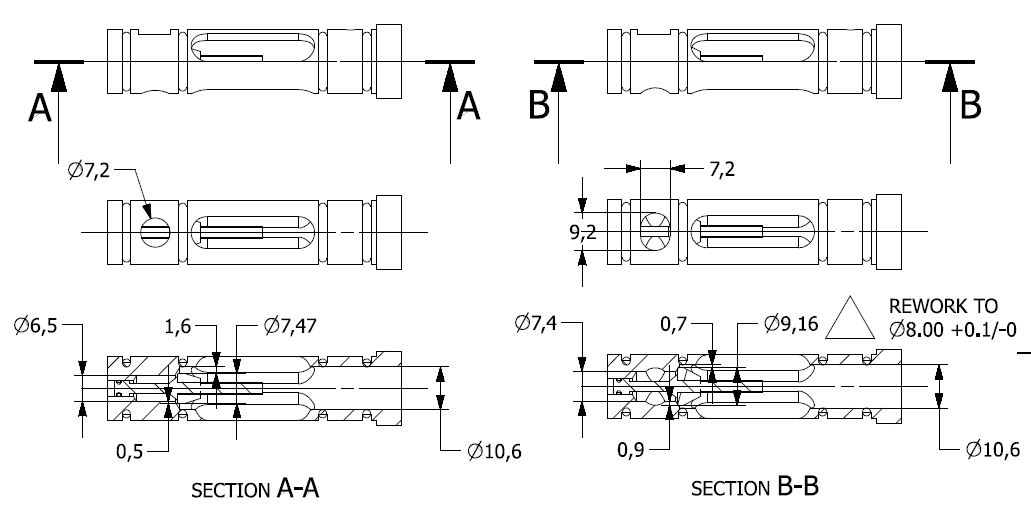

Im talking from memory now after two years but I think the ValveHouse ID is about 10mm + a hair. I did so many changes I wrote down everything in a book. Ya know we have that joke in my language: literate people writing it down - illiterate remembering

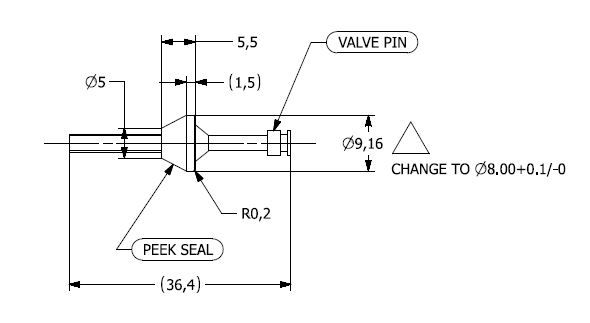

A 8.3-8.4 OD poppet is working well.

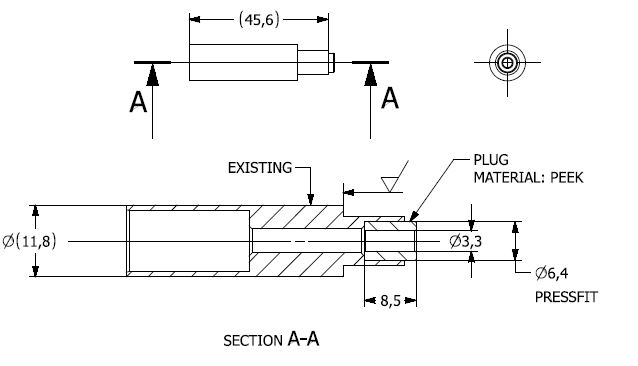

Was that a 7.3 bore size on my drawing and ended up with 7.5 mm ID hole in the Valve House? The problem there is to drive in a drill but the edge is cutting very little and want to push the center, especially that piece is a titanium....... you have a lathe, I would suggest bore that hole...

Usually whenever I give my drw to a machinist friend, I am never getting my parts within my specs. I was pißed so many times wanted to buy my own mini lathe just because of this. But stepped back because I may have 2-3 parts in a year and doesn't justify the cost for the machine.

A 8.3-8.4 OD poppet is working well.

Was that a 7.3 bore size on my drawing and ended up with 7.5 mm ID hole in the Valve House? The problem there is to drive in a drill but the edge is cutting very little and want to push the center, especially that piece is a titanium....... you have a lathe, I would suggest bore that hole...

Usually whenever I give my drw to a machinist friend, I am never getting my parts within my specs. I was pißed so many times wanted to buy my own mini lathe just because of this. But stepped back because I may have 2-3 parts in a year and doesn't justify the cost for the machine.

Last edited:

Upvote 0