I recently obtained a GX CS4 compressor direct from GX Pumps. They shipped quickly and it arrived a couple days later, well packaged and in good condition. It came with an assortment of tools, seals, rings, o-rings and springs, so looks like it has the parts needed for a complete rebuild, if needed. Based on other comments here, I flushed the cooling system with distilled water, drained it and refilled with a 50/50 pre-mix of Dexcool anti-freeze.

I ran a quick pressure test and was quite impressed with the speed at which it reached 400 BAR/5800 PSI! It's also very quiet, in fact, it's the quietest compressor I've ever owned and I've had quite a few over the years! Here's a quick video of the pressure test so you can here it running and see how fast it reached it's max capacity:

This is a 4 stage compressor running at a fairly low RPM, yet it makes nearly 10 BAR of pressure per stroke!

After ensuring everything was operating correctly, I filled my LSC SK-19's 580cc tank from 150 BAR to 250 BAR. This fill only took about a minute and the temerature of the compressor barely rose 4 degrees!

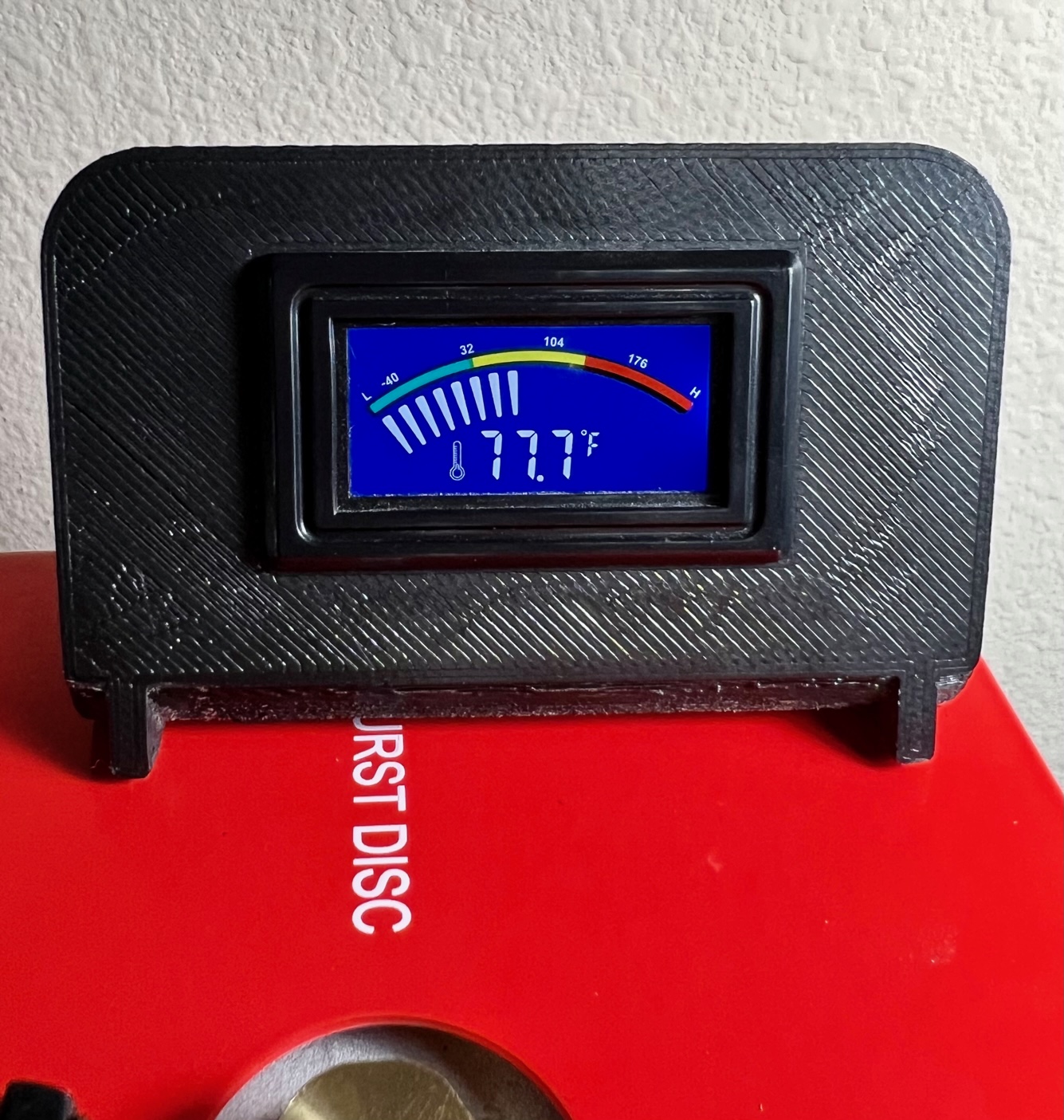

I did add a temperature Gauge, not that it's needed with how cool this compressor runs, but I just like seeing what's happening when filling!

Here are some pictures of what's under the hood:

This is the 4 stage compression chamber with cooling fins covering the entire outer cylinder.

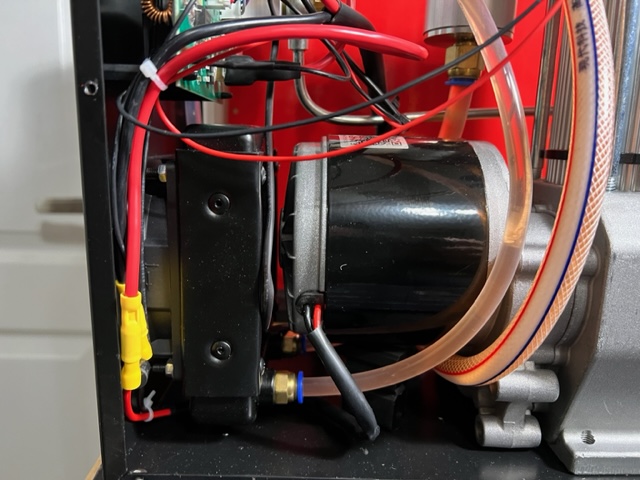

This is the 350X motor driving this beast and providing cooling air to the radiator.

The auto shutoff pressure gauge is really top notch! Much nicer than what comes on most lower end Chinese compressors. It has 2 set needles, I'm assuming one is a back-up in case thefirst doesn't work. I set it at 400 BAR. The second I set at my desired fill capacity. I will say I have found the gauge to be very accurate, much more so that most of the compressors I have owned.

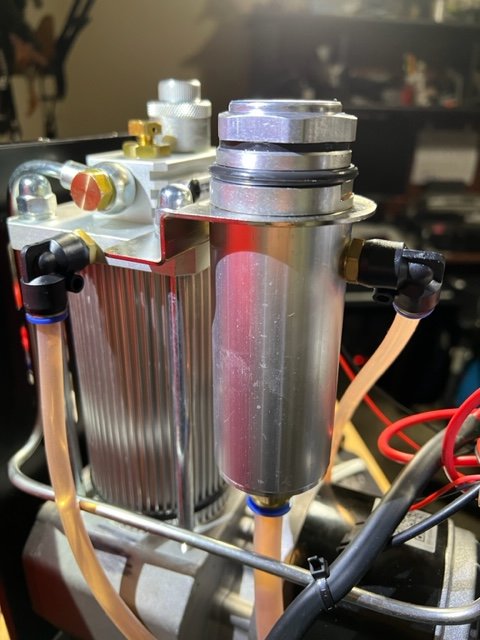

This is the resivoir for the cooling system. The whole self-contained system hold about 1 liter of water/coolant.

Here's another angle of the radiator.

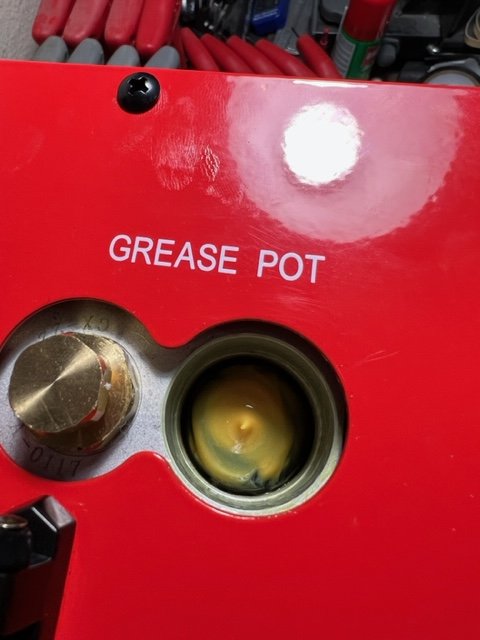

Here is the burst disk and grease pot, both these are accessible with the cover on the compressor.

The intake filts elbow was swing loose when I first opened it up, so I snugged it down so it wasn't loose. I'm not sure what the white part is attached to the head, but think it might be a temperature sensor.

Here is the main controller board.

When you remove the top of the grease pot, you can see the grease inside. The manual says to turn the knob on the top of the grease pot one full turn every 4-6 hours of operation. I need to contact GX and ask what type of greese to use, just to have some on hand if needed down the road.

The rest of the grease inside the grease pot.

This is how it looks with the cover on it, you can see the knob has arrows showing the direction to turn it when needed.

GX Claims this compressor has a 5 hour run cycle and is rated to fill up to a 6.8L air tank! Seeing that the temperature gauge barely moved when topping off the 580cc tank on the SK-19, I have no doubt that heat is not a huge problem with this compressor!

Amazon is selling these for $699.99 plus tax, but buying direct from GX Pumps, you can save over $100! They are currently on sale for $659.99, but by using the coupon code [GXPUMPS10OFF] it brings it to $593.99 shipped.

Thus far I am really quite impressed with the feature of this compressor for it's price point! It seems very solid and built to last. If interested, check out what they offer direct, they seem to alway have several different models in stock and on sale!

gxpumpofficial.com

gxpumpofficial.com

If you have any questions, please post them below and I'll try my best to answer them.

I ran a quick pressure test and was quite impressed with the speed at which it reached 400 BAR/5800 PSI! It's also very quiet, in fact, it's the quietest compressor I've ever owned and I've had quite a few over the years! Here's a quick video of the pressure test so you can here it running and see how fast it reached it's max capacity:

This is a 4 stage compressor running at a fairly low RPM, yet it makes nearly 10 BAR of pressure per stroke!

After ensuring everything was operating correctly, I filled my LSC SK-19's 580cc tank from 150 BAR to 250 BAR. This fill only took about a minute and the temerature of the compressor barely rose 4 degrees!

I did add a temperature Gauge, not that it's needed with how cool this compressor runs, but I just like seeing what's happening when filling!

Here are some pictures of what's under the hood:

This is the 4 stage compression chamber with cooling fins covering the entire outer cylinder.

This is the 350X motor driving this beast and providing cooling air to the radiator.

The auto shutoff pressure gauge is really top notch! Much nicer than what comes on most lower end Chinese compressors. It has 2 set needles, I'm assuming one is a back-up in case thefirst doesn't work. I set it at 400 BAR. The second I set at my desired fill capacity. I will say I have found the gauge to be very accurate, much more so that most of the compressors I have owned.

This is the resivoir for the cooling system. The whole self-contained system hold about 1 liter of water/coolant.

Here's another angle of the radiator.

Here is the burst disk and grease pot, both these are accessible with the cover on the compressor.

The intake filts elbow was swing loose when I first opened it up, so I snugged it down so it wasn't loose. I'm not sure what the white part is attached to the head, but think it might be a temperature sensor.

Here is the main controller board.

When you remove the top of the grease pot, you can see the grease inside. The manual says to turn the knob on the top of the grease pot one full turn every 4-6 hours of operation. I need to contact GX and ask what type of greese to use, just to have some on hand if needed down the road.

The rest of the grease inside the grease pot.

This is how it looks with the cover on it, you can see the knob has arrows showing the direction to turn it when needed.

GX Claims this compressor has a 5 hour run cycle and is rated to fill up to a 6.8L air tank! Seeing that the temperature gauge barely moved when topping off the 580cc tank on the SK-19, I have no doubt that heat is not a huge problem with this compressor!

Amazon is selling these for $699.99 plus tax, but buying direct from GX Pumps, you can save over $100! They are currently on sale for $659.99, but by using the coupon code [GXPUMPS10OFF] it brings it to $593.99 shipped.

Thus far I am really quite impressed with the feature of this compressor for it's price point! It seems very solid and built to last. If interested, check out what they offer direct, they seem to alway have several different models in stock and on sale!

GX Pump PCP Air Compressor | GX CS4 Air Gun Compressors 2023

GX CS4 Portable PCP Air Compressor, 350W Powerful Motor,Max 5800Psi/40Mpa, Water and Fans Cooling, 5 Hours Continous Work, 12V Auto Stop,for PCP Air Rifle Paintball

If you have any questions, please post them below and I'll try my best to answer them.

Last edited: