After the discussion in my previous thread I went ahead and ordered the .25 Maverick compact. I followed the video guide and instruction booklet on the first run. I shot the 25 grain JSB hades and have a few questions and complaints.

1. The factory reg was set at 120 bar and on power wheel #1 I was get 560 fps, is that expected? I think I got like 870fps at power wheel #7

2. tldr: The first reg was never set at the factory. I followed the instructions to degass the gun and reset both regs. When I unscrewed the second reg for the guage to read the first one the gauge shot up to the tank pressure instead. After degassing I screwed in the first reg until it stopped and filled the gun again, but the reg gauge was still reading tank pressure. I degassed the gun again and started screwing in the first reg more. I'm really cautious because I know it can damage by over tightening, but I had to give it some mustard to get past a burr in the threads and then it loosened up and seated properly.

3. I don't trust that the hammer spring tension was set properly. I followed Steve's tuning guide for JSBs and when I tried those settings I had 110 bar (10 more than him) and was 100 fps slower with the wheel set to 4. (He called it 0hs change from factory, but I can't trust that now) Is that much variation expected gun to gun?

4. How do I set the hammer spring back to "factory"?

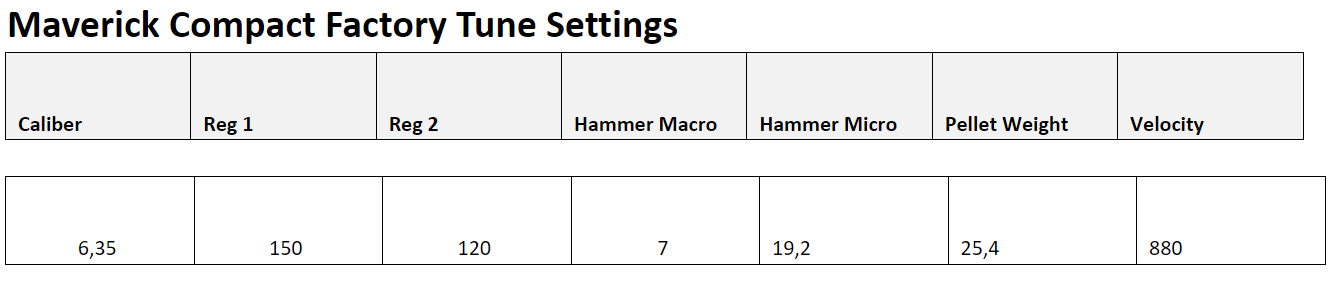

What does 19,2 mean? Is that turns out from full in? I know I need to "tune for the knee" but just wondering what that part of the chart means. I guess I could reverse engineer it and just aim for 880 with all other variables the same.

Edit: 5. regulator #2 sticks out of the housing. The book says “unscrew it flush with the housing” to see the first regulator pressure and what Steve did in the video matched that. Mine has to be out about 1/8th of an inch to have the same effect.

Anyway, I guess it could be worse but I expected better QC for the price point.

1. The factory reg was set at 120 bar and on power wheel #1 I was get 560 fps, is that expected? I think I got like 870fps at power wheel #7

2. tldr: The first reg was never set at the factory. I followed the instructions to degass the gun and reset both regs. When I unscrewed the second reg for the guage to read the first one the gauge shot up to the tank pressure instead. After degassing I screwed in the first reg until it stopped and filled the gun again, but the reg gauge was still reading tank pressure. I degassed the gun again and started screwing in the first reg more. I'm really cautious because I know it can damage by over tightening, but I had to give it some mustard to get past a burr in the threads and then it loosened up and seated properly.

3. I don't trust that the hammer spring tension was set properly. I followed Steve's tuning guide for JSBs and when I tried those settings I had 110 bar (10 more than him) and was 100 fps slower with the wheel set to 4. (He called it 0hs change from factory, but I can't trust that now) Is that much variation expected gun to gun?

4. How do I set the hammer spring back to "factory"?

What does 19,2 mean? Is that turns out from full in? I know I need to "tune for the knee" but just wondering what that part of the chart means. I guess I could reverse engineer it and just aim for 880 with all other variables the same.

Edit: 5. regulator #2 sticks out of the housing. The book says “unscrew it flush with the housing” to see the first regulator pressure and what Steve did in the video matched that. Mine has to be out about 1/8th of an inch to have the same effect.

Anyway, I guess it could be worse but I expected better QC for the price point.

Last edited: