You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GX2 Failure….

- Thread starter EPG

- Start date

Well???

Is this one broken exactly the same way or is it preassembled and has that open spot ?

This is a piston kit showing bad ring and the new in the bag .

Lol.

Ijdk.. don't look like used in anyway..

So far the only picture I found ..

So that white ones gone ?

Is this one broken exactly the same way or is it preassembled and has that open spot ?

This is a piston kit showing bad ring and the new in the bag .

Lol.

Ijdk.. don't look like used in anyway..

So far the only picture I found ..

So that white ones gone ?

Last edited:

Upvote 0

Have you tried to contact Bill at Targetforge.net with this issue? I am interested to learn what the seal in question should look like.

Upvote 0

Gx part that black one has that big opening I seems looking at it here b( top left)Have you tried to contact Bill at Targetforge.net with this issue? I am interested to learn what the seal in question should look like.

GX-E-CS2 GX-E-L2 Rings , Applicable to CS2 and L2

Only available in USA and Europe GX-E-CS2 GX-E-L2 Rings Applicable to CS2 and L2

Upvote 0

I wonder if that particular piece is only a bearing surface and has nothing to do with pressure. Looking at a similar picture on the Targetforge.net website shows the upper white ring, below the piston top, to have a similar opening (https://targetforge.net/shop/ols/products/complete-piston-assemblies-assembly-dwg-s-63-86-one-each). Now I am even more interested to learn how this compressor works.

Upvote 0

Well???

Is this one broken exactly the same way or is it preassembled and has that open spot ?

This is a piston kit showing bad ring and the new in the bag .

Lol.

Ijdk.. don't look like used in anyway..

View attachment 528618

So far the only picture I found ..

So that white ones gone ?

Hi Hateful,

No, the problem is that my upper black piston guide is completely missing.

I believe it disintegrated (you should’ve heard the noise) due to the likely cheapest part in the CS2 failing - the retaining ring on the

Upvote 0

That's good and stuffs available to fix it seems ..BTW, These are super freaking simple to tear down.

-Ed

Maybe send gx a tear stained email and maybe they send you the kit ? ..lol.

Upvote 0

Hopefully it’s only seals, anything more then that and parts are hard to get or more expensive then replacement.

Upvote 0

Single ring guide is common on these.

Can't see the top of the piston, or the bottom high pressure real well.

What did the cylinder head look like? Did it look like this?

Edit, see your snap ring broke... that is extremely rare unless someone has removed and reinstalled it incorrectly.

Regardless, the single piston guide on the bottom is common and not the reason for the failure. Check your cylinder wall really well for scratches.

Can't see the top of the piston, or the bottom high pressure real well.

What did the cylinder head look like? Did it look like this?

Edit, see your snap ring broke... that is extremely rare unless someone has removed and reinstalled it incorrectly.

Regardless, the single piston guide on the bottom is common and not the reason for the failure. Check your cylinder wall really well for scratches.

Last edited:

Upvote 0

Single ring guide is common on these.

Can't see the top of the piston, or the bottom high pressure real well.

What did the cylinder head look like? Did it look like this?

Edit, see your snap ring broke... that is extremely rare unless someone has removed and reinstalled it incorrectly.

Regardless, the single piston guide on the bottom is common and not the reason for the failure. Check your cylinder wall really well for scratches.

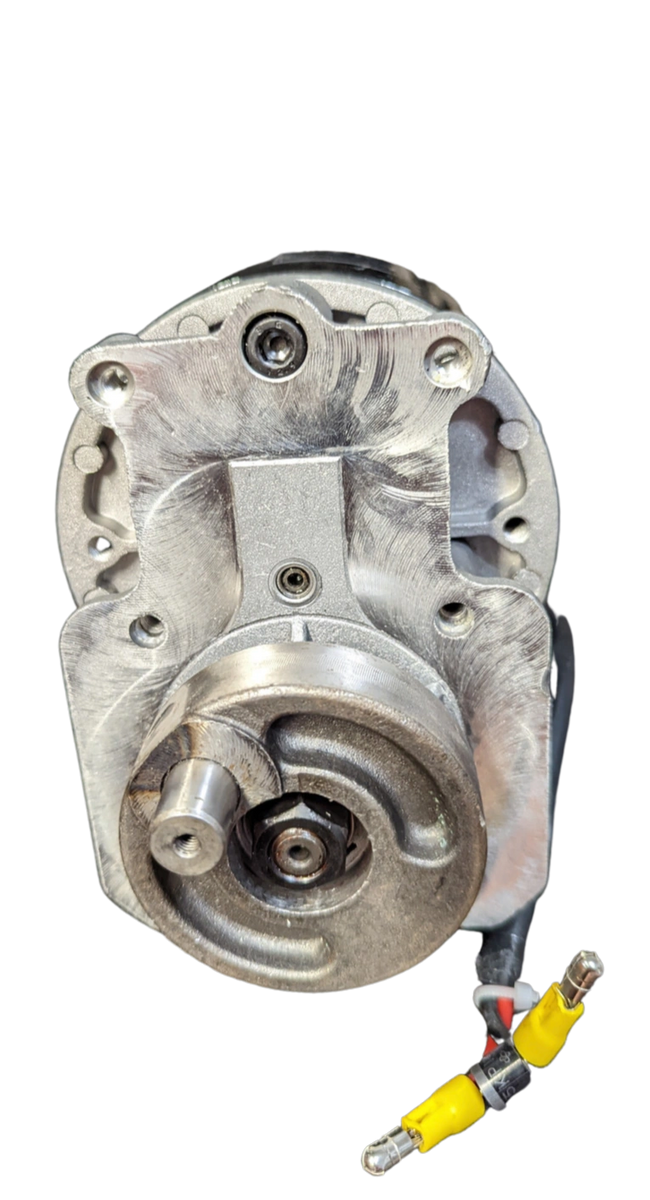

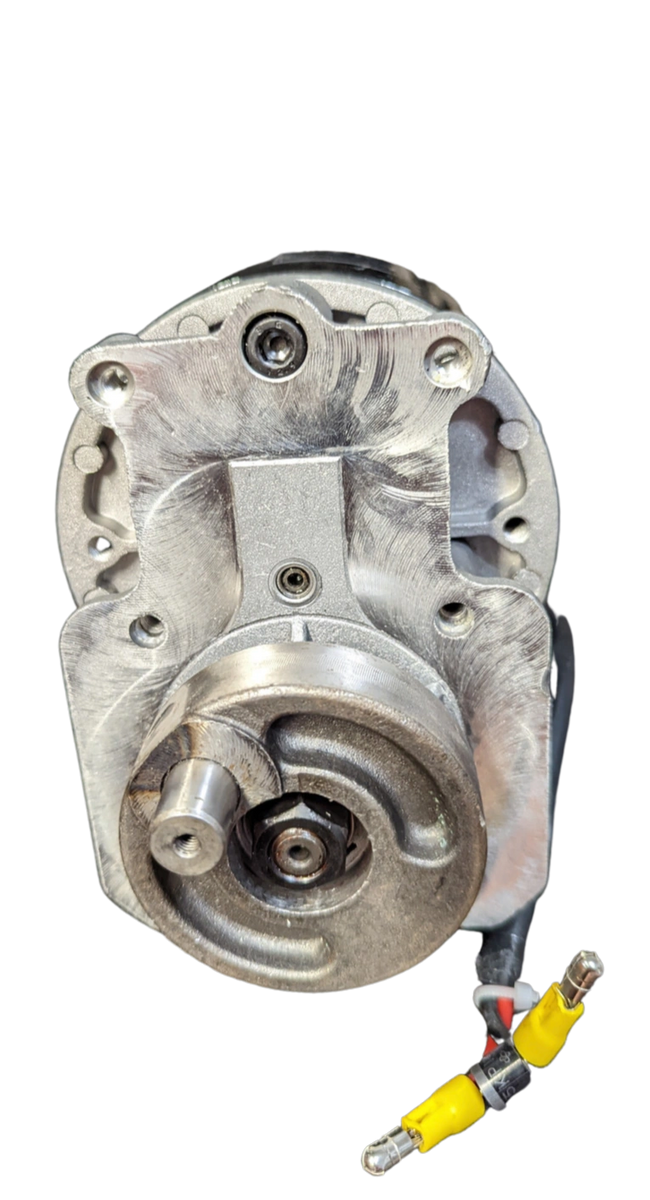

View attachment 528675

View attachment 528676

Hi 1900Colt,

Yep, you are correct, the single piston guide and broken snap ring were not the reason for failure.

I went really deep, these gears were smoked. I removed the black gunked up grease and moly greased in hopes that it might revive, but to no avail. If GX sold a replacement gear, I could revive this baby, everything else is now lubed better than new and raring to run…

I used her almost daily for 3 years, she was a good friend.

-Ed

Upvote 0

Good to see they use metal gears and a real bearing. I would say lasting 3 years of daily use is good for the price of the product. I hope to get the same out of my CS4. I never opened it up to check on the gears and lubrication, but was concerned they may have cheap out and use a large nylon gear and bushing that would wear much faster.

Which gear is worn more? I would gear the pinion gear on the motor's shaft.

Which gear is worn more? I would gear the pinion gear on the motor's shaft.

Upvote 0

Good to see they use metal gears and a real bearing. I would say lasting 3 years of daily use is good for the price of the product. I hope to get the same out of my CS4. I never opened it up to check on the gears and lubrication, but was concerned they may have cheap out and use a large nylon gear and bushing that would wear much faster.

Which gear is worn more? I would gear the pinion gear on the motor's shaft.

It is the large gear that is worn out - NOT the pinion gear on the electric motor shaft - that still looked new.

This is my 2nd GX CS2 that died due to that exact same big gear wearing out.

1900Colt informed that they have not seen this gear wear out before - except if the user is starting the compressor under load. (1900Colt performs warranty work for GX)

I never started my CS2s under load. Always started with bleed valve open. When shutting down of course I always opened the bleed valve first to depressurize the fill hose. Then I would shut off the compressor.

Perhaps I should have let the compressor run for about 30 seconds depressurized - before turning off. I’ll do that if I own another CS2.

Warranty info:

I did get a lot of use out of my CS2s - daily. First one only lasted 9 months - replaced by GX under warranty.

The second replacement CS2 lasted over 2.5 years. Incredibly, I bought the Asurion warranty from Amazon (I usually never buy extended warranties).

When the 2nd CS2 failed, I actually remembered that I bought the Asurion extended warranty and just called up my Amazon order and there was a link to file a warranty claim.

Asurion collected some basic info, I wasn’t expecting much from them, and then a day later they issued me a full refund for the CS2 - as an Amazon gift card !

Damn, I was surprised!! I’d say the extended warranty on these high pressure compressors may be worth getting.

-Ed

Last edited:

Upvote 0

GX CS2 CS3 Motor Gearbox Assembly

These motors may need slight modification for use in a CS2, I think they where connectorized at the manufacturer for the CS3 but electrically they are identical. SHipping on these from China is driving this price I am working on solutions to that in the future, but for now, this is as good as it...

targetforge.net

targetforge.net Might as well buy a new cs2. Keep old one for parts.

Upvote 0

GX CS2 CS3 Motor Gearbox Assembly

These motors may need slight modification for use in a CS2, I think they where connectorized at the manufacturer for the CS3 but electrically they are identical. SHipping on these from China is driving this price I am working on solutions to that in the future, but for now, this is as good as it...targetforge.net

Might as well buy a new cs2. Keep old one for parts.

Agree. However, the CS2 seems so well designed and built that I’ve never had a failure of any part EXCEPT for the big gear in the gearbox. So I’ve got two CS2s worth of spare parts - just sold one of those sets to a fellow AGN member.

Knowing now how easy it is to tear down into that gearbox, if I own another CS2, I will definitely do that at least once per year - and lubricate that gearbox with some high quality moly bearing grease.

I also now realize that even Bill from Target Forge is overgreasing the piston. The pistons have those delrin type guides (sometimes the piston just has a single lower guide - top guide omitted). There is no need to fill the crevices with grease as Bill advocates. All the extra grease does is potentially migrate down and clog up the high pressure end on the piston. I assume that’s why GX keeps telling everyone NOT to over grease.

Recommendation for greasing:

Here is what I’ve learned from various sources and recommend for piston lubrication - with MINIMAL disassembly:

- Take red cover off (4 screws)

- Remove black rubber plug in the center of the electric motor

- Remove top of cylinder (4 bolts with lock washers)

- Insert a 3mm allen key into rubber plug hole in motor - turning the allen key allows you to crank the piston up and down (pretty cool huh)

- Crank piston all the way down.

- Put a very small amount of the white food grade grease on your finger and LIGHTLY lube the cylinder wall. That’s it - leave NO excess grease.

- Putting in excess grease will just result in the piston “top hat” seal moving the grease up to your cylinder top (black piece with handle) - this part has a check valve on the bottom and your excess grease will potentially clog it.

So, 4 screws and 4 bolts to lubricate piston - thats it.

If you want to lubricate the connecting rod to piston interface, thats simple too:

- Unscrew the plastic plug on the front of the cylinder with a 8mm allen.

- Using the 3mm allen trick discussed above, crank the piston until the wrist pin is visible in the hole.

- Note the wrist pin has a hollow center. You can shoot your grease into this hole in the wrist pin. The wrist pin has a tiny hole where it contacts the connecting rod. The grease you shoot in will come out of that little hole - lubricating the connecting rod to piston interface - no disassembly required (i.e. no need to remove the retaining ring with snap ring pliers and pull out the wrist pin to lube, etc).

Gotta admit, once you understand it, GX has a very well thought out design for lubrication maintenance. Their problem is they can’t communicate this information - English instructions seem a barrier for them.

-Ed

Last edited:

Upvote 0

I have three CS2 compressors and I can say that the grease in the gear case does not look adequate, even though mine have all lasted around 3 years on the factory grease. I'm looking at what would be appropriate for that use, and from my research and talking to engineers, Cornhead grease looks to be a very good fit. It is designed for John Deere combine cornhead gear boxes. It is thicker when not being worked and thins when the gears are running to insure complete lubriction, and then thickens up, so as not to run, when at rest. It is a Polyurea grease, so it is one of the best technology greases out there right now. The real pain will be cleaning out the old grease??

Upvote 0

EPG , I read where you open your bleed valve before shutting it down . I've been mostly doing that as well . Do you think the compressors with auto stop are wearing out faster because of how they stop under pressure ? My cs2 is quiet when stopping against pressure but the Vevor I had with auto stop had a loud clunk when stopping against pressure , after a few months use . That's when I stopped using the auto stop and would bleed off the pressure first .

Upvote 0