Hi.

We know that a standard FX Impact regulator piston is made of delrin. It has a pretty poor coefficient of thermal expansion comparing to brass. Brass is a much better choice. It is more rigid and tough which is pretty important when we think about high reg pressures. FX offers a brass piston as a replacement of the delrin one but it has two major limitations:

- some people reported problems with setting high pressure - the piston is longer than a delrin one and there is not enough threads to accomodate that,

- the air passage hole is too big. Huma regs use the air flow restrictor in a form of a screw. Thanks to that reg does not get hit that hard when there is a big pressure difference between the air bottle and the plenum. The plenum is replenished more gradually with flow restriction. Delrin piston has that flow restriction but sometimes reg recovery takes too much time. My goal was to deliver faster recovery time than a delrin piston but slower than FX brass piston.

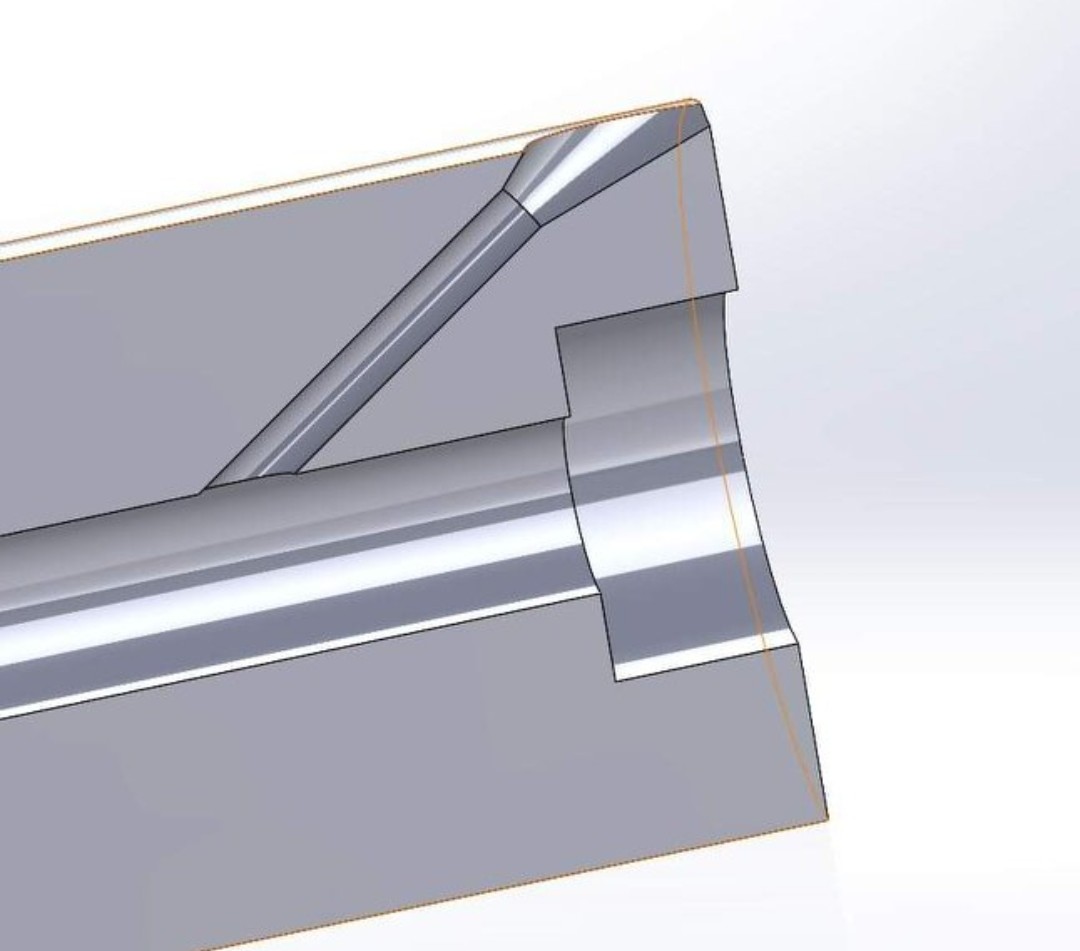

Because of the above limitations I came up with my own design and here it is.

The air passage holes are 0.3mm in diameter, where a human hair is up to 0.1mm in diameter. Drilling technique was pretty tricky to avoid drill breaking (the angle was the greatest challenge):

But the end effect is insane:

After the break in period there is virtually no reg creep.

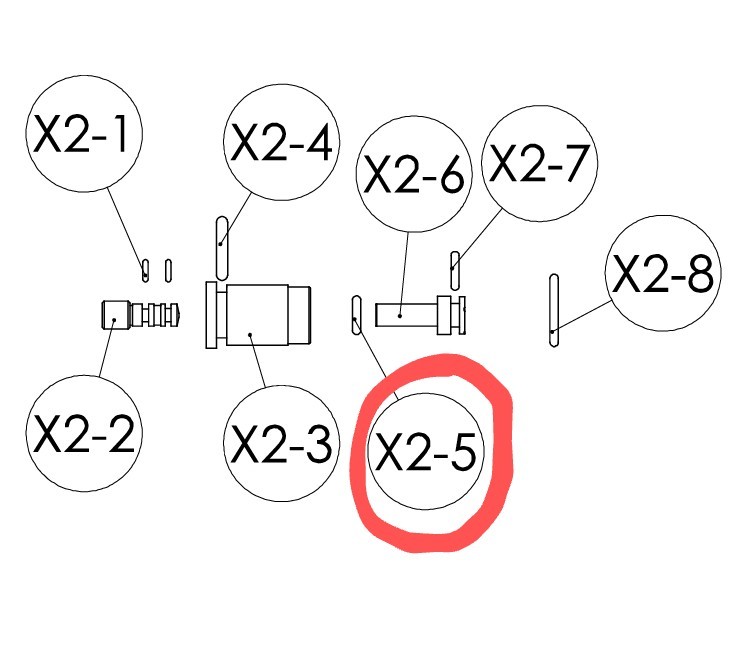

There are two versions of the piston:

- 4x0.3mm air passage holes - faster reg recovery time. Should work very nice as a bottle reg piston replacement,

-2x0.3mm air passage holes - slower reg recovery time. Dedicated as a plenum reg piston replacement.

The dimensions of my pistons are exactly the same as a delrin one. There is no problem with achieving high reg pressures.

If you are interested in my brass piston - just shoot me a PM. You will get the following package:

- brass reg piston,

- two orings: NBR70 and NBR90. The latter one should be placed in the reg case. Harder oring eliminates extrusion,

- a 0.25mm wire to make sure the air passages are clean.

Thanks!

We know that a standard FX Impact regulator piston is made of delrin. It has a pretty poor coefficient of thermal expansion comparing to brass. Brass is a much better choice. It is more rigid and tough which is pretty important when we think about high reg pressures. FX offers a brass piston as a replacement of the delrin one but it has two major limitations:

- some people reported problems with setting high pressure - the piston is longer than a delrin one and there is not enough threads to accomodate that,

- the air passage hole is too big. Huma regs use the air flow restrictor in a form of a screw. Thanks to that reg does not get hit that hard when there is a big pressure difference between the air bottle and the plenum. The plenum is replenished more gradually with flow restriction. Delrin piston has that flow restriction but sometimes reg recovery takes too much time. My goal was to deliver faster recovery time than a delrin piston but slower than FX brass piston.

Because of the above limitations I came up with my own design and here it is.

The air passage holes are 0.3mm in diameter, where a human hair is up to 0.1mm in diameter. Drilling technique was pretty tricky to avoid drill breaking (the angle was the greatest challenge):

But the end effect is insane:

After the break in period there is virtually no reg creep.

There are two versions of the piston:

- 4x0.3mm air passage holes - faster reg recovery time. Should work very nice as a bottle reg piston replacement,

-2x0.3mm air passage holes - slower reg recovery time. Dedicated as a plenum reg piston replacement.

The dimensions of my pistons are exactly the same as a delrin one. There is no problem with achieving high reg pressures.

If you are interested in my brass piston - just shoot me a PM. You will get the following package:

- brass reg piston,

- two orings: NBR70 and NBR90. The latter one should be placed in the reg case. Harder oring eliminates extrusion,

- a 0.25mm wire to make sure the air passages are clean.

Thanks!

Last edited: