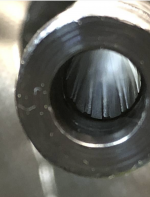

I'm shooting the G2, .22cal today, doing some plinking at 75 yards, and noticed that my accuracy was down, which I confirmed with targets.

I noticed that I could clearly see a spiraling pellet path as well.

I am still shooting copper clad Baracudas which were accurate a few months ago.

I guess its time to pull a patch, and or switch ammo.

I noticed that I could clearly see a spiraling pellet path as well.

I am still shooting copper clad Baracudas which were accurate a few months ago.

I guess its time to pull a patch, and or switch ammo.

Last edited: