You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Has Anyone Re-Wrapped a DonnyFL FX Moderator to make it Quieter?

- Thread starter MikeAllen

- Start date

- Status

- Not open for further replies.

Might try that - where'd you get it?Yes, I’ve used neoprene instead of the blue felt that came with the donnyfl. 1/16” thick.

Upvote 0

Took the DonnyFL FX moderator apart and found that the internal baffle is fixed to the front end cap and cannot be removed. I might try to find one of the stock empty tubes so we can further this project but for now I’m afraid it is stalled.Start with the FX or DFL model name so I can find images of it taken apart. Or take yours apart and take some pictures. If it is like the Shogun then the inner machine "spool" has a thread at one end.

In the case of the Shogun, that 10 mm deep female thread is a nominal 25 mm with a 1 mm pitch. There is an endcap that threads into that. It is easier to measure the stock male threads - assuming your moderator screws together like the Shogun. If it is a 25 mm thread it will measure perhaps 24.8 on its OD. Very likely that the pitch is 1 mm; or 1.25; or 1.5 mm.

The part this fits inside the stock outer tube will have at least part of its OD a close fit with the outer tube ID. I need those diameters. I need the length of the insert that is contained in the outer tube, so a printed one can substitute the stock "spool". The part should stop on a shoulder, so threaded end to shoulder length matters. See images of a Shogun insert I designed to see what dimensions are required.

Measuring the ID of the tube would also help, as I need to leave space for the felt; while making the insert snug at the ends to ensure good alignment.

If you show pictures of your moderator taken apart, we can see if the construction is different that the Shogun, possibly requiring a different approach.

View attachment 399637

View attachment 399638

View attachment 399639

View attachment 399644

Upvote 0

Your call, Mike; but replacing the integral spool/endcap it part of the deal. That is how the Shogun insert works.

That said, certainly, the empty tube variety is more versatile. The designs below may be wider than you are thinking, but are inserts for an empty DFL extender tube. While one looks like it could take a felt wrap, it was not configured for it. The other one has my interpretation of a Tesla valve.

That said, certainly, the empty tube variety is more versatile. The designs below may be wider than you are thinking, but are inserts for an empty DFL extender tube. While one looks like it could take a felt wrap, it was not configured for it. The other one has my interpretation of a Tesla valve.

Upvote 0

Ok, gotcha - understood! If we go forward with this what’s my cost?Your call, Mike; but replacing the integral spool/endcap it part of the deal. That is how the Shogun insert works.

That said, certainly, the empty tube variety is more versatile. The designs below may be wider than you are thinking, but are inserts for an empty DFL extender tube. While one looks like it could take a felt wrap, it was not configured for it. The other one has my interpretation of a Tesla valve.

View attachment 399912

View attachment 399913

View attachment 399914

View attachment 399915

Upvote 0

Cost for the design/s is zip. I show images and provide STL/s. You can have it/them printed by anyone you like, or do it yourself. If you ask me to recommend someone to print for you, I have two guys that do good work and are not greedy. You would negotiate with them in private. The amount of material and print time will be the main drivers for the cost. At this point, I don't know the outside dimensions of your moderator, so I don't want to guess at the price.

This exercise is experimental with some chance that the results may not impress you. My goal is for you to prefer the sound of the replacement insert. Evidence of that would be that you elect to keep it installed, rather than put the stock parts back in. In addition, grouping ability needs to be better, or the same as stock. Certainly not worse.

If you use a dB meter to help make that decision, you need to take steps to ensure the meter does not clip (max out the reading), because then all inserts will measure the same. Ditto for not having a loud trap/target too close to the meter. It is possible for one muffler to measure a few dB lower than another, but for you to prefer the sound quality or tone of one that measures a few dB higher. Any significant difference will be immediately obvious to your ears.

So, as long as you realize that this is not a developed product that is being offered, but an experiment, your expectations should not be disappointed. If we go back to the beginning; the point is to combine a larger number of conical air strippers with a felt wrap, to see what happens.

This exercise is experimental with some chance that the results may not impress you. My goal is for you to prefer the sound of the replacement insert. Evidence of that would be that you elect to keep it installed, rather than put the stock parts back in. In addition, grouping ability needs to be better, or the same as stock. Certainly not worse.

If you use a dB meter to help make that decision, you need to take steps to ensure the meter does not clip (max out the reading), because then all inserts will measure the same. Ditto for not having a loud trap/target too close to the meter. It is possible for one muffler to measure a few dB lower than another, but for you to prefer the sound quality or tone of one that measures a few dB higher. Any significant difference will be immediately obvious to your ears.

So, as long as you realize that this is not a developed product that is being offered, but an experiment, your expectations should not be disappointed. If we go back to the beginning; the point is to combine a larger number of conical air strippers with a felt wrap, to see what happens.

Upvote 0

All sounds great. I’ll get the dimensions over to you soon. Thanks!Cost for the design/s is zip. I show images and provide STL/s. You can have it/them printed by anyone you like, or do it yourself. If you ask me to recommend someone to print for you, I have two guys that do good work and are not greedy. You would negotiate with them in private. The amount of material and print time will be the main drivers for the cost. At this point, I don't know the outside dimensions of your moderator, so I don't want to guess at the price.

This exercise is experimental with some chance that the results may not impress you. My goal is for you to prefer the sound of the replacement insert. Evidence of that would be that you elect to keep it installed, rather than put the stock parts back in. In addition, grouping ability needs to be better, or the same as stock. Certainly not worse.

If you use a dB meter to help make that decision, you need to take steps to ensure the meter does not clip (max out the reading), because then all inserts will measure the same. Ditto for not having a loud trap/target too close to the meter. It is possible for one muffler to measure a few dB lower than another, but for you to prefer the sound quality or tone of one that measures a few dB higher. Any significant difference will be immediately obvious to your ears.

So, as long as you realize that this is not a developed product that is being offered, but an experiment, your expectations should not be disappointed. If we go back to the beginning; the point is to combine a larger number of conical air strippers with a felt wrap, to see what happens.

Upvote 0

For reference, this is Mike Allen's FX DFL moderator version:

donnyfl.net

donnyfl.net

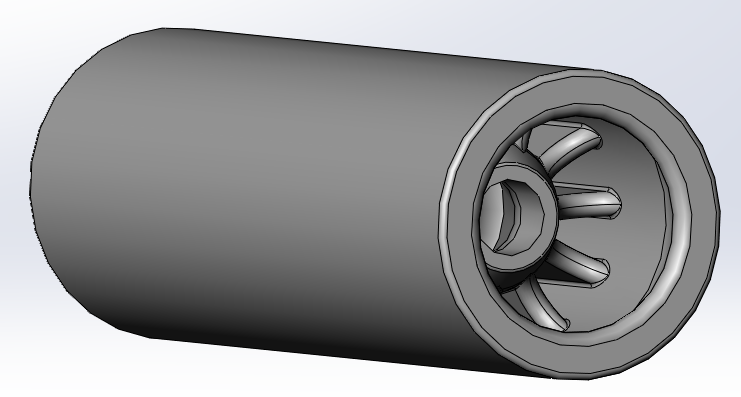

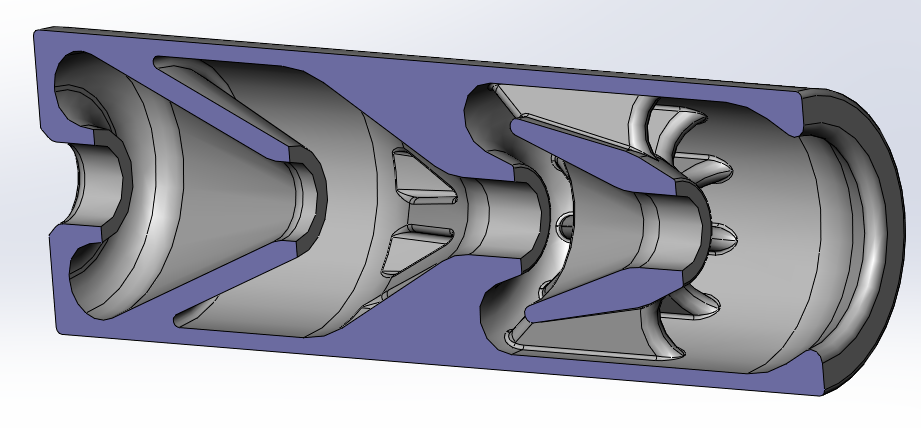

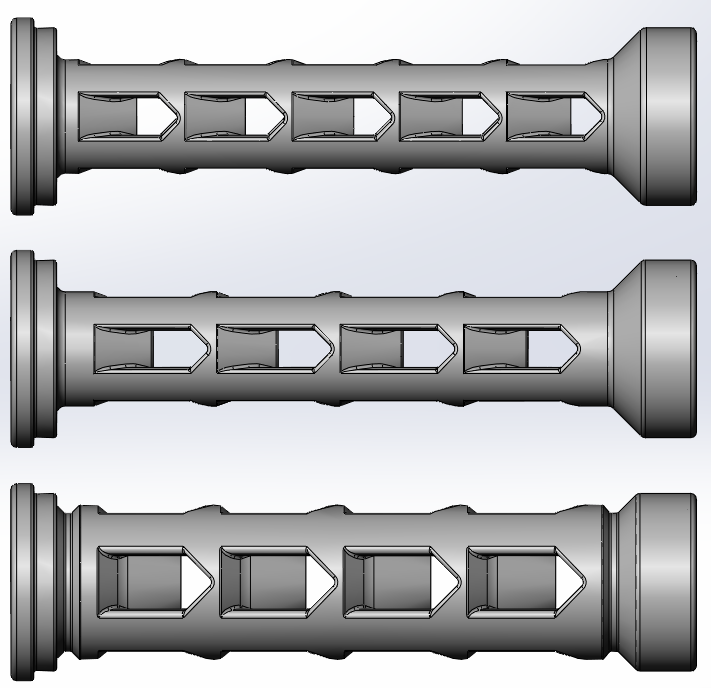

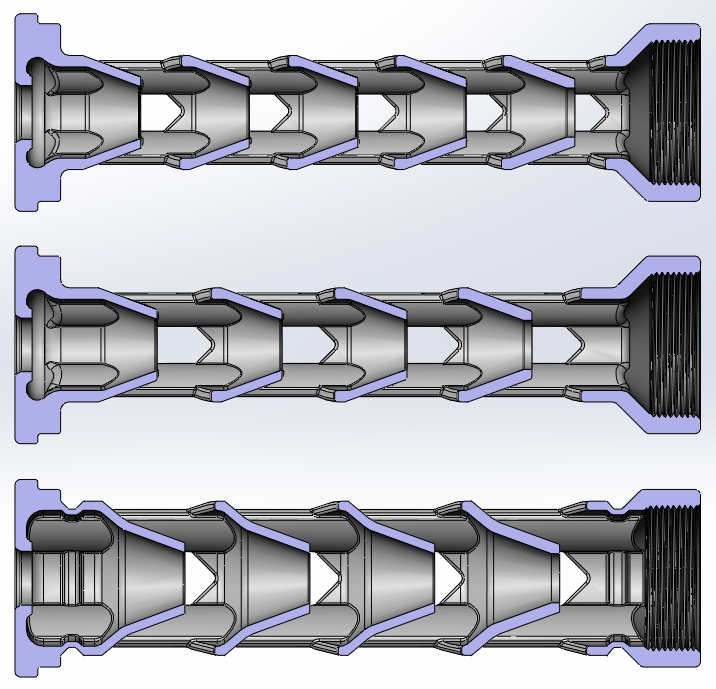

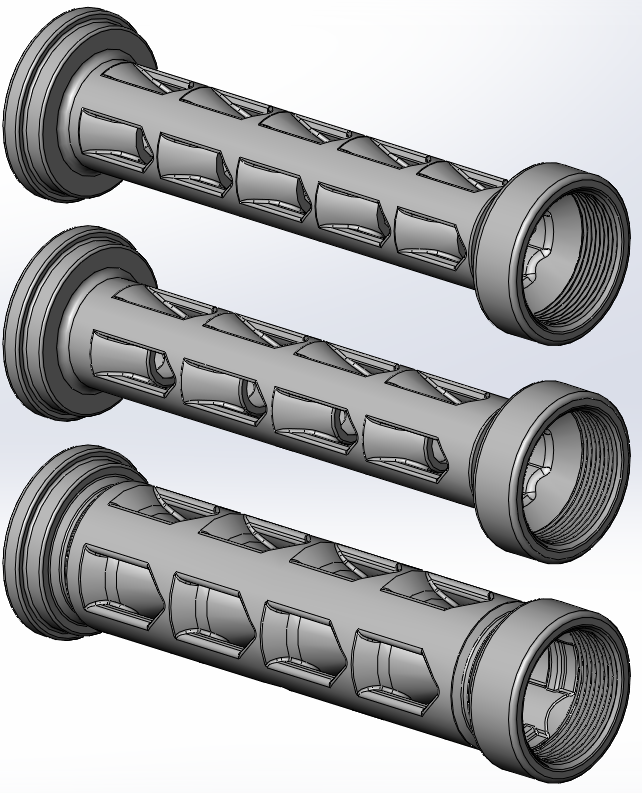

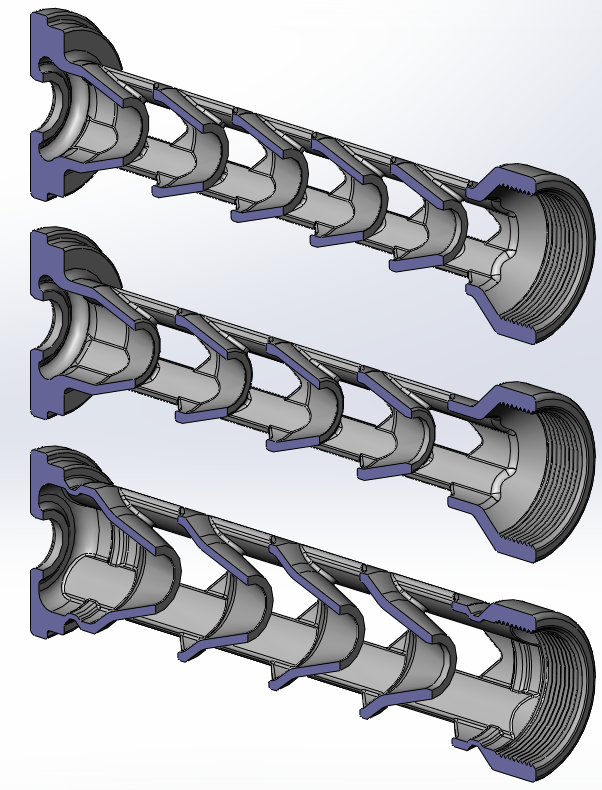

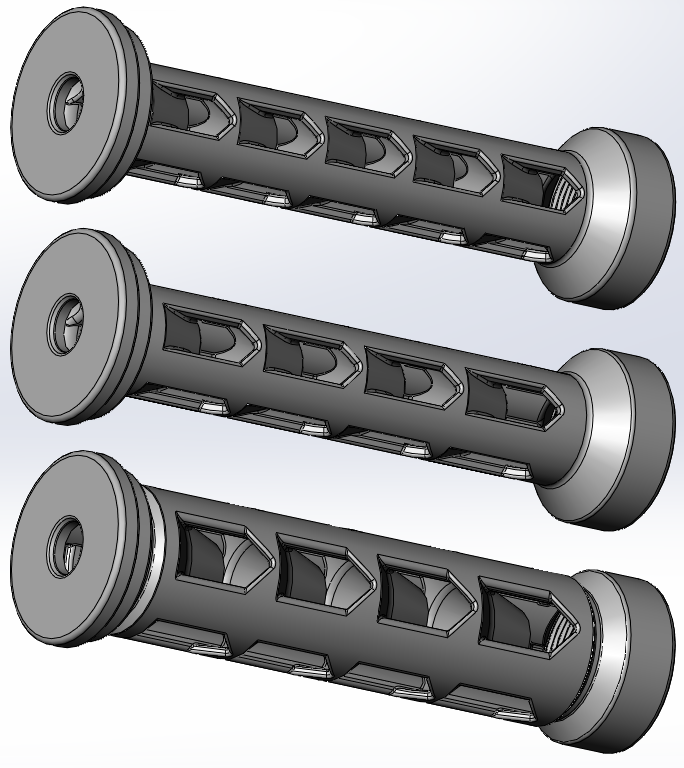

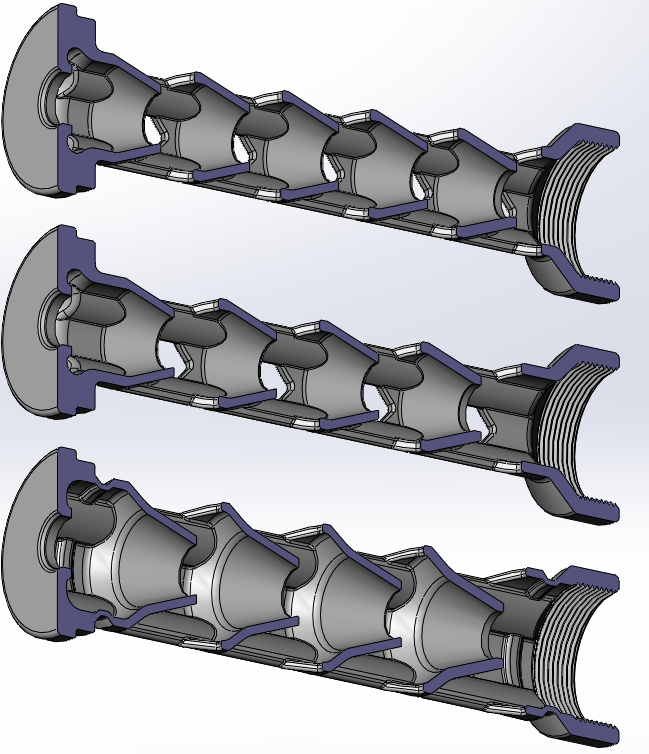

Based on Mike's question and the discussion above, I did three 3D printable insert design variants for Mike to try out. As no money changed hands, I am making the STLs available to anyone who wants to try them. They are all intended for .25 caliber - or smaller.

Version 1 and 2 are the closest to the FX DFL insert, although the felt wrapping section is a little shorter. This is to enable fitting in the cone that blends the 20 mm OD section into the 31 mm section. That cone is to enable 3D printing with supports off.

Version 3 has more open air space between baffles, with just enough open space around the periphery to take two layers of 1 mm thick felt. The idea is to span the "flats" over the open windows, and tie down the felt with wire ties in the grooves near the ends of the slotted section of the moderator. In other words, Version 3 is not trying to flow much air through the felt. Rather, the felt is intended as a very poorly sprung "trampoline", to reduce pressure wave reflection.

This, while Versions 1 and 2 have a substantial air space between the 20 mm OD section and 31 mm OD section. The idea is to use a "felt" material that is not impervious to air. Not if you stuff that entire space full of material; else you have just reduced the expansion volume of the moderator substantially. A thin layer of closed cell foam that loosely contacts the ID of the metal outer casing would be OK, because it does not take up most of that secondary air space; but acts as a poor pressure wave reflector.

The point of the exercise was to mimic the DFL design, but use more efficient conical air strippers. Version 1 has one more baffle than Version 2. Else they are the same.

See images comparing the three versions below. Version 1, 2 and 3 appear top to bottom.

The thread is sized to accept a 25 mm x 1 mm pitch male thread, straight off the printer. It is suggested that you print just the threaded portion of the part for a trial fit, using the stock endcap; before printing the whole part. You can make (the same) small adjustments to both the X and Y axis calibration in your slicer, to make the thread fit tighter or looser. Leave the Z axis at 100 %, or a pitch error will be induced.

The part and thread diameter dimensions I used are based on a history of PETG prints, produced by AGN members miksatx and TorqueMaster. You are free to print your own parts, or have anyone make prints for you. But if you asked for my recommendation, it would be the above two members.

All three STLs are in the same ZIP file - attached below.

Please note: These parts must be printed vertically, with the threads up. Else the internal cones are not self supporting during printing. Slicer support settings need to be OFF.

DonnyFL | FX Airguns Specific - 1.36 x 5 Inch Airgun Moderator

This custom-sized moderator is designed specifically for FX airguns and is available as an upgrade option for your moderator. With the same length as the Tanto but a slightly larger diameter, it offers enhanced performance comparable to the FX factory moderator. All for just $120.

donnyfl.net

donnyfl.net Based on Mike's question and the discussion above, I did three 3D printable insert design variants for Mike to try out. As no money changed hands, I am making the STLs available to anyone who wants to try them. They are all intended for .25 caliber - or smaller.

Version 1 and 2 are the closest to the FX DFL insert, although the felt wrapping section is a little shorter. This is to enable fitting in the cone that blends the 20 mm OD section into the 31 mm section. That cone is to enable 3D printing with supports off.

Version 3 has more open air space between baffles, with just enough open space around the periphery to take two layers of 1 mm thick felt. The idea is to span the "flats" over the open windows, and tie down the felt with wire ties in the grooves near the ends of the slotted section of the moderator. In other words, Version 3 is not trying to flow much air through the felt. Rather, the felt is intended as a very poorly sprung "trampoline", to reduce pressure wave reflection.

This, while Versions 1 and 2 have a substantial air space between the 20 mm OD section and 31 mm OD section. The idea is to use a "felt" material that is not impervious to air. Not if you stuff that entire space full of material; else you have just reduced the expansion volume of the moderator substantially. A thin layer of closed cell foam that loosely contacts the ID of the metal outer casing would be OK, because it does not take up most of that secondary air space; but acts as a poor pressure wave reflector.

The point of the exercise was to mimic the DFL design, but use more efficient conical air strippers. Version 1 has one more baffle than Version 2. Else they are the same.

See images comparing the three versions below. Version 1, 2 and 3 appear top to bottom.

The thread is sized to accept a 25 mm x 1 mm pitch male thread, straight off the printer. It is suggested that you print just the threaded portion of the part for a trial fit, using the stock endcap; before printing the whole part. You can make (the same) small adjustments to both the X and Y axis calibration in your slicer, to make the thread fit tighter or looser. Leave the Z axis at 100 %, or a pitch error will be induced.

The part and thread diameter dimensions I used are based on a history of PETG prints, produced by AGN members miksatx and TorqueMaster. You are free to print your own parts, or have anyone make prints for you. But if you asked for my recommendation, it would be the above two members.

All three STLs are in the same ZIP file - attached below.

Please note: These parts must be printed vertically, with the threads up. Else the internal cones are not self supporting during printing. Slicer support settings need to be OFF.

Last edited:

Upvote 0

I added a wrap of Magic Eraser (the thinnest made) to a Tanto.

It quieted things down modestly.

Enough so that I have continued to use it.

And accuracy has not been affected.

FWIW the Magic Eraser worked better in the moderator than it does as a cleaning pad

It quieted things down modestly.

Enough so that I have continued to use it.

And accuracy has not been affected.

FWIW the Magic Eraser worked better in the moderator than it does as a cleaning pad

Upvote 0

I added a wrap of Magic Eraser (the thinnest made) to a Tanto.

It quieted things down modestly.

Enough so that I have continued to use it.

And accuracy has not been affected.

FWIW the Magic Eraser worked better in the moderator than it does as a cleaning pad

Now your LDC is a Lead Dust Cleaner!

Upvote 0

I am in discussions with miksatx to print these and I’ll be doing some testing. I’ll report back!

Upvote 0

Version 2 with one of my Tanto end caps screwed down. tight fit the closer you screw to the bottom. had to use some super lube. reprinting a Version1 had to make some changes.

Upvote 0

Thanks for the update!Version 2 with one of my Tanto end caps screwed down. tight fit the closer you screw to the bottom. had to use some super lube. reprinting a Version1 had to make some changes.

View attachment 401348

Upvote 0

Version 2 with one of my Tanto end caps screwed down. tight fit the closer you screw to the bottom. had to use some super lube. reprinting a Version1 had to make some changes.

View attachment 401348

Mike, you print at the speed of light! Or at least, overnight.

Upvote 0

Thanks for the info. I’m learning that there’s a lot more to it than I originally thought!I tried wrapping cotton around the inside, it actually got louder.

Upvote 0

Someone talked about removing the felt from a donnyfl, and replacing it with cork. I have the cork, but have not tried it yet…

Upvote 0

Lemme know how it works out!Someone talked about removing the felt from a donnyfl, and replacing it with cork. I have the cork, but have not tried it yet…

Upvote 0

A Combination of a deep cone baffle + felt wraped curls have been done before, years ago by LANE .. but were he live at that moment moderators were banned.. he discontinued making them and he stay doing regulators and pcp parts.. years ago I had some make me one like the ones he used to make .and my 90fp .22 condor sound like is was damaged..you could actually only here the hammer strike..DFL should try to combine conical baffles with the facility for felt wrapping; rather than either/or. DFL's felt wrapped mufflers are designed to make machining the insert easier.

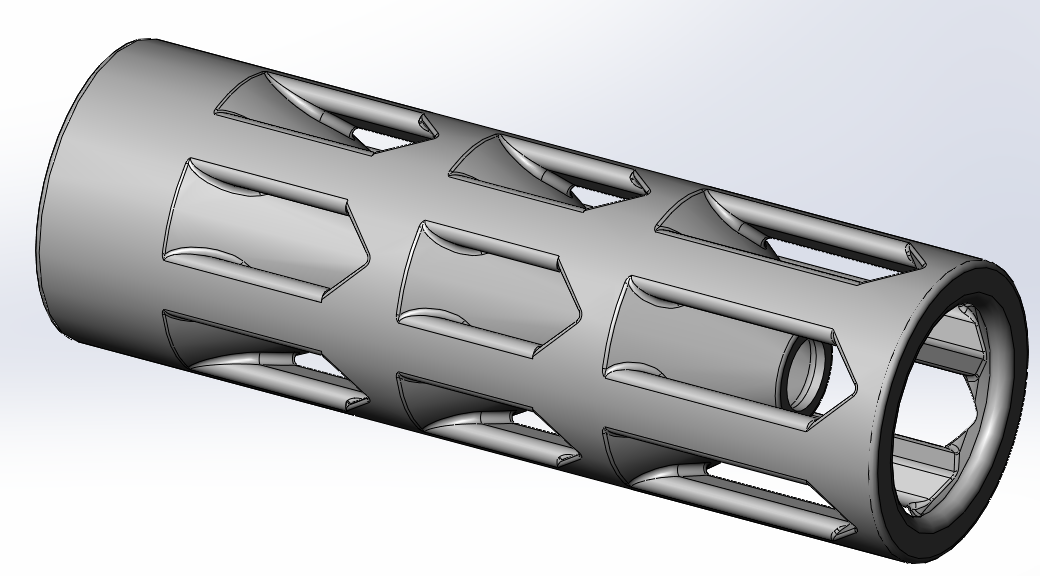

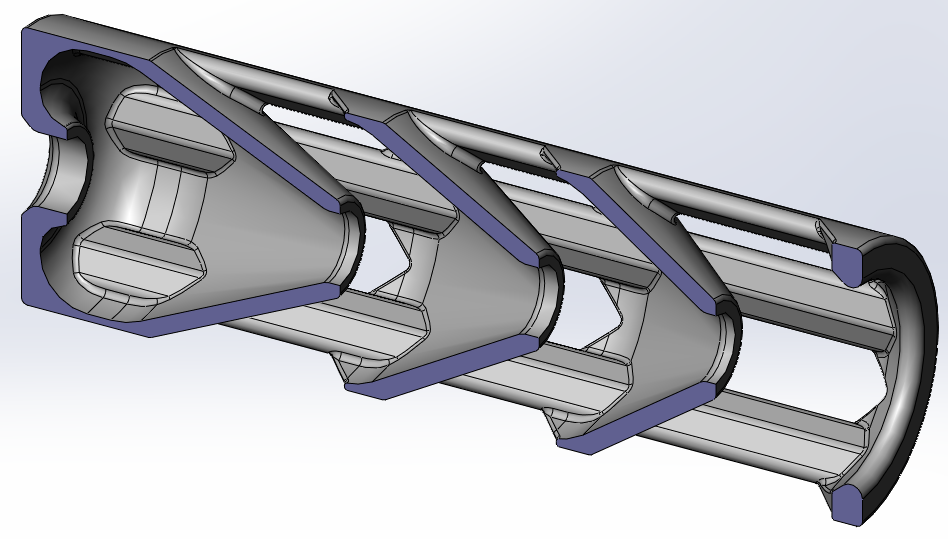

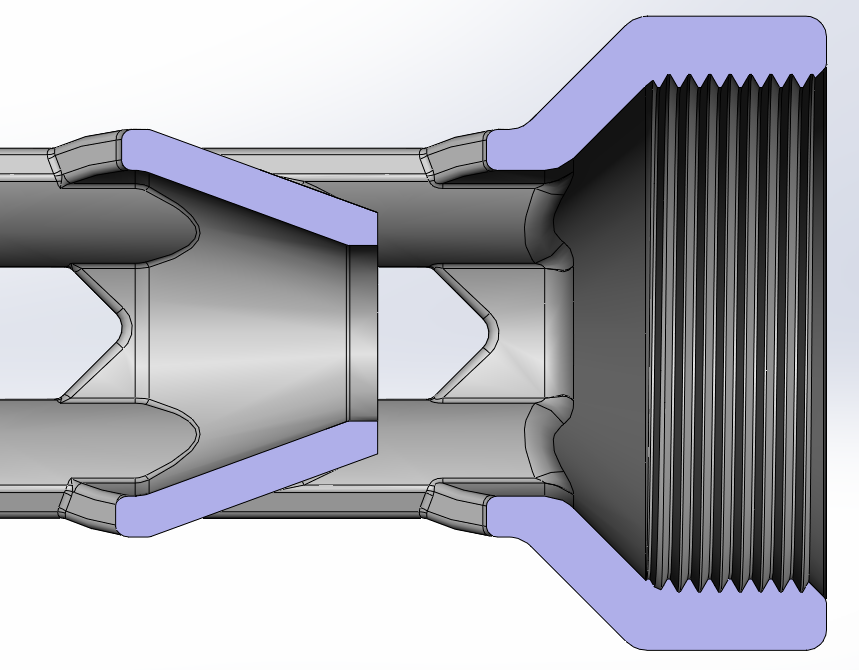

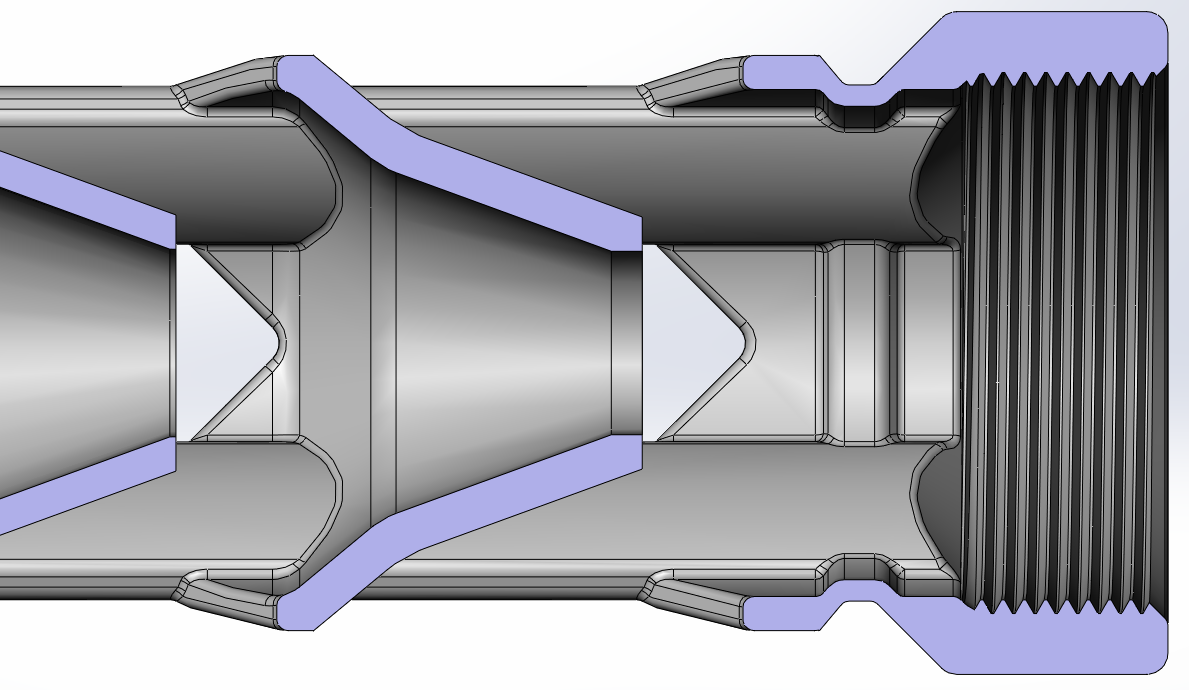

To describe what I am thinking, the 3D printable insert design shown below is intended to be felt wrapped; and live inside a tube with appropriate threaded endcaps. Now, to achieve felt wrapping the Ryu or Impulse baffle stack would need to be placed inside an outer tube too.

The baffles would also need to be skeletonized; or at least have substantial vents to the outer tube ID space. Of course, if you have a fixed length outer tube, then you need to use the right number of conical baffles to fill that, with endcaps to retain the baffles. Unless each screw-on baffle has its own screw-on sleeve to retain the felt. Or the sleeves can be retained by screwing the baffles together...

This would make the assembly more complex and expensive, but it would likely remove the metallic ring sound that emanates from the outside, and mellow the sound coming from the inside via the bore. A sound that some people report for these machined stackable baffle systems.

Another way to remove the external ringing from the Ryu and Impulse would be to wrap the baffle stack in a foam rubber sleeve. Something similar to that used for handle bars. The sound coming from the bore will still have a bit of an edge to it, compared to the felt wrapped DFL moderators, despite the potentially reduced peak dB of the conical baffle stacks.

Food for thought.

View attachment 399391

View attachment 399392

Upvote 0

- Status

- Not open for further replies.