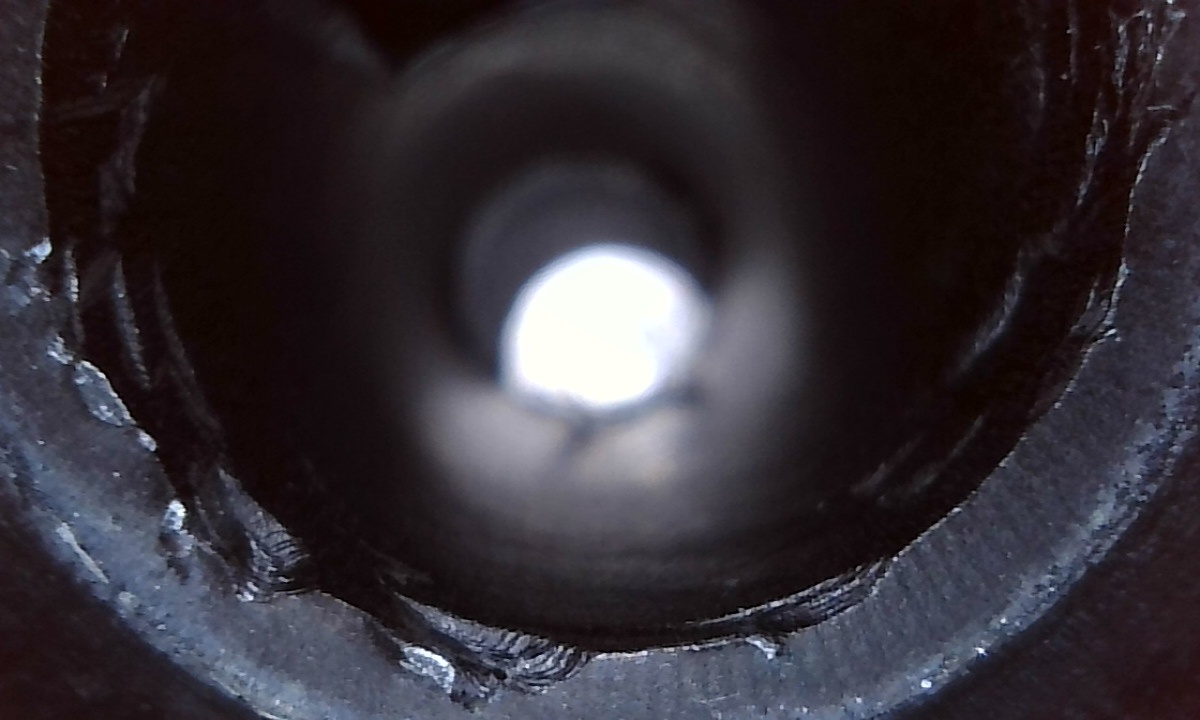

I'm not sure if anyone else experienced this. Had the King now for a few months and noticed a pretty big extreme spread and POI change. I keep my settings the same and clean the barrel when needed so I dug deeper. Looks like the hammer chamber in the block is getting debris possibly from the pellet probe assembly and getting jammed up with the hammer. When I took out the trigger, there was aluminum debris all over it. I took a few pics with my bore scope.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FX King block damage

- Thread starter Ta-Ta Toothie

- Start date

Or Monday morning.That is what we call a Friday afternoon gun. Not sure why it skipped QC though.

Upvote 0

I don't believe QC exists anymore. Especially over the past few years. Way to many things I received are not up to standards. Including work related parts and equipment. People just accept that crap they are giving.Or Monday morning.

Upvote 0

It appears the gouges were made prior to being sent to anodizing because they look to be colored. Of course it may just be the lighting/picture.Taking pride in your work is also a thing of the past.

The hammer, with normal tuning should never reach this hard stop but if a large gouge pulled enough material up, the hammer could strike it and break it, causing debris (that’s possibly anodized making it quite abrasive). It’s hard to tell from image but a couple of the gouges appear to have been flattened a bit.

It appears to be a machining boo boo that passed several qc checks. Reminds me of all the terrible barrel crowning instances with AEA and others.

Again….I may be wrong due to this image being difficult to see well.

Dave

Upvote 0

That is the problem when you have 1 guy running 2-3-4 CNC machines, CUZ something like that i would assume must have made some sort of sound.

Also any following items must have had severe problems, which should prompt a close examination of all products before the event.

It is one reason i have never really used my machinist education, CUZ while i can agt aroused watching a 5 axis machine do its thing, i would hate to " run " around between several machines.

Loved my grinding machine in my last job, but then suddenly i also had to run a keyway cutting machine, meaning i was working with 2 different cooling / lubrication substances, and i also instantly got stressed, CUZ no one asked me anything just dumped another machine on me, i even had to go myself to the guy that operated it before to learn how to run the damn thing CUZ i never done key tracks inside axles before only outside milling them into axles.

Anyway today they got a new CNC lathe that make those axles, it do it all including grinding and making keyways.

Also any following items must have had severe problems, which should prompt a close examination of all products before the event.

It is one reason i have never really used my machinist education, CUZ while i can agt aroused watching a 5 axis machine do its thing, i would hate to " run " around between several machines.

Loved my grinding machine in my last job, but then suddenly i also had to run a keyway cutting machine, meaning i was working with 2 different cooling / lubrication substances, and i also instantly got stressed, CUZ no one asked me anything just dumped another machine on me, i even had to go myself to the guy that operated it before to learn how to run the damn thing CUZ i never done key tracks inside axles before only outside milling them into axles.

Anyway today they got a new CNC lathe that make those axles, it do it all including grinding and making keyways.

Upvote 0

So it's not just in America? I'm meaning all the lazy, incompetent people who don't work or can't do a job by themselves, so the employer gives the good employees more work than they can handle because they must meet a productivity quota? Then the product tends to go to crap, which then drives up the cost so raises and company benefits suffer and they lay off even more people to meet that profit margin, and the cycle goes on and on?That is the problem when you have 1 guy running 2-3-4 CNC machines, CUZ something like that i would assume must have made some sort of sound.

Also any following items must have had severe problems, which should prompt a close examination of all products before the event.

It is one reason i have never really used my machinist education, CUZ while i can agt aroused watching a 5 axis machine do its thing, i would hate to " run " around between several machines.

Loved my grinding machine in my last job, but then suddenly i also had to run a keyway cutting machine, meaning i was working with 2 different cooling / lubrication substances, and i also instantly got stressed, CUZ no one asked me anything just dumped another machine on me, i even had to go myself to the guy that operated it before to learn how to run the damn thing CUZ i never done key tracks inside axles before only outside milling them into axles.

Anyway today they got a new CNC lathe that make those axles, it do it all including grinding and making keyways.

My last W2 job had me wearing 6-10 different hats a day, depending on who called in or "can't even" today. I went independent 5 years ago and won't ever go back.

Upvote 0

That block has been out over a year and they still can’t get it right….tell me how that justifies the price tag for the king. It doesn’t work so let’s charge more haha must be smoking the good stuff in Sweden

Upvote 0

No.

My last job was in a gear / transmission making factory, we was ISO 9001 and what ever it is called, ran LEAN / JIT and what not.

And even i budged a whole series of axles for big expensive hospital scanners, due to my grinding machine had been mistreated, so i had to change something to make those axles, but the kicker was to line that up / make it run within 1:100 mm, well it was POS and could some times take a hour to do, and of course one day o forgot to do that and just " slammed " the part in the machine ( like you was actually supposed to be able to do )

So things was all out of wack as without me adjusting the throw it would be like 6:100 of a mm throw which is no good when tolerances are supposed to be within 2:100 mm of each other.

Mind you when everything was A okay i was making tolerances where i had 6:1000 of a MM to make good with, so say loose 1:1000 mm in each end of the tolerance and you have 4:1000 mm left to make good with, and really making those little axles was 0 problem, i ruined maybe 1 in 100 on my 40 years or so old grinding machine ( TOS brand )

My last job was in a gear / transmission making factory, we was ISO 9001 and what ever it is called, ran LEAN / JIT and what not.

And even i budged a whole series of axles for big expensive hospital scanners, due to my grinding machine had been mistreated, so i had to change something to make those axles, but the kicker was to line that up / make it run within 1:100 mm, well it was POS and could some times take a hour to do, and of course one day o forgot to do that and just " slammed " the part in the machine ( like you was actually supposed to be able to do )

So things was all out of wack as without me adjusting the throw it would be like 6:100 of a mm throw which is no good when tolerances are supposed to be within 2:100 mm of each other.

Mind you when everything was A okay i was making tolerances where i had 6:1000 of a MM to make good with, so say loose 1:1000 mm in each end of the tolerance and you have 4:1000 mm left to make good with, and really making those little axles was 0 problem, i ruined maybe 1 in 100 on my 40 years or so old grinding machine ( TOS brand )

Upvote 0

Absolutely, engineering diffently would.I think fx would want to see what was causing the impacts marks, rather than just replace the damaged parts. Unless they know exactly what is causing it and give you the correct parts to repair it. This is assuming they think you know how to do that.

I would think that you would not want that issue to pop back up again.

Allen

Upvote 0

According to that guy, I probably reamed it myself and was trying to squeeze a F450 coil spring in the gun.Absolutely, engineering diffently would.

Upvote 0

The coil spring fronts do have a better turning radius than the older leaf or I-beam models!According to that guy, I probably reamed it myself and was trying to squeeze a F450 coil spring in the gun.

Upvote 0

You better believe it. My 2014 turns better than a camry.The coil spring fronts do have a better turning radius than the older leaf or I-beam models!

Upvote 0

I worked on the whole line up to 550 in F and E for 11 years. The older service trucks needed a 15 point turn to get in the lube bay!You better believe it. My 2014 turns better than a camry.

Upvote 0

Great chassis.I worked on the whole line up to 550 in F and E for 11 years. The older service trucks needed a 15 point turn to get in the lube bay!

Upvote 0

According to that guy, I probably reamed it myself and was trying to squeeze a F450 coil spring in the gun.

If you would thought it through you would have a coil bind issue if you could actually do that.

Glad someone recognized how it happened the additional pictures you sent . I did find it crazy that it cannot be felt when cocking this, but I must be visualizing the way the hammer works in a different way or the clearances are larger than I thought. See, I knew I would learn something.

Did the trigger stay the same when all this happened?

Allen

Upvote 0

Cocking changed a little, trigger didn't.If you would thought it through you would have a coil bind issue if you could actually do that.

Glad someone recognized how it happened the additional pictures you sent . I did find it crazy that it cannot be felt when cocking this, but I must be visualizing the way the hammer works in a different way or the clearances are larger than I thought. See, I knew I would learn something.

Did the trigger stay the same when all this happened?

Allen

Upvote 0

And for all I know, this was normal. This is my 1st FX.Cocking changed a little, trigger didn't.

Upvote 0

Having machine shop experience, those burrs look like TOOL marks of an end mill. Now knowing CNC manufactured possible cause could be a failure of tooling during the process.

Also note the color and it appears the plating, anodize or what ever the process used is there on the damaged areas meaning this is a QC issue of not catching a BAD PART while in the raw post machining and again not caught during assembly.

Also note the color and it appears the plating, anodize or what ever the process used is there on the damaged areas meaning this is a QC issue of not catching a BAD PART while in the raw post machining and again not caught during assembly.

Upvote 0