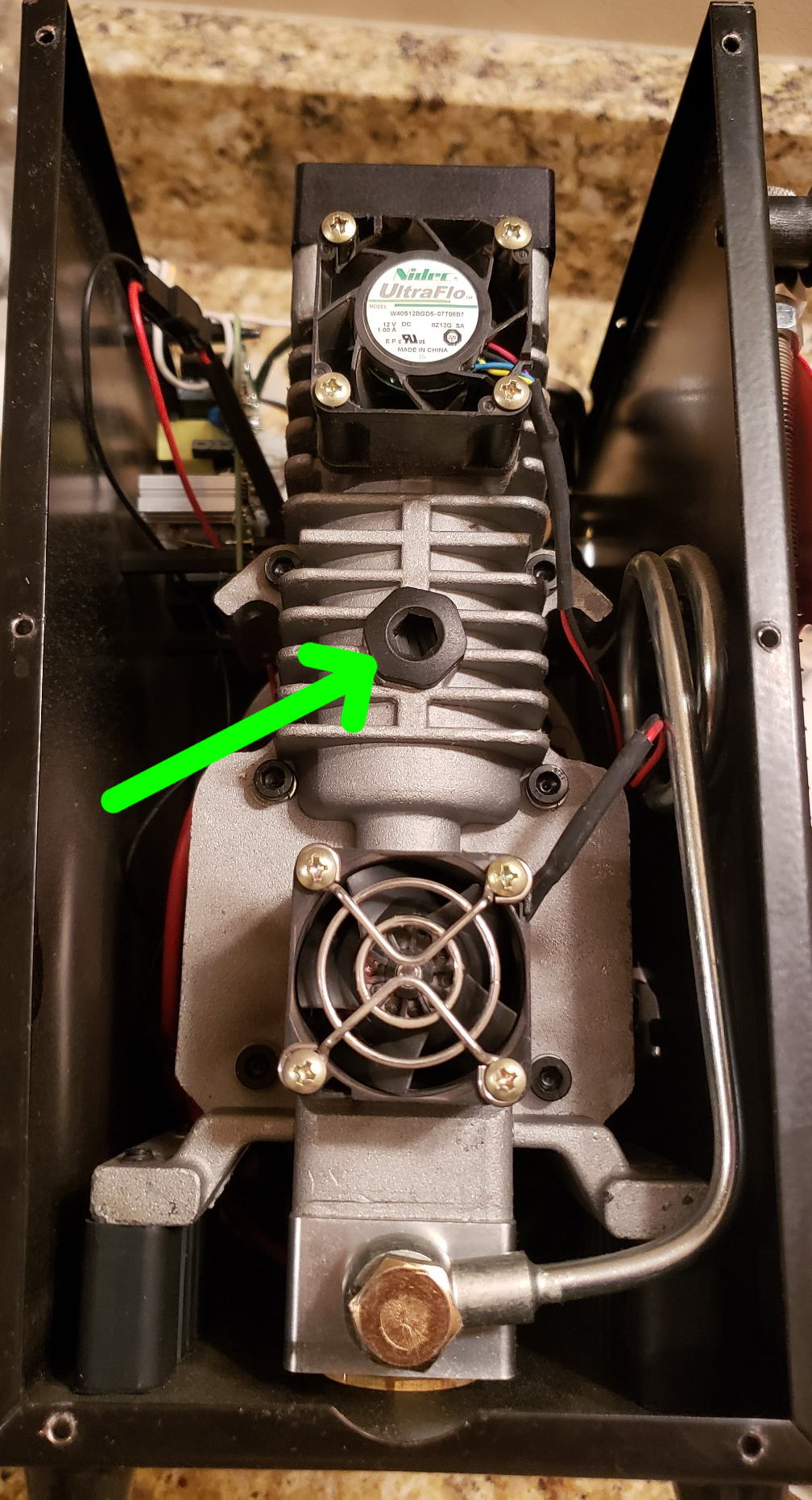

I am pretty sure that the black filler plug on the cylinder is for adding grease. The manual refers to part #51 but on the diagram that is an O-Ring. The Manual calls it the oil drain plug and the part number for the black cover is # 48. My owner's manual says to grease it every 100 hours, some apparently read 50 hours and some say it never needs grease. I am going with a small amount of grease at maybe 30 hours. Hopefully it will be easy to figure out. The instructions say to turn the motor on and off until the high pressure rod #71 is exposed and to add the grease there with a syringe. There is no part labeled High Pressure Rod in the diagram.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Greasing the piston on a GX CS3 / CS2 compressor

- Thread starter Geezerhood

- Start date

Update. I found a Target Forge video on YouTube showing how to grease the GX upper cylinder as well as the lower High Pressure Rod,

Which is not mentioned in the manual but recommended by Target Forge vs just lubing the high pressure rod. What is the recommended run time for lubricating the top end - I didn't hear him state that?

On greasing only the high pressure rod per the owner's manual, it took about 30 tries to get the piston up high, exposing the rod but I finally got it. I can see some grease on that rod already so I didn't add any more - just moved what was hanging there but not on the rod so it was touching the rod. Using a tool to rotate the motor as shown in the video looks to be the way to go to get it aligned.

Piston blocking the opening is the way it stops most of the time.

Rod showing took about 30 on off cycles.

Which is not mentioned in the manual but recommended by Target Forge vs just lubing the high pressure rod. What is the recommended run time for lubricating the top end - I didn't hear him state that?

On greasing only the high pressure rod per the owner's manual, it took about 30 tries to get the piston up high, exposing the rod but I finally got it. I can see some grease on that rod already so I didn't add any more - just moved what was hanging there but not on the rod so it was touching the rod. Using a tool to rotate the motor as shown in the video looks to be the way to go to get it aligned.

Piston blocking the opening is the way it stops most of the time.

Rod showing took about 30 on off cycles.

Last edited:

Upvote 0

I would like to find some grease that will work as well as or better than the original grease, on this piston / cylinder that doesn't cost a fortune. I am guessing that the grease they use on it from the factory isn't anything that can't be found among all the various grease options out there. They call it a "vegetable" grease. Doesn't sound to high tech to me.

I would assume it needs to have a fairly low flash point so it won't combust under pressure, good lubricative qualities ( O-Ring silicone grease isn't that great of a lubricant) won't deteriorate the plastic piston rings / seals and holds up to a moderate amount of heat, but not like inside a combustion engine. The seal on the piston is is synthetic and rides on metal so it doesn't have to some magical formula. I don't want to spend $20 in grease that costs $1 / cc when it comes time to rebuild the two pistons.

What options have any of you tried?

I would assume it needs to have a fairly low flash point so it won't combust under pressure, good lubricative qualities ( O-Ring silicone grease isn't that great of a lubricant) won't deteriorate the plastic piston rings / seals and holds up to a moderate amount of heat, but not like inside a combustion engine. The seal on the piston is is synthetic and rides on metal so it doesn't have to some magical formula. I don't want to spend $20 in grease that costs $1 / cc when it comes time to rebuild the two pistons.

What options have any of you tried?

Upvote 0

EDIT: The product BSJ recommended - Multi-Purpose Synthetic Grease - Item 41150 was actually what GX said to use. I will leave the link below for anyone who might be thinking about using the Superlube Synthetic Grease - Multi-Purpose 21030 that caused problems when used with HPA.

This different grease than the one BSJ posted is known to "diesel" / explode / detonate / burn - Not sure what the correct term is - at high pressure in PCP guns. Link to such an incident with a hand pump.

The Superlube pure silicone grease that is highly recommended for use on PCP guns and O-Rings won't diesel but my understanding is that it is just a so-so lubricant compared to some other greases.

Last edited:

Upvote 0

Nope. Not the same stuff. What I linked to is exactly what GX told me to use.

NSF registered Food Grade lubricant, rated H1 for incidental food contact and meets former USDA (H1) guidelines. Super Lube Multi-Purpose Synthetic Grease is Kosher Certified.

NGLI Grade 2 Grease is NLGI GC-LB Certified.

NSF registered Food Grade lubricant, rated H1 for incidental food contact and meets former USDA (H1) guidelines. Super Lube Multi-Purpose Synthetic Grease is Kosher Certified.

NGLI Grade 2 Grease is NLGI GC-LB Certified.

| NGLI Grade | NLGI 2 |

| NLGI Classification | GC-LB* |

| Color | Translucent White |

| Temperature Range | -45°F to 450°F (-43°C to 232°C) |

Last edited:

Upvote 0

Nope. Not the same stuff. What I linked to is exactly what GX told me to use.

NSF registered Food Grade lubricant, rated H1 for incidental food contact and meets former USDA (H1) guidelines. Super Lube Multi-Purpose Synthetic Grease is Kosher Certified.

NGLI Grade 2 Grease is NLGI GC-LB Certified.

NGLI Grade NLGI 2 NLGI Classification GC-LB* Color Translucent White Temperature Range -45°F to 450°F (-43°C to 232°C)

Thanks for the correction and the additional information! Since GX recommended it, I will use it with confidence. If I had read the labeling more carefully on both products I would have seen the wording Multi-Purpose which they both have on the label, but with the addition of Food Grade and other stuff on the one they recommended to you, and of course a different product number. With so many Super Lube variations with very similar descriptions and names it can get confusing.

- Good Lube for GX Pistons: Super Lube Multi-Purpose Synthetic Grease with PTFE - Heavy duty, compatible with most other lubricants, dielectric, food grade, clean - Item 41150

- Not good for HPA use / Compressor Pistons: Super Lube Synthetic Grease - Multi-Purpose lubricant with PTFE Item 21030

Last edited:

Upvote 0

Target forge sells the grease for them. It is expensive but at least you know what you got. It isn’t necessary to use it that often either which helps price wise. The target forge video also explains using a screw (forget what exact size) in the motor (I think) to manually turn the piston into the proper spot for servicing through that black port.

Upvote 0

From this older thread I found posted by bchannell on the CS3 lubrication, the actual grease that is used by GX - Renewable Lubricants 87501 Food Grade Multipurpose EP Grease. So, it looks like there are two factory recommended options for those wanting to get more than one rebuild's worth for $20. Buying 14 ounces at $10 / 10 ccs would cost you $414 not including shipping, so that is not an option. I will go with the 44 cents / 10 ccs rather than $10 + shipping. I am sure I will be rebuilding it several times over the years and can definitely find other uses for the grease as well.

- Renewable Lubricants 87501 Food Grade Multipurpose EP Grease $26 shipped from Ebay for 14 ounces (414 ccs!). (Apparently this is what ships with the GX compressors that had grease with them. Mine did not.)

- Super Lube 41150 Synthetic Multi-Purpose Grease - 14 ounces for $18 shipped from Amazon (Recommended to BSJ by GX.)

Last edited:

Upvote 0

If you want to turn the motor to get the piston rod at the right spot to grease it, remove the red cover and turn the electric motor using an alan key.

Upvote 0

If you want to turn the motor to get the piston rod at the right spot to grease it, remove the red cover and turn the electric motor using an alan key.

Thanks for the tip.

I would have to remove the flat cover and the entire faceplate on the CS3 to reach the motor to do that. Probably worth the time for lubing the high pressure piston, but the low pressure piston can just be pushed down to expose the cylinder walls.

Upvote 0

Took delivery yesterday of the Super Lube grease that the GX factory recommends. I lubed the low pressure cylinder walls after cleaning it well as shown in the various videos. It was easy to push the piston down for exposing the max amount of cylinder wall. After filling several guns I opened up the cylinder top and found that the grease had not changed color or texture, with no signs of combustion or new smells. I will check it again after an hour of use.

Upvote 0

An interesting bit of information - Before greasing the cylinder I tested the time to build pressure with a dead head on the short whip to 300 bar and again about 20 minutes of run time filling guns after greasing it . I will check the time to 300 bar again after it has been run two or 3 hours.

- Before - 82 seconds to hit 300 bar

- After 46 seconds

- 42 seconds to reach 250 bar.

Upvote 0

I just wanted to clear up a mistake in this thread. There is the misconception that Super Lube 41150 is recommended for the GX and that SL 21030 is not, which is wrong. They are both recommended as they are the same grease in different size packages. 41150 is a 14oz grease gun tube, while 21030 is a 3oz squeeze tube. Same stuff.

Upvote 0

21030 and 41150 are the same grease, just in different size packages. And since both are synthetic greases, not petroleum based, neither should cause any issues.EDIT: The product BSJ recommended - Multi-Purpose Synthetic Grease - Item 41150 was actually what GX said to use. I will leave the link below for anyone who might be thinking about using the Superlube Synthetic Grease - Multi-Purpose 21030 that caused problems when used with HPA.

This different grease than the one BSJ posted is known to "diesel" / explode / detonate / burn - Not sure what the correct term is - at high pressure in PCP guns. Link to such an incident with a hand pump.

The Superlube pure silicone grease that is highly recommended for use on PCP guns and O-Rings won't diesel but my understanding is that it is just a so-so lubricant compared to some other greases.

Upvote 0

Dear Geezehood,From this older thread I found posted by bchannell on the CS3 lubrication, the actual grease that is used by GX - Renewable Lubricants 87501 Food Grade Multipurpose EP Grease. So, it looks like there are two factory recommended options for those wanting to get more than one rebuild's worth for $20. Buying 14 ounces at $10 / 10 ccs would cost you $414 not including shipping, so that is not an option. I will go with the 44 cents / 10 ccs rather than $10 + shipping. I am sure I will be rebuilding it several times over the years and can definitely find other uses for the grease as well.

- Renewable Lubricants 87501 Food Grade Multipurpose EP Grease $26 shipped from Ebay for 14 ounces (414 ccs!). (Apparently this is what ships with the GX compressors that had grease with them. Mine did not.)

- Super Lube 41150 Synthetic Multi-Purpose Grease - 14 ounces for $18 shipped from Amazon (Recommended to BSJ by GX.)

i read carefully your post and i have just a question.

The above lubricants that you suggested, is possible to cover all moving parts ( cylinder, piston, bearing ) or specific part of GX Compressor???

Brgds

Dimitrios

Upvote 0

I've been happy with this so far for my GX-C3. A little thicker than Super Lube synthetic grease. Haven't done the wrist pin yet and debating this or the TF red moly.I would like to find some grease that will work as well as or better than the original grease, on this piston / cylinder that doesn't cost a fortune. I am guessing that the grease they use on it from the factory isn't anything that can't be found among all the various grease options out there. They call it a "vegetable" grease. Doesn't sound to high tech to me.

I would assume it needs to have a fairly low flash point so it won't combust under pressure, good lubricative qualities ( O-Ring silicone grease isn't that great of a lubricant) won't deteriorate the plastic piston rings / seals and holds up to a moderate amount of heat, but not like inside a combustion engine. The seal on the piston is is synthetic and rides on metal so it doesn't have to some magical formula. I don't want to spend $20 in grease that costs $1 / cc when it comes time to rebuild the two pistons.

What options have any of you tried?

Upvote 0

I would use a moly grease or any type of chassis lube on the wrist pin. Nothing special needed.

For the piston, I would LIGHTLY grease the cylinder wall, just a smear you can't actually see, using something like the Renewable Lubricants Food Grade grease recommended elsewhere. Then I would remove the piston and pack the large groove in it with grease which will largely stay below the piston seal and lube the walls. I'd smear some on the high pressure piston as well. Don't go overboard the grease groove will take care of most of the lubing. This type of lubing will easily get you through a good six months of moderate usage.

I'm not convinced that Super Lube Syn is a good fit for this. Not saying it won't work, just that I'm not sure of it. I've never actually seen or heard GX actually confirm any particular grease. Maybe I missed it and they did, but if they haven't approved the SL syn, then I'd pass. I DID contact SL and they said NO.

For the piston, I would LIGHTLY grease the cylinder wall, just a smear you can't actually see, using something like the Renewable Lubricants Food Grade grease recommended elsewhere. Then I would remove the piston and pack the large groove in it with grease which will largely stay below the piston seal and lube the walls. I'd smear some on the high pressure piston as well. Don't go overboard the grease groove will take care of most of the lubing. This type of lubing will easily get you through a good six months of moderate usage.

I'm not convinced that Super Lube Syn is a good fit for this. Not saying it won't work, just that I'm not sure of it. I've never actually seen or heard GX actually confirm any particular grease. Maybe I missed it and they did, but if they haven't approved the SL syn, then I'd pass. I DID contact SL and they said NO.

Upvote 0