to force a little bit the action clamp to open but I didnt want to scratch it so I quit.This happen before a month in my vacations so I didn’t Want to spend all my valuable time with this . I reinstall the Poland pp plenum and no problem apart attaching the barrel.

I believe personally because they just came in the market maybe it was a factory failure and the diameter was slightly bigger . I will try to deal with this in my next vacations ( I live and working out of my country so I am far from my airguns).

Regarding the vh transfer port if you make zoom the picture you will not see on the sides the walls because I made it already offset . Not only on the sides but forward to the back side of vs as well and little and carefully to the back side where is located the grove of the small oring of valve rod .specially on the sides there was too much material to remove and to polish .Long time the members “Airgun Hobbyist and I think “Heavy impact “ as well they mentioned the importance of this mode because probably they have experience with car exhausts .

A very very big gain in FPS I have as well with modified huma transfer port and handmade ( in lathe) pin probe . At least 45-50 FPS gain . I opened the two holes wide around 8.5 mm and I remove material with the dremel from the sides( as you mentioned above there is plenty of material to remove) . In the picture I have post you can see the scratches I made in the bottom (I should protect it with a rubber piece before start dremel works but anyway..)but after that I polish it very smoothly with a steel brash carefully .

The pin probe I made it one 1 mm longer than the original length and I manage to adjust it correct by turning few turns the probe holder block ( there is plenty of room for adjustments back or forward there by this way).

And of course I install in both sides an M4 grub screw in probe holder ( safelty first!)

Upvote 0

Is anyone feel the huma dual transfer port affected accuracy ? I feel accuravy is better using original TP

I am using pellets instead of slugs..sorry for my bad english

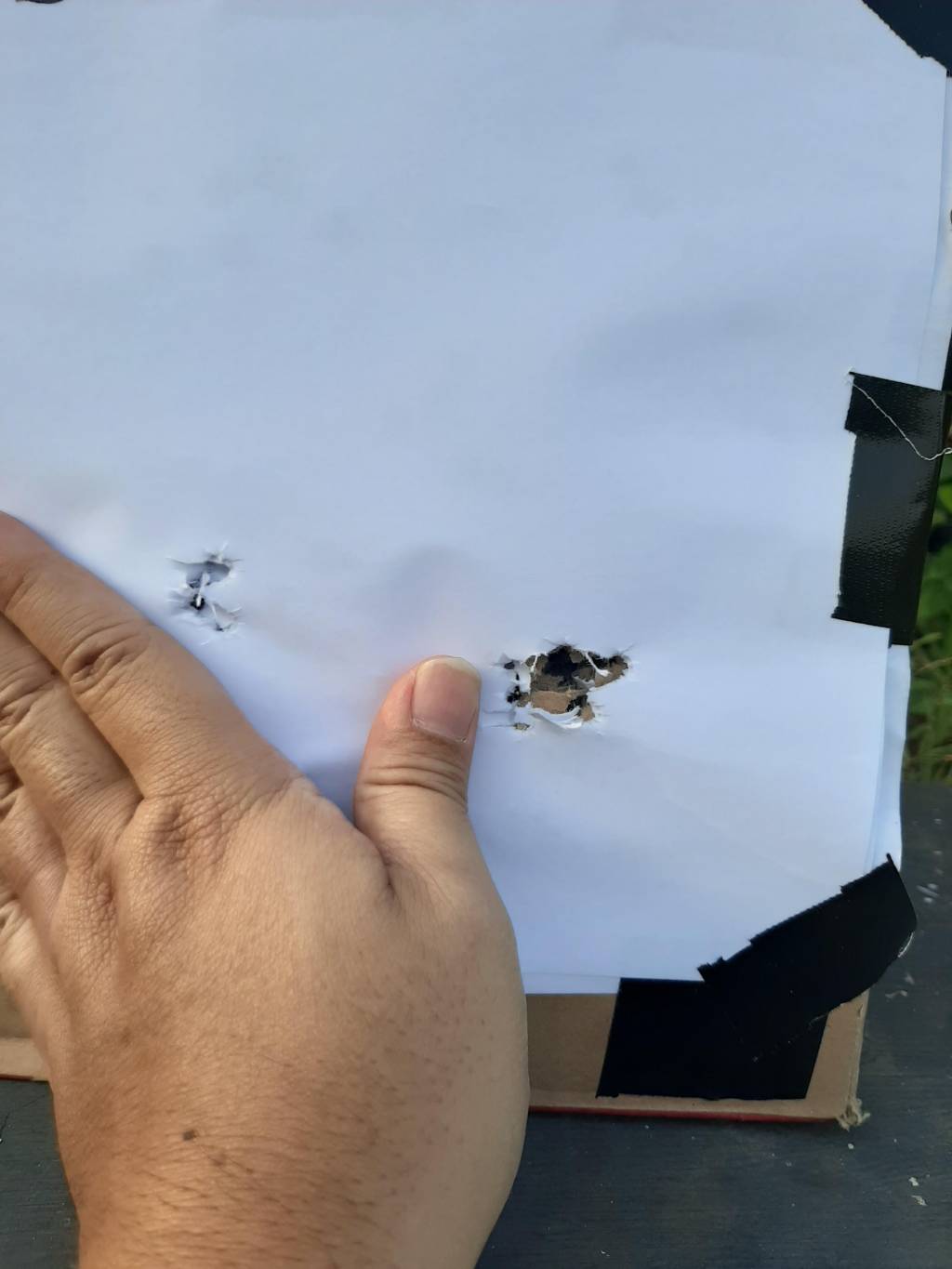

With huma dual TP 53 meter

With origin TP 10 shoots

I am using pellets instead of slugs..sorry for my bad english

With huma dual TP 53 meter

With origin TP 10 shoots

Upvote 0

I got a POI shift but accuracy was the same. and the POI shift was because the liner was removed and re-installed.

When changing the transfer port, did you loosen the liner lock and pulled the liner out a tad? that will allow the transfer port to be properly seated. I only say it because that happen to me or maybe if you did that then you re-installed the liner in a different clock to what it was?

or maybe if you did that then you re-installed the liner in a different clock to what it was?

Ahmed

When changing the transfer port, did you loosen the liner lock and pulled the liner out a tad? that will allow the transfer port to be properly seated. I only say it because that happen to me

Ahmed

Upvote 0

I pull the liner...now the accuracy become better with original TP and one of my friend put back the original TP as well...and he told me the accuracy back to normal for pellets...

Upvote 0