During a previous post, I made note of a very simple trigger mod for the newer Gamo CAT triggers. After that post, I had a couple of people PM me with questions regarding this modification, so I thought I'd add it to this forum to help me explain, and - hopefully - help out a few Gamo owners.

My first ever air rifle purchase was a Gamo Hornet Maxxim with the CAT 2-stage adjustable trigger and IGT piston. Aside from the garbage scope that came with the rifle, I really enjoyed the gun. I still shoot the gun a lot today as a matter of fact. Don't let the price fool you - with the right pellets it can shoot fantastic groups.

Anyways... after a few weeks of shooting, I decided to tinker with the trigger. It was a bit heavy IMO, and I wanted something lighter.

If you read through the instructions, it provides information on softening the trigger, but I honestly couldn't tell the difference. The problem was - the screw is too short to get the trigger pull light and crisp.

Here is the location of the screw you tighten or loosen in order to change the trigger tension during stage 2 of the trigger pull.

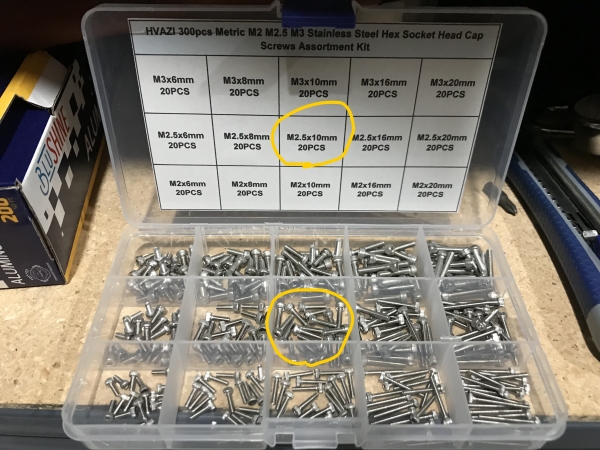

The stock trigger tension screw is a 2.5mm x 6mm. I took this screw completely out and replaced it with an 8mm. I could feel the difference, but I still was not happy with the trigger tension required to fire the rifle. So I went even longer... I replace the 8mm with a 10mm, and I hit perfection.

The screws I used were purchased off Amazon. Here is a pic.

A few VERY IMPORTANT items of note for anyone who wants to try this.

DO NOT tighten the 10mm screw all the way down. Doing so will result in a rifle that fires immediately after cocking. The trigger latch will not grab the piston rod well enough to retain tension.

My suggestion is to tighten the screw down about 3/4 of the way. Test fire the rifle, and make 1/4 turns inward until you reach the desired pull.

Once you hit a point where the trigger tension is ideal, for you, use a fine tip black sharpie and mark the head of the screw. This will allow you to see if the screw is working itself loose due to the vibration of the firing sequence.

As you can see is this picture, the screw is not fully engaged with several treads still exposed. You will also see the line I put on the head.

That's all there is to it.

Hopefully this helps...

Joe

My first ever air rifle purchase was a Gamo Hornet Maxxim with the CAT 2-stage adjustable trigger and IGT piston. Aside from the garbage scope that came with the rifle, I really enjoyed the gun. I still shoot the gun a lot today as a matter of fact. Don't let the price fool you - with the right pellets it can shoot fantastic groups.

Anyways... after a few weeks of shooting, I decided to tinker with the trigger. It was a bit heavy IMO, and I wanted something lighter.

If you read through the instructions, it provides information on softening the trigger, but I honestly couldn't tell the difference. The problem was - the screw is too short to get the trigger pull light and crisp.

Here is the location of the screw you tighten or loosen in order to change the trigger tension during stage 2 of the trigger pull.

The stock trigger tension screw is a 2.5mm x 6mm. I took this screw completely out and replaced it with an 8mm. I could feel the difference, but I still was not happy with the trigger tension required to fire the rifle. So I went even longer... I replace the 8mm with a 10mm, and I hit perfection.

The screws I used were purchased off Amazon. Here is a pic.

A few VERY IMPORTANT items of note for anyone who wants to try this.

DO NOT tighten the 10mm screw all the way down. Doing so will result in a rifle that fires immediately after cocking. The trigger latch will not grab the piston rod well enough to retain tension.

My suggestion is to tighten the screw down about 3/4 of the way. Test fire the rifle, and make 1/4 turns inward until you reach the desired pull.

Once you hit a point where the trigger tension is ideal, for you, use a fine tip black sharpie and mark the head of the screw. This will allow you to see if the screw is working itself loose due to the vibration of the firing sequence.

As you can see is this picture, the screw is not fully engaged with several treads still exposed. You will also see the line I put on the head.

That's all there is to it.

Hopefully this helps...

Joe