Hi,

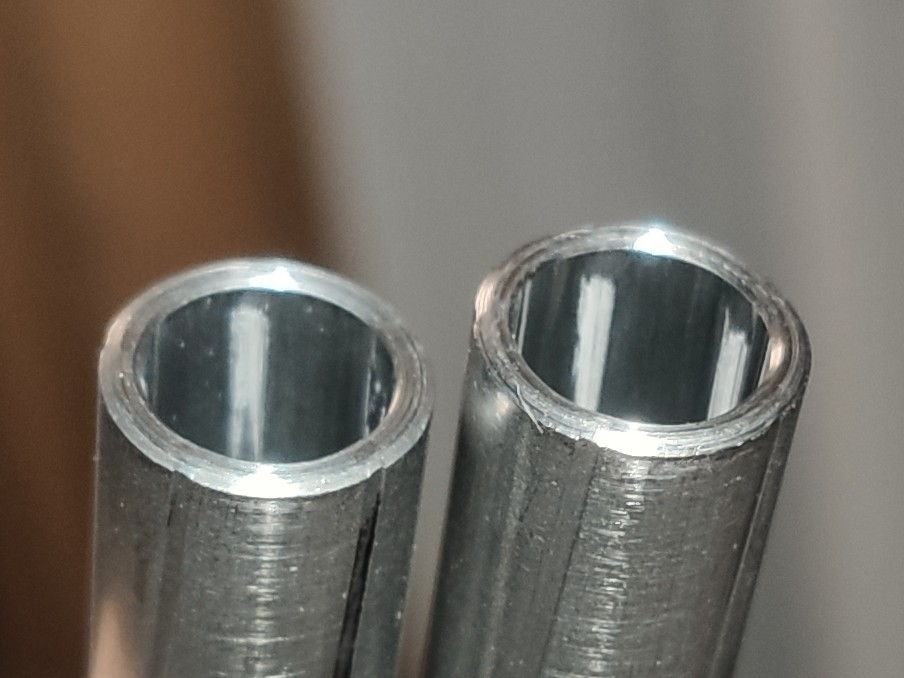

Please take a look at the leading marks of these liners:

It is evident there are no lands at the very end of the bore (EDIT: muzzle end, crown). I checked a couple of liners in multiple calibers and they are all like that. I think it may be dictated by the production process of making the rifling from the outside. They can't make the rifling to the very end because it would make a constriction there as there is no more material at the very end of the barrel - the material is from one side only so the steel would react in a different way there. However, there is no problem to remove the very end of the choke using a lathe and recrown. It is more expensive in production but can it help with precision?

If you exaggerate that the liner is like here:

What's your opinion on that?

Thanks!

Please take a look at the leading marks of these liners:

It is evident there are no lands at the very end of the bore (EDIT: muzzle end, crown). I checked a couple of liners in multiple calibers and they are all like that. I think it may be dictated by the production process of making the rifling from the outside. They can't make the rifling to the very end because it would make a constriction there as there is no more material at the very end of the barrel - the material is from one side only so the steel would react in a different way there. However, there is no problem to remove the very end of the choke using a lathe and recrown. It is more expensive in production but can it help with precision?

If you exaggerate that the liner is like here:

What's your opinion on that?

Thanks!

Last edited: