Has anyone re-wrapped the internals on a DonnyFL FX Moderator to make it quieter? And if so what did you use and was there a significant reduction in loudness? Mine is a .25/.30 cal. moderator - shooting .25 cal. Diabolo pellets.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Has Anyone Re-Wrapped a DonnyFL FX Moderator to make it Quieter?

- Thread starter MikeAllen

- Start date

- Status

- Not open for further replies.

so far no .. other gun noise is where the barrier generally lies to getting my guns quieter .. most of the noise after putting a donny on is coming from the hammer, valve poppet and 'ping' reverberating in the airtube, so unless thats super quiet, making the fart end quieter wont do much ..

.. what i can tell you is just watch what you use, airguns can create a vacuum condition in the barrel upon firing that can suck possibly abrasive particles back into it if one used, say, scotchbrite pads or other abrasive type things ..

.. what i can tell you is just watch what you use, airguns can create a vacuum condition in the barrel upon firing that can suck possibly abrasive particles back into it if one used, say, scotchbrite pads or other abrasive type things ..

Last edited:

Upvote 0

Good thoughts - thanks.so far no .. other gun noise is where the barrier generally lies to getting my guns quieter .. most of the noise after putting a donny on is coming from the hammer, valve poppet and 'ping' reverberating in the airtube, so unless thats super quiet, making the fart end quieter wont do much ..

.. what i can tell you is just watch what you use, airguns can create a vacuum condition in the barrel upon firing that can suck possibly abrasive particles back into it if one used, say, scotchbrite pads or other abrasive type things ..

Upvote 0

I tried a few different things on my fl shogun,I even used some wrap a buddy gave me that he said was the same thing leshiy uses,nothing was quieter than the original.if you find something please post it

Upvote 0

Mike,

Sorry if I am stating the obvious, but to add to dizzums' considerations, at some point your target or trap impact becomes the dominant sound; and it can be quite loud.

Sorry if I am stating the obvious, but to add to dizzums' considerations, at some point your target or trap impact becomes the dominant sound; and it can be quite loud.

Upvote 0

Good point - my pellet trap is pretty quiet - I use a cardboard box filled with rubber mulch. I did test the theory of mechanicals making most of the noise and found that it didn’t qualify for my setup. I’m thinking maybe a moderator with multiple baffles might be the answer - like the DonnyFL Ryu or the Impulse Air.Mike,

Sorry if I am stating the obvious, but to add to dizzums' considerations, at some point your target or trap impact becomes the dominant sound; and it can be quite loud.

Upvote 0

DFL should try to combine conical baffles with the facility for felt wrapping; rather than either/or. DFL's felt wrapped mufflers are designed to make machining the insert easier.

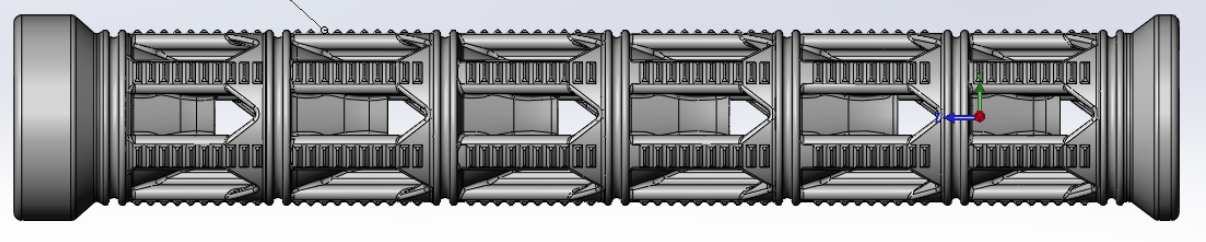

To describe what I am thinking, the 3D printable insert design shown below is intended to be felt wrapped; and live inside a tube with appropriate threaded endcaps. Now, to achieve felt wrapping the Ryu or Impulse baffle stack would need to be placed inside an outer tube too.

The baffles would also need to be skeletonized; or at least have substantial vents to the outer tube ID space. Of course, if you have a fixed length outer tube, then you need to use the right number of conical baffles to fill that, with endcaps to retain the baffles. Unless each screw-on baffle has its own screw-on sleeve to retain the felt. Or the sleeves can be retained by screwing the baffles together...

This would make the assembly more complex and expensive, but it would likely remove the metallic ring sound that emanates from the outside, and mellow the sound coming from the inside via the bore. A sound that some people report for these machined stackable baffle systems.

Another way to remove the external ringing from the Ryu and Impulse would be to wrap the baffle stack in a foam rubber sleeve. Something similar to that used for handle bars. The sound coming from the bore will still have a bit of an edge to it, compared to the felt wrapped DFL moderators, despite the potentially reduced peak dB of the conical baffle stacks.

Food for thought.

To describe what I am thinking, the 3D printable insert design shown below is intended to be felt wrapped; and live inside a tube with appropriate threaded endcaps. Now, to achieve felt wrapping the Ryu or Impulse baffle stack would need to be placed inside an outer tube too.

The baffles would also need to be skeletonized; or at least have substantial vents to the outer tube ID space. Of course, if you have a fixed length outer tube, then you need to use the right number of conical baffles to fill that, with endcaps to retain the baffles. Unless each screw-on baffle has its own screw-on sleeve to retain the felt. Or the sleeves can be retained by screwing the baffles together...

This would make the assembly more complex and expensive, but it would likely remove the metallic ring sound that emanates from the outside, and mellow the sound coming from the inside via the bore. A sound that some people report for these machined stackable baffle systems.

Another way to remove the external ringing from the Ryu and Impulse would be to wrap the baffle stack in a foam rubber sleeve. Something similar to that used for handle bars. The sound coming from the bore will still have a bit of an edge to it, compared to the felt wrapped DFL moderators, despite the potentially reduced peak dB of the conical baffle stacks.

Food for thought.

Upvote 0

I see you may have given this some thought! Thanks for your input!DFL should try to combine conical baffles with the facility for felt wrapping; rather than either/or. DFL's felt wrapped mufflers are designed to make machining the insert easier.

To describe what I am thinking, the 3D printable insert design shown below is intended to be felt wrapped; and live inside a tube with appropriate threaded endcaps. Now, to achieve felt wrapping the Ryu or Impulse baffle stack would need to be placed inside an outer tube too.

The baffles would also need to be skeletonized; or at least have substantial vents to the outer tube ID space. Of course, if you have a fixed length outer tube, then you need to use the right number of conical baffles to fill that, with endcaps to retain the baffles. Unless each screw-on baffle has its own screw-on sleeve to retain the felt. Or the sleeves can be retained by screwing the baffles together...

This would make the assembly more complex and expensive, but it would likely remove the metallic ring sound that emanates from the outside, and mellow the sound coming from the inside via the bore. A sound that some people report for these machined stackable baffle systems.

Another way to remove the external ringing from the Ryu and Impulse would be to wrap the baffle stack in a foam rubber sleeve. Something similar to that used for handle bars. The sound coming from the bore will still have a bit of an edge to it, compared to the felt wrapped DFL moderators, despite the potentially reduced peak dB of the conical baffle stacks.

Food for thought.

View attachment 399391

View attachment 399392

Upvote 0

Mike,

You seem to gravitate to name brand solutions. Have you considered a 3D printed insert that fits into your existing DFL tube?

You seem to gravitate to name brand solutions. Have you considered a 3D printed insert that fits into your existing DFL tube?

Upvote 0

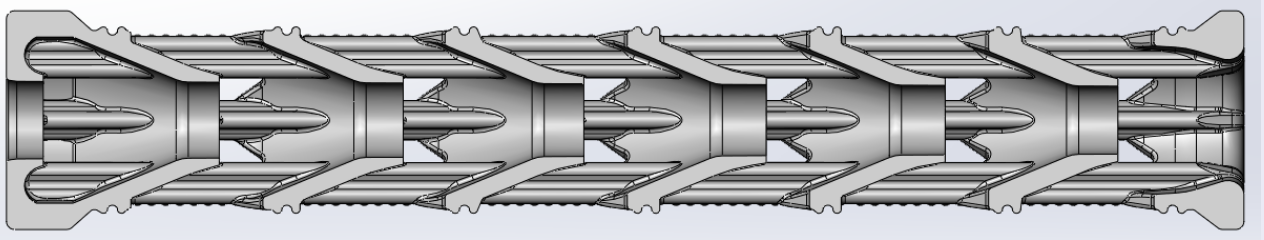

The insert in the images above is for the Altaros tube. I have done some inserts for the Shogun tube, but probably not for your DonnyFL FX moderator.

If you provide the critical dimensions with a few pics, I can generate a custom design for you. If it works as intended, then others might benefit from it too.

What power level are you shooting at? From what barrel length?

If you provide the critical dimensions with a few pics, I can generate a custom design for you. If it works as intended, then others might benefit from it too.

What power level are you shooting at? From what barrel length?

Last edited:

Upvote 0

Thanks! I’ll try to get back to you soon. I’m sure many of these are out there!The insert in the images above is for the Altaros tube. I have done some inserts for the Shogun tube, but probably not for your DonnyFL FX moderator.

If you provide the critical dimensions with a few pics, I can generate a custom design for you. If it works as intended, then others might benefit from it too.

What power level are you shooting at? From what barrel length?

Upvote 0

I made some recent changes to my shroud/moderator (.25 P15 @ 40fpe with 3d printed shroud insert + external moderator section).

I was a bit too impatient to record before and after, so I have nothing quantitative, but:

1) I found reprinting the insert in PETG (vs PLA) resulted in a marginally more pleasant sound. Less "ping".

2) I covered the shroud/moderator with 45mm dia heat shrink tubing. The tubing was almost too big, when shrunk it was tight enough, but not vacuum sealed tight. I used a large diameter so I'd have as much rubber material for damping as possible. Again the resulting sound was marginally more pleasant.

I suspect I'm well into the region of decreasing marginal improvements with my current design, so I'm happy that I got some improvement.

More thoughts:

I think felt in a silencer has a dampening effect, but it might be more significant in blocking sound transmission. Either by insulating the sound traveling directly through the insert to the can, or by providing an additional interface/boundary for sound waves to traverse. In home audio, you can go nuts buying sound dampening wall board, but it doesn't help much if you fasten it rigidly to the framing. Doing some research on sound transmission through thin panels, in one paper the more effective methods all involved a some softer outer material with a small air gap to the panel. The primary result were much less sharp reflections and therefore lower peak sound levels.

I was a bit too impatient to record before and after, so I have nothing quantitative, but:

1) I found reprinting the insert in PETG (vs PLA) resulted in a marginally more pleasant sound. Less "ping".

2) I covered the shroud/moderator with 45mm dia heat shrink tubing. The tubing was almost too big, when shrunk it was tight enough, but not vacuum sealed tight. I used a large diameter so I'd have as much rubber material for damping as possible. Again the resulting sound was marginally more pleasant.

I suspect I'm well into the region of decreasing marginal improvements with my current design, so I'm happy that I got some improvement.

More thoughts:

I think felt in a silencer has a dampening effect, but it might be more significant in blocking sound transmission. Either by insulating the sound traveling directly through the insert to the can, or by providing an additional interface/boundary for sound waves to traverse. In home audio, you can go nuts buying sound dampening wall board, but it doesn't help much if you fasten it rigidly to the framing. Doing some research on sound transmission through thin panels, in one paper the more effective methods all involved a some softer outer material with a small air gap to the panel. The primary result were much less sharp reflections and therefore lower peak sound levels.

Upvote 0

.25, 600mm barrel, just under 60fpe - what critical dimensions do you need? Earlier you said thread diameter and pitch - not sure how to accurately measure the pitch but I'll see what I can do!The insert in the images above is for the Altaros tube. I have done some inserts for the Shogun tube, but probably not for your DonnyFL FX moderator.

If you provide the critical dimensions with a few pics, I can generate a custom design for you. If it works as intended, then others might benefit from it too.

What power level are you shooting at? From what barrel length?

Upvote 0

.25, 600mm barrel, just under 60fpe - what critical dimensions do you need? Earlier you said thread diameter and pitch - not sure how to accurately measure the pitch but I'll see what I can do!

Start with the FX or DFL model name so I can find images of it taken apart. Or take yours apart and take some pictures. If it is like the Shogun then the inner machine "spool" has a thread at one end.

In the case of the Shogun, that 10 mm deep female thread is a nominal 25 mm with a 1 mm pitch. There is an endcap that threads into that. It is easier to measure the stock male threads - assuming your moderator screws together like the Shogun. If it is a 25 mm thread it will measure perhaps 24.8 on its OD. Very likely that the pitch is 1 mm; or 1.25; or 1.5 mm.

The part this fits inside the stock outer tube will have at least part of its OD a close fit with the outer tube ID. I need those diameters. I need the length of the insert that is contained in the outer tube, so a printed one can substitute the stock "spool". The part should stop on a shoulder, so threaded end to shoulder length matters. See images of a Shogun insert I designed to see what dimensions are required.

Measuring the ID of the tube would also help, as I need to leave space for the felt; while making the insert snug at the ends to ensure good alignment.

If you show pictures of your moderator taken apart, we can see if the construction is different that the Shogun, possibly requiring a different approach.

Upvote 0

I’ve had it apart before so I know I can get you the information. I also have a digital caliper so I can be pretty precise.Start with the FX or DFL model name so I can find images of it taken apart. Or take yours apart and take some pictures. If it is like the Shogun then the inner machine "spool" has a thread at one end.

In the case of the Shogun, that 10 mm deep female thread is a nominal 25 mm with a 1 mm pitch. There is an endcap that threads into that. It is easier to measure the stock male threads - assuming your moderator screws together like the Shogun. If it is a 25 mm thread it will measure perhaps 24.8 on its OD. Very likely that the pitch is 1 mm; or 1.25; or 1.5 mm.

The part this fits inside the stock outer tube will have at least part of its OD a close fit with the outer tube ID. I need those diameters. I need the length of the insert that is contained in the outer tube, so a printed one can substitute the stock "spool". The part should stop on a shoulder, so threaded end to shoulder length matters. See images of a Shogun insert I designed to see what dimensions are required.

Measuring the ID of the tube would also help, as I need to leave space for the felt; while making the insert snug at the ends to ensure good alignment.

If you show pictures of your moderator taken apart, we can see if the construction is different that the Shogun, possibly requiring a different approach.

View attachment 399637

View attachment 399638

View attachment 399639

View attachment 399644

Upvote 0

What a cool option subscriber is offering us here!:

Take the attractive and tough shell of a DFL —

throw out the low tech guts —

and fill it with customized high tech components from subscriber —

for maximum performance!

These surely are good times to be an airgunner!

Matthias

Take the attractive and tough shell of a DFL —

throw out the low tech guts —

and fill it with customized high tech components from subscriber —

for maximum performance!

These surely are good times to be an airgunner!

Matthias

Upvote 0

Make a recording of before and after for us when you install the thing.I’ve had it apart before so I know I can get you the information. I also have a digital caliper so I can be pretty precise.

Upvote 0

Definitely! I also have a dB meter app on my iPhone - I'll include the readings.Make a recording of before and after for us when you install the thing.

Upvote 0

- Status

- Not open for further replies.