You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Getting Technical With Barrel Twist Ratios - Pellet Stability & Env. Variables

- Thread starter azuaro

- Start date

AZ: excellent over-view. ☺

A query re' the statement: How much rotation is needed for stabilization?Too little and the projectile will YAW and possibly TUMBLE, too much and it will over stabilize the pellet which also is negative, but it is always better to have MORE than LESS…in other words, an over-stabilized projectile is always more accurate than an under-stabilized one.

This was the commonly held view right up to the advent of smooth twist barrels. But, if anything, the smooth twist barrels, with their lower effective twist rate, seem to be better at long range than their traditionally rifled counterparts.

A query re' the statement: How much rotation is needed for stabilization?Too little and the projectile will YAW and possibly TUMBLE, too much and it will over stabilize the pellet which also is negative, but it is always better to have MORE than LESS…in other words, an over-stabilized projectile is always more accurate than an under-stabilized one.

This was the commonly held view right up to the advent of smooth twist barrels. But, if anything, the smooth twist barrels, with their lower effective twist rate, seem to be better at long range than their traditionally rifled counterparts.

Upvote 0

If memory serves; I believe Yrrah tested Smooth Twist barrels some time ago and showed that the pellet rpm induced was significantly lower than that predicted from the rifling twist rate. This information was passed on to FX which, at the time, was news to them. The conclusion, I believe, was that the pellet was skidding through the rifling resulting in a lower effective twist rate than actual.

Upvote 0

Thanks, guys, for a very interesting thread. I have been interested for a very long time in what makes one barrel more accurate at a given distance than another. When I started bagging rabbits with my Blue Streak, the only consideration I had was being able to keep the hits within the very small brain area at up to eighty yards. Now, at the very least, I have something more to consider when I observe pellets wobbling in flight or turning sideways (key holing) at given distances. Please keep up the excellent work!

Upvote 0

Long response to both authors:.

My ST .22 barrel has these stats:

Actual rifling twist rate is 1:16" given to me in conversation with Fredrik.

My marked pellet dual and triple screen tests showed effective spin rates of 1:64" with JSB Exact 15.9 gr; 1:44" with 21 gr Baracuda Match; and 1: 90" inch with the more bullet-like 25.4 gr JSB Monsters which it also shoots very well.

Quote me:..."The actual spin rate is approx average 1:64 inches when averaged from two tests through 16" separated screens and three tests through 8" separated screens.

Raw data at 16" screen gap was 90 degrees rotation and 91 degrees rotation = 1:64" and 1:63.3" spin rate respectively.

Raw data for 8" screen gap was 44 d, 44 d, 47 degrees rotation for 1:65.4", 1:65.4", 1:61.3" spin rate respectively. ... " Unquote.

My .22 barrel is a later iteration than Dan Brown's which he measured similarly to have a 1:162" initial spin rate. (Dan shot a sub 1/2" 100 yard 5 shot group with that barrel).

When in conversation with Fredrik I relayed my findings, He was most surprised and spent the whole next weekend doing the tests. He subsequently phoned to agree with my findings and we discussed the possibility of changes to the rifling to perhaps get a better correlation between barrel twist rate and pellet spin rate. But we agreed that the accuracy of the barrels as they stood would hardly warrant a change.

It would appear that one reason for differing results is that different velocities and different pellet weights produce different pellet momentum. Thus when impacting the rifling in the last couple of inches of an ST barrel the degree of stripping is impulse affected..

In any case the pellets never actually engage the rifling and so show only five "flats": with no grooves from the barrel's lands.

A shot Baracuda pellet showing the "flats" from skidding through the 1:16" barrel twist rate and emerging in this case with a spin rate of 1:44":

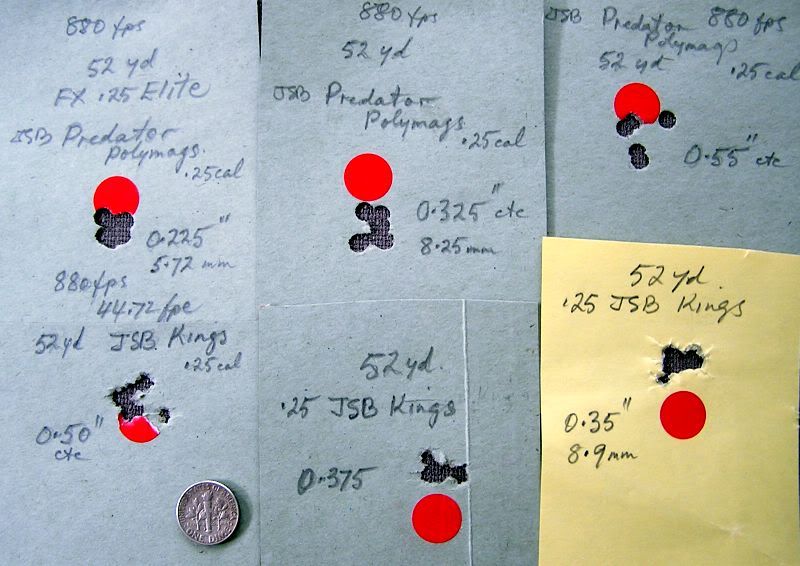

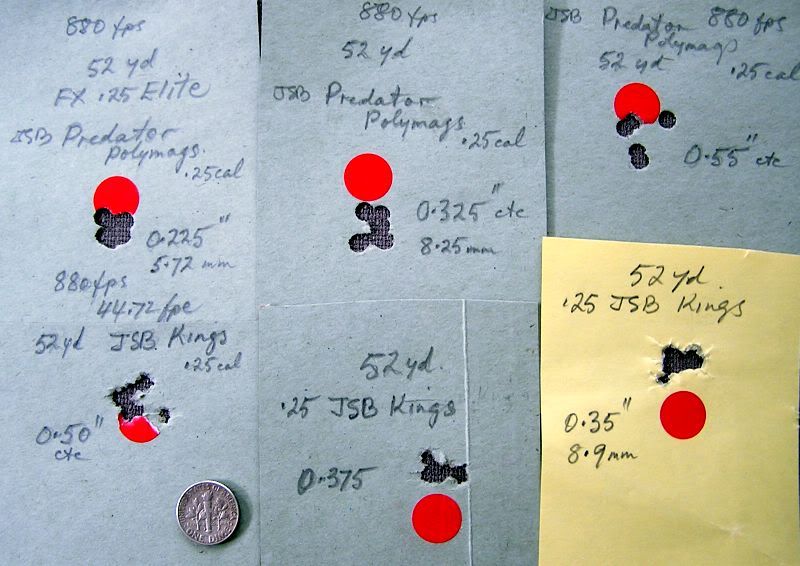

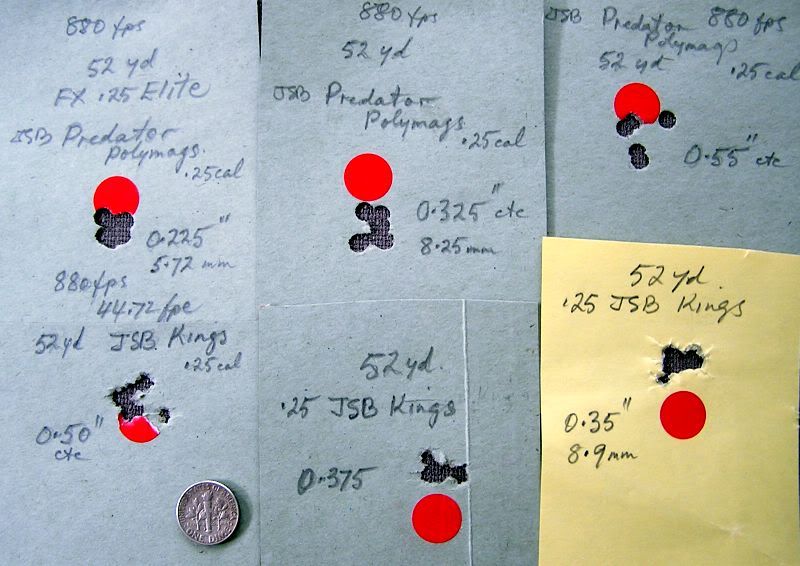

My ST .25 cal barrel results in spin rate of 1:75" approx with 25.4 gr JSB Kings. This, together with the dominant drag stabilization of the diabolo pellet, is apparently quite sufficient to produce match accuracy as shown these target groups with two very different pellet types; and in this SM video (below) which I took over 50 yards.

Groups shot with JSB Kings at initial pellet spin rate of 1:75":

The beautifully stable flight over 50 yards from the initial 1:75" spin rate.

http://vidmg.photobucket.com/albums/v392/Kyogle/FX25STElite3JSBKings51ydspigsilhouetteJan2012wmvforEmail_zpsacc2791c.mp4

I remember encouraging Dan Brown to do these tests before I had received my first ST barrel.

http://www.network54.com/Forum/79537/thread/1277076002

It is also a misconception that diabolo pellets will "tumble" when shot too slowly or from a true smooth bore without rifling. Neither do they suffer from precession, or induced spiral flight, as they are not gyroscopes. Here is an example from a boy's cheap post-war rifle. They no doubt do yaw however.

Smooth bore Stella; pellet stability established through drag. Pellets have C of G in front of CP. They will not "tumble".

http://www.network54.com/Forum/79537/message/1254311466

A further word about spin rate and its acceleration relative to units of distance traveled ( despite slowing in actual revolutions per unit of time s ).

Spin rate change to 200 yd

http://www.network54.com/Forum/79537/thread/1281248469

Stability Factors well in excess of 2 and even 3 are tolerated by diabolos with C of G ahead of C of wind pressure simply because they are predominantly drag stabilized. So, much of the data relevant to bullets again does not slavishly apply to our diabolo pellets.

Kind regards to all, Harry.

My ST .22 barrel has these stats:

Actual rifling twist rate is 1:16" given to me in conversation with Fredrik.

My marked pellet dual and triple screen tests showed effective spin rates of 1:64" with JSB Exact 15.9 gr; 1:44" with 21 gr Baracuda Match; and 1: 90" inch with the more bullet-like 25.4 gr JSB Monsters which it also shoots very well.

Quote me:..."The actual spin rate is approx average 1:64 inches when averaged from two tests through 16" separated screens and three tests through 8" separated screens.

Raw data at 16" screen gap was 90 degrees rotation and 91 degrees rotation = 1:64" and 1:63.3" spin rate respectively.

Raw data for 8" screen gap was 44 d, 44 d, 47 degrees rotation for 1:65.4", 1:65.4", 1:61.3" spin rate respectively. ... " Unquote.

My .22 barrel is a later iteration than Dan Brown's which he measured similarly to have a 1:162" initial spin rate. (Dan shot a sub 1/2" 100 yard 5 shot group with that barrel).

When in conversation with Fredrik I relayed my findings, He was most surprised and spent the whole next weekend doing the tests. He subsequently phoned to agree with my findings and we discussed the possibility of changes to the rifling to perhaps get a better correlation between barrel twist rate and pellet spin rate. But we agreed that the accuracy of the barrels as they stood would hardly warrant a change.

It would appear that one reason for differing results is that different velocities and different pellet weights produce different pellet momentum. Thus when impacting the rifling in the last couple of inches of an ST barrel the degree of stripping is impulse affected..

In any case the pellets never actually engage the rifling and so show only five "flats": with no grooves from the barrel's lands.

A shot Baracuda pellet showing the "flats" from skidding through the 1:16" barrel twist rate and emerging in this case with a spin rate of 1:44":

My ST .25 cal barrel results in spin rate of 1:75" approx with 25.4 gr JSB Kings. This, together with the dominant drag stabilization of the diabolo pellet, is apparently quite sufficient to produce match accuracy as shown these target groups with two very different pellet types; and in this SM video (below) which I took over 50 yards.

Groups shot with JSB Kings at initial pellet spin rate of 1:75":

The beautifully stable flight over 50 yards from the initial 1:75" spin rate.

http://vidmg.photobucket.com/albums/v392/Kyogle/FX25STElite3JSBKings51ydspigsilhouetteJan2012wmvforEmail_zpsacc2791c.mp4

I remember encouraging Dan Brown to do these tests before I had received my first ST barrel.

http://www.network54.com/Forum/79537/thread/1277076002

It is also a misconception that diabolo pellets will "tumble" when shot too slowly or from a true smooth bore without rifling. Neither do they suffer from precession, or induced spiral flight, as they are not gyroscopes. Here is an example from a boy's cheap post-war rifle. They no doubt do yaw however.

Smooth bore Stella; pellet stability established through drag. Pellets have C of G in front of CP. They will not "tumble".

http://www.network54.com/Forum/79537/message/1254311466

A further word about spin rate and its acceleration relative to units of distance traveled ( despite slowing in actual revolutions per unit of time s ).

Spin rate change to 200 yd

http://www.network54.com/Forum/79537/thread/1281248469

Stability Factors well in excess of 2 and even 3 are tolerated by diabolos with C of G ahead of C of wind pressure simply because they are predominantly drag stabilized. So, much of the data relevant to bullets again does not slavishly apply to our diabolo pellets.

Kind regards to all, Harry.

Upvote 0

AZ in your various mentions of 'Groove Marks' you seem to be implying that gross deformations to the projectiles "inherent roundness" (cant think of a better term ) will actually enhance its BC ?

The modern Diablo pellet is not in any way comparable to a Badminton Shuttlecock.

The modern Diablo pellet is not in any way comparable to a Badminton Shuttlecock.

Upvote 0

My comment dismissing diabolo pellets as gyroscopes was meant to be in the context of smooth bores that don't induce pellet spin; no spin therefore no gyroscope, precession, nutation or possibility of spiral flight. I have modified the quote (...) to improve the clarity:

Quote me, "It is also a misconception that diabolo pellets will “tumble” when shot too slowly ( or from a true smooth bore without rifling. Neither,(in the latter), do they suffer from precession, or induced spiral flight, as they (don't spin and therefore) are not gyroscopes."

or from a true smooth bore without rifling. Neither,(in the latter), do they suffer from precession, or induced spiral flight, as they (don't spin and therefore) are not gyroscopes."

I take your point regarding flight from smooth bores at velocities above those for which such bores were originally used in AG.

..." and will not shoot good at all when 800-900 fps and above…The higher the velocity the more inconsistencies and the more flyers I got."..

Though spin is not induced by the bore, the pellet will pick up random rotations in flight from changes of orientation and yaw interacting with the airflow and ambient conditions. Any such anomalies are bound to be exacerbated by projection at higher velocities.

To clarify the nature of the ST barrels' rifling: The rifling was not designed to eliminate the "buttering" effect you mention AZ. It is in fact quite conventional in its nature. Though difficult to do, and requiring some pellet rotation in process when doing it by hand, it is possible to push a pellet through an ST barrel such that it mirrors the lands and grooves but a pellet cannot be shot through an ST barrel to even come close to having its spin rate duplicate the bore twist rate..

Though a little fuzzy this pic I have taken shows the conventional aspect of the ST rifling which is quite different to the "Skidded" flats of the shot pellets:

Hence my statement that: "in any case the pellets never actually engage the rifling and so show only five “flats”: with no grooves from the barrel’s lands.”.

Regardless of not being in accord with conventional tables for bullet stability computation based on length, twist rate etc., the pellets do travel to extreme ranges in a most stable fashion.

This .25 JSB King pellet was shot into the dirt at 183 yards and dramatically shows that it arrived point on.

And another at the same range shot into tree bark with same attitude:

And into hardwood:

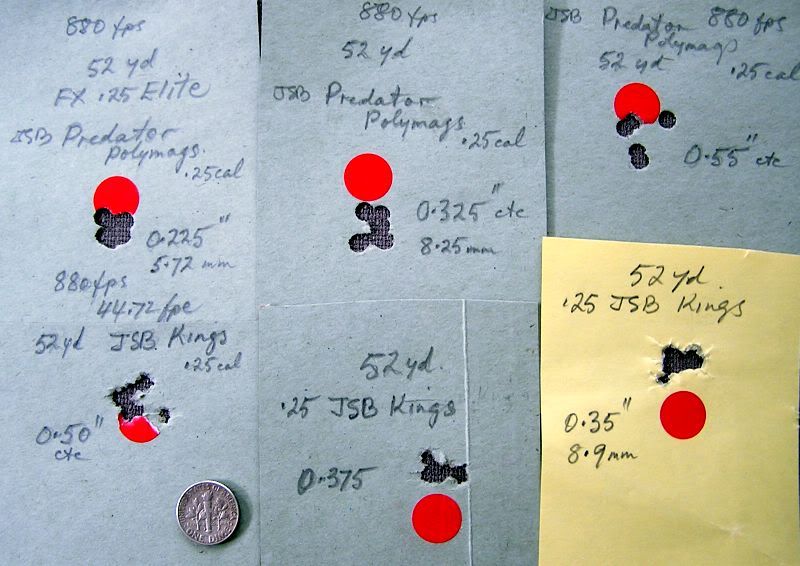

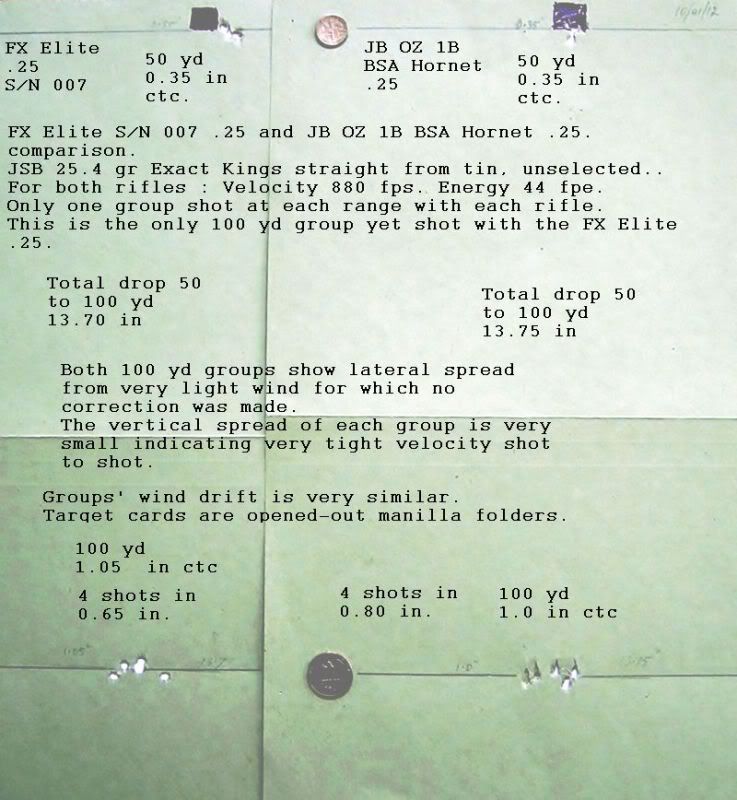

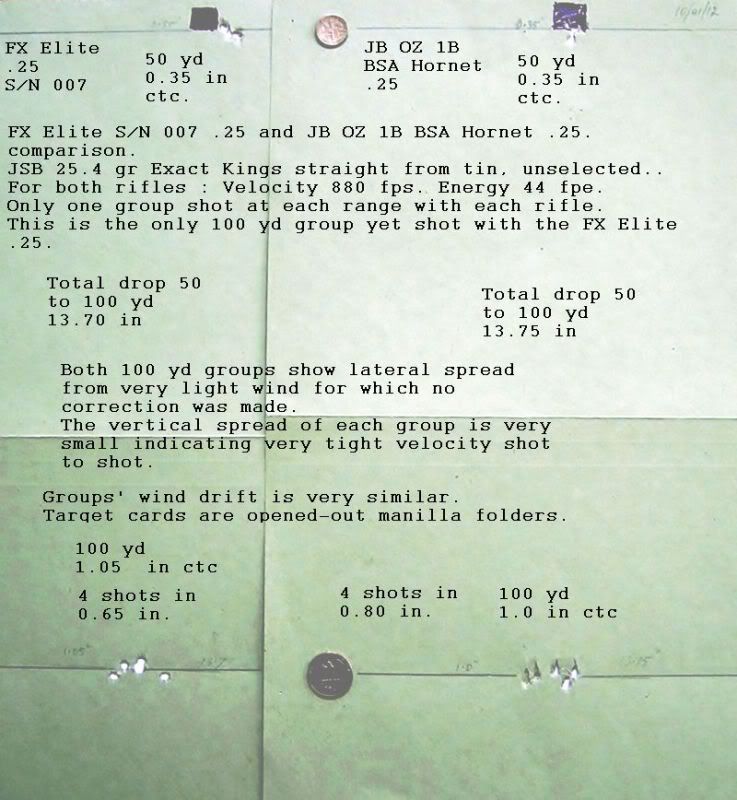

This is the 5 shot group at the same 183 yd range indicating exceptional precision of 1.11 moa 2.12 inches ctc shot in some light breeze:

Recall the initial spin rate was approx 1:75 inches from a 1:16 inch barrel twist.

In respect of the possible Ballistic Coefficient advantage or disadvantage associated with the profile of an ST barrel shot pellet, I offer this study findings:

Quote me: " A velocity decay test and computed ballistic coefficient were undertaken with 5 of JSB King pellets being shot over a chronograph at each distance of 18 inches and then at 55 yards at average velocity of 900 fps +/- 3 fps ST barrel; and 898.2 fps +/- 2.5 fps for the conventional BSA barrel at 18 inches.

The average velocities at 55 yards were 746 fps ST Elite barrel, 31.4 fpe, BC 0.0361 ( 0.0313 corrected to sea level ); and 760 fps, 32.6 fpe, BC 0.0407 ( 0.0352 corrected for sea level ) for the BSA Hornet. (Steve Woodwards BC calculator used).

This result indicates what appears to be a significant difference between the two barrels when the initial velocity of this pellet is increased to Mach 0.80. ... It is not in accord with the popular conjecture that the smoother rifling engravings on the ST barrel's projected pellets should necessarily automatically translate to an air resistance advantage in flight when compared to the engravings incurred from a conventionally rifled barrel. One school of reasoning in PB bullet ballistics is that the rifling engraving is of little consequence to air resistance as the boundary layer acts to moderate the possible influence."

That has been repeated with other pellets with similar results with lower BC reflecting higher Drag Coefficient for the ST shots.

However, strangely, this following study involving 5 shot groups at both 50 and 100 yards did not reflect the BC difference with any significant difference in pellet drop: Details of experimental design are outlined on the picture. Smooth Twist barrel on FX Elite to the left; conventional barreled BSA to the right: POA was the little black square for each range to indicate drop at 100 yards after sighting in at 50 yards.

It is always difficult to respond to subtle technical subjects in an abbreviated simple manner. Readers please forgive the extent of my replies which hopefully do explain my points of view with little ambiguity.

The fact that most of you are half a world spin away from me on this precessing gyroscopic planet Earth makes response-timing rather somewhat offset :-( ........... I hope AZ and others appreciate the time given here in sharing my first hand field studies. ...... Best regards, Harry. (Fishing for accuracy Brownie points ha ha).

Quote me, "It is also a misconception that diabolo pellets will “tumble” when shot too slowly (

I take your point regarding flight from smooth bores at velocities above those for which such bores were originally used in AG.

..." and will not shoot good at all when 800-900 fps and above…The higher the velocity the more inconsistencies and the more flyers I got."..

Though spin is not induced by the bore, the pellet will pick up random rotations in flight from changes of orientation and yaw interacting with the airflow and ambient conditions. Any such anomalies are bound to be exacerbated by projection at higher velocities.

To clarify the nature of the ST barrels' rifling: The rifling was not designed to eliminate the "buttering" effect you mention AZ. It is in fact quite conventional in its nature. Though difficult to do, and requiring some pellet rotation in process when doing it by hand, it is possible to push a pellet through an ST barrel such that it mirrors the lands and grooves but a pellet cannot be shot through an ST barrel to even come close to having its spin rate duplicate the bore twist rate..

Though a little fuzzy this pic I have taken shows the conventional aspect of the ST rifling which is quite different to the "Skidded" flats of the shot pellets:

Hence my statement that: "in any case the pellets never actually engage the rifling and so show only five “flats”: with no grooves from the barrel’s lands.”.

Regardless of not being in accord with conventional tables for bullet stability computation based on length, twist rate etc., the pellets do travel to extreme ranges in a most stable fashion.

This .25 JSB King pellet was shot into the dirt at 183 yards and dramatically shows that it arrived point on.

And another at the same range shot into tree bark with same attitude:

And into hardwood:

This is the 5 shot group at the same 183 yd range indicating exceptional precision of 1.11 moa 2.12 inches ctc shot in some light breeze:

Recall the initial spin rate was approx 1:75 inches from a 1:16 inch barrel twist.

In respect of the possible Ballistic Coefficient advantage or disadvantage associated with the profile of an ST barrel shot pellet, I offer this study findings:

Quote me: " A velocity decay test and computed ballistic coefficient were undertaken with 5 of JSB King pellets being shot over a chronograph at each distance of 18 inches and then at 55 yards at average velocity of 900 fps +/- 3 fps ST barrel; and 898.2 fps +/- 2.5 fps for the conventional BSA barrel at 18 inches.

The average velocities at 55 yards were 746 fps ST Elite barrel, 31.4 fpe, BC 0.0361 ( 0.0313 corrected to sea level ); and 760 fps, 32.6 fpe, BC 0.0407 ( 0.0352 corrected for sea level ) for the BSA Hornet. (Steve Woodwards BC calculator used).

This result indicates what appears to be a significant difference between the two barrels when the initial velocity of this pellet is increased to Mach 0.80. ... It is not in accord with the popular conjecture that the smoother rifling engravings on the ST barrel's projected pellets should necessarily automatically translate to an air resistance advantage in flight when compared to the engravings incurred from a conventionally rifled barrel. One school of reasoning in PB bullet ballistics is that the rifling engraving is of little consequence to air resistance as the boundary layer acts to moderate the possible influence."

That has been repeated with other pellets with similar results with lower BC reflecting higher Drag Coefficient for the ST shots.

However, strangely, this following study involving 5 shot groups at both 50 and 100 yards did not reflect the BC difference with any significant difference in pellet drop: Details of experimental design are outlined on the picture. Smooth Twist barrel on FX Elite to the left; conventional barreled BSA to the right: POA was the little black square for each range to indicate drop at 100 yards after sighting in at 50 yards.

It is always difficult to respond to subtle technical subjects in an abbreviated simple manner. Readers please forgive the extent of my replies which hopefully do explain my points of view with little ambiguity.

The fact that most of you are half a world spin away from me on this precessing gyroscopic planet Earth makes response-timing rather somewhat offset :-( ........... I hope AZ and others appreciate the time given here in sharing my first hand field studies. ...... Best regards, Harry. (Fishing for accuracy Brownie points ha ha).

Upvote 0

AZ, your definitions are accurate. No problem there.

If you read the quote literally and in two parts , "“it is possible to push a pellet through an ST barrel such that it mirrors the lands and grooves ... " means just what it states viz., that with care a pellet can be pushed (slowly and with correlating rotation) through the rifled section such that the rifling lands engrave the pellet with grooves and the rifling grooves leave "lands" on the pellet such that the pellet surface is then a mirror image of the barrel's rifling. Take time out here to again look at the photo I showed of the ST rifling.

I have not shown a pic of a pellet having been pushed through the rifling in this manner, but you can visualize a pellet with engraved matching rifling marks, grooves where the rifling has engraved them and "lands" by whatever name you choose, which have filled the barrel grooves. Just imagine it. That is how the pellet would be if it corresponded to the rifling when shot - but it does not!

Now the rest of the quote, “ ... but a pellet cannot be shot through an ST barrel to even come close to having its spin rate duplicate the bore twist rate" . ... and the next sentence reads, " ...this pic I have taken shows the conventional aspect of the ST rifling which is quite different to the “Skidded” flats of the shot pellets":.. here the supporting two pics show clearly that the shot pellet's surface in no way matches the rifling of the barrel.;

You seem to disregard the pic of the actual rifling and somehow want to substitute one with hexagonal rifling to match my pellet pic. There is no "..rifled bore has 6 sides that are angled 60 degrees and this section of the barrel ...". Look again at the actual bore pic which clearly shows a barrel that is rather conventional with five lands and five grooves.

Late edit to show the aspect of the lands when hit by the now high velocity pellet as it strips through thus creating the flat skid engraving on the pellet surface whilst picking up a spin rate of approximately just 1/5 to 1/3 of the barrel twist rate depending upon pellet weight and velocity (ie., momentum).

So yes, you do understand me in that I have said, more than once in this exchange, "... that the pellet as it leaves the barrel is not spinning even close to the spin that the twist ratio of the last section of the barrel should’ve put on the pellet". You have that right!

And you have this right too, "I don’t understand how this could be possible unless the pellet is SKIDDING inside the rifling and exits spinning at less RPM’s ... ".... That is exactly what happens AZ. And if you go back to my early response you will read again of the actual spin rates that Dan Brown, myself and the FX boss Fredrik independently assessed with different barrel iterations (mine was the 16th, Fredrik's the 18th and Dan's a much earlier model).

But then having sorted that out you still want to inject some other irrelevant hexagonal (six sides) rifling into the equation to match just five corners on the actual skidding pellet, " .. If this were the case, then we wouldn’t see those sharp edges on the hexagonal pattern as shown on that photo, those edges would be marred..".

"The rifled bore has 6 sides that are angled 60 degrees ... ". No it hasn't. It has five lands and five grooves as in the pic of it.

" according to the photo on your 7:16 AM reply, the rifling is a full hexagonal pattern and the spin will be whatever the twist ratio the barrel maker decided to use….I think that we will all agree to this point. ". No we can't agree as there is no hexagonal pattern in the rifling, it is of five lands and five grooves as shown in the pic of the rifling. The pellet has five flats as the result of skidding through that rifling without fully engaging it as I stated at the beginning ; and the spin rate is not even close to the 1:16 ratio of the makers rifling.

As you now seem to agree that our best pellets are in fact predominantly drag stabilized and have no need to fully conform to powder rifle stabilization factors presented in your initial post, I intend to leave that there.

Nor apparently do the polycarbonate Predator .25 Polymags you mention require better spin rates to stabilize if judged by the 5 shot targets I posted. These were as small as 0.225" ctc at 50 yards when shot from, and skidding-through, ST rifling resulting in a spin rate of just 1:75"'

Bedtime for this old man so I again send my regards and a goodnight kiss ... Harry.

Late edit to put in a pic with lines to indicate the probably extent of the "skid" pellet marks engraved origins.

If you read the quote literally and in two parts , "“it is possible to push a pellet through an ST barrel such that it mirrors the lands and grooves ... " means just what it states viz., that with care a pellet can be pushed (slowly and with correlating rotation) through the rifled section such that the rifling lands engrave the pellet with grooves and the rifling grooves leave "lands" on the pellet such that the pellet surface is then a mirror image of the barrel's rifling. Take time out here to again look at the photo I showed of the ST rifling.

I have not shown a pic of a pellet having been pushed through the rifling in this manner, but you can visualize a pellet with engraved matching rifling marks, grooves where the rifling has engraved them and "lands" by whatever name you choose, which have filled the barrel grooves. Just imagine it. That is how the pellet would be if it corresponded to the rifling when shot - but it does not!

Now the rest of the quote, “ ... but a pellet cannot be shot through an ST barrel to even come close to having its spin rate duplicate the bore twist rate" . ... and the next sentence reads, " ...this pic I have taken shows the conventional aspect of the ST rifling which is quite different to the “Skidded” flats of the shot pellets":.. here the supporting two pics show clearly that the shot pellet's surface in no way matches the rifling of the barrel.;

You seem to disregard the pic of the actual rifling and somehow want to substitute one with hexagonal rifling to match my pellet pic. There is no "..rifled bore has 6 sides that are angled 60 degrees and this section of the barrel ...". Look again at the actual bore pic which clearly shows a barrel that is rather conventional with five lands and five grooves.

Late edit to show the aspect of the lands when hit by the now high velocity pellet as it strips through thus creating the flat skid engraving on the pellet surface whilst picking up a spin rate of approximately just 1/5 to 1/3 of the barrel twist rate depending upon pellet weight and velocity (ie., momentum).

So yes, you do understand me in that I have said, more than once in this exchange, "... that the pellet as it leaves the barrel is not spinning even close to the spin that the twist ratio of the last section of the barrel should’ve put on the pellet". You have that right!

And you have this right too, "I don’t understand how this could be possible unless the pellet is SKIDDING inside the rifling and exits spinning at less RPM’s ... ".... That is exactly what happens AZ. And if you go back to my early response you will read again of the actual spin rates that Dan Brown, myself and the FX boss Fredrik independently assessed with different barrel iterations (mine was the 16th, Fredrik's the 18th and Dan's a much earlier model).

But then having sorted that out you still want to inject some other irrelevant hexagonal (six sides) rifling into the equation to match just five corners on the actual skidding pellet, " .. If this were the case, then we wouldn’t see those sharp edges on the hexagonal pattern as shown on that photo, those edges would be marred..".

"The rifled bore has 6 sides that are angled 60 degrees ... ". No it hasn't. It has five lands and five grooves as in the pic of it.

" according to the photo on your 7:16 AM reply, the rifling is a full hexagonal pattern and the spin will be whatever the twist ratio the barrel maker decided to use….I think that we will all agree to this point. ". No we can't agree as there is no hexagonal pattern in the rifling, it is of five lands and five grooves as shown in the pic of the rifling. The pellet has five flats as the result of skidding through that rifling without fully engaging it as I stated at the beginning ; and the spin rate is not even close to the 1:16 ratio of the makers rifling.

As you now seem to agree that our best pellets are in fact predominantly drag stabilized and have no need to fully conform to powder rifle stabilization factors presented in your initial post, I intend to leave that there.

Nor apparently do the polycarbonate Predator .25 Polymags you mention require better spin rates to stabilize if judged by the 5 shot targets I posted. These were as small as 0.225" ctc at 50 yards when shot from, and skidding-through, ST rifling resulting in a spin rate of just 1:75"'

Bedtime for this old man so I again send my regards and a goodnight kiss ... Harry.

Late edit to put in a pic with lines to indicate the probably extent of the "skid" pellet marks engraved origins.

Upvote 0

I just read through this whole dang interesting thread. You guys are talking a little above my head on some of this but the wealth of information and experimentation is really appreciated! Great conversation, and I appreciate you bringing it down a notch so we all have a chance at understanding. It's thinking like yours that brings this sport to the next level.

+'s for both of you!

Tom

+'s for both of you!

Tom

Upvote 0

AZ I'm not sure if you caught my very late edit showing the pic of the bore with yellow lines indicating my conception of the apparent width of each barrel land as it would present to the then high velocity pellet. Such apparent width of the lands would take into account their offset over the now measured approx 1.25" of rifling.

A word about the manufacture of the ST rifling. The last 2.5 inches of the barrel are turned down to much less diameter approx 9 mm. This enables the rifling to be impressed from the outside, of the turned-down section, by the industrial machine used. The imprint of the industrial die is much sharper on the outside of the barrel than is the rifling raised on the inside.

Pic shown of the barrel with the covering sleeve removed. Here it is installed on my RWS Excalibre/ FX Tarantula:

The reason for Fredrik developing Ben Taylor's original machine idea for making these barrels was not to save manufacturing cost. It was to gain complete control over quality of barrels. As others have found, RAW for example, it has become very expensive to have to discard 10s of thousands of $ worth of barrels that do not meet the standards shooters are demanding. The barrel makers, LW for example, will not take back rejects. So Fredrik made the decision to explore the new way of making what amounts to the old paradox method of having a smooth bore with rifling only in the muzzle section. This has been very costly to FX.

Just getting the smooth bore section as brilliantly concentric and perfect as it is mustn't be a cheap operation. Then every barrel is hand straightened by Fredrik! My barrels, when held to the light show a series of absolutely concentric reflected rings, the indication of a truly straight tube.

Then there has been the ongoing R&D on the format of that rifling. As I indicated, my .22 barrel was the 16th iteration and it has moved on from there. ... So it was not a cost cutting measure. I suspect it will always be expensive. The machines used would be costly and requiring constant maintenance and skilled adjustment.

Much else could be written but it is apparently a misconception that the endeavor was simply a cost cutting measure.

As we are pretty much on the same page now AZ, I too will leave your post unless directly addressed with questions.

Thanks for tolerating my extensive responses. As I wrote before, it is quite difficult sometimes to make a simple response which is accurate. We have satisfactorily worked through this one - I think..... Best regards, Harry.

A word about the manufacture of the ST rifling. The last 2.5 inches of the barrel are turned down to much less diameter approx 9 mm. This enables the rifling to be impressed from the outside, of the turned-down section, by the industrial machine used. The imprint of the industrial die is much sharper on the outside of the barrel than is the rifling raised on the inside.

Pic shown of the barrel with the covering sleeve removed. Here it is installed on my RWS Excalibre/ FX Tarantula:

The reason for Fredrik developing Ben Taylor's original machine idea for making these barrels was not to save manufacturing cost. It was to gain complete control over quality of barrels. As others have found, RAW for example, it has become very expensive to have to discard 10s of thousands of $ worth of barrels that do not meet the standards shooters are demanding. The barrel makers, LW for example, will not take back rejects. So Fredrik made the decision to explore the new way of making what amounts to the old paradox method of having a smooth bore with rifling only in the muzzle section. This has been very costly to FX.

Just getting the smooth bore section as brilliantly concentric and perfect as it is mustn't be a cheap operation. Then every barrel is hand straightened by Fredrik! My barrels, when held to the light show a series of absolutely concentric reflected rings, the indication of a truly straight tube.

Then there has been the ongoing R&D on the format of that rifling. As I indicated, my .22 barrel was the 16th iteration and it has moved on from there. ... So it was not a cost cutting measure. I suspect it will always be expensive. The machines used would be costly and requiring constant maintenance and skilled adjustment.

Much else could be written but it is apparently a misconception that the endeavor was simply a cost cutting measure.

As we are pretty much on the same page now AZ, I too will leave your post unless directly addressed with questions.

Thanks for tolerating my extensive responses. As I wrote before, it is quite difficult sometimes to make a simple response which is accurate. We have satisfactorily worked through this one - I think..... Best regards, Harry.

Upvote 0

I am enjoying this thread very much! Thanks AZ for starting this. And thank you Harry for your contributions. I am new to high end PCP guns. Been playing with (tuning and moding) a .22 Marauder for a while. I have a RAW hm1000x .25 due to arrive next week and have been studying everything I can about air gun Accuracy. I believe I have a bit clearer understanding of the whole velocity pellet weight and twist rate relationship now. And a much greater appreciation for the design and tuning that manufacturers must go through to meet the accuracy demands of shooters like myself. I really enjoy pushing the limits of long range target shooting. That's one of the main reasons I chose the RAW. I hope I chose well. While I like tweeking my guns for improved performance you guys have me rethinking playing with the adjustments of my RAW. I could probably only make it shoot worse.

Thanks again!

Thanks again!

Upvote 0

Interesting AZ. Would the coating be the nickle boron that is popular for use in AR 15 parts such as upper receivers, bolt carrier groups and even inside and out of barrels? I have seen that used inside those barrels though I don't know how it may effect accuracy. It is very self lubricating and guns can even be run dry safely or so it is claimed.

Upvote 0

A couple of points to make RE: FX SmoothTwist barrels -

Harry's photo (posted at 6:38) is excellent ! & I would draw attention to the progressive depth of the external 'pressing' or swagging - ie. from right to left in that photo. This outer swagging introduces the 'gently rounded' internal raised lands that increase very gradually in height towards the muzzle.

Fredrik originally tried this system using conventional smooth bore barrel blanks - he found the variation in wall thickness for any given batch to be too great (not an issue, perhaps, for a button rifling machine, but not good at all for the Ben Taylor machines).

Therefore he now uses VERY expensive 'blanks' that have the required 'confirmation' - these are not provided or produced by an established Barrel Maker.

Harry's photo (posted at 6:38) is excellent ! & I would draw attention to the progressive depth of the external 'pressing' or swagging - ie. from right to left in that photo. This outer swagging introduces the 'gently rounded' internal raised lands that increase very gradually in height towards the muzzle.

Fredrik originally tried this system using conventional smooth bore barrel blanks - he found the variation in wall thickness for any given batch to be too great (not an issue, perhaps, for a button rifling machine, but not good at all for the Ben Taylor machines).

Therefore he now uses VERY expensive 'blanks' that have the required 'confirmation' - these are not provided or produced by an established Barrel Maker.

Upvote 0