I have a Hill Mark3 pump that I performed a rebuild on (YouTube guided) for an issue where, when pumping on the downstroke, the pump will spring back up, as if a check valve is not engaging to hold the downstroke charge. The symptom is the same after the rebuild (o-ring replacement, clean & lube). Must have missed something in the process?? Pretty much followed the guidance step by step. I am able to make the pump (downstroke) work, by bouncing the pump a few times at the lower limit and holding it there until it "catches", but even this doesn't always work. Makes pumping to 3K pretty slow though. Any thoughts? Thanks for any help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hill Mark3 Pump Rebuild Question

- Thread starter FiveString

- Start date

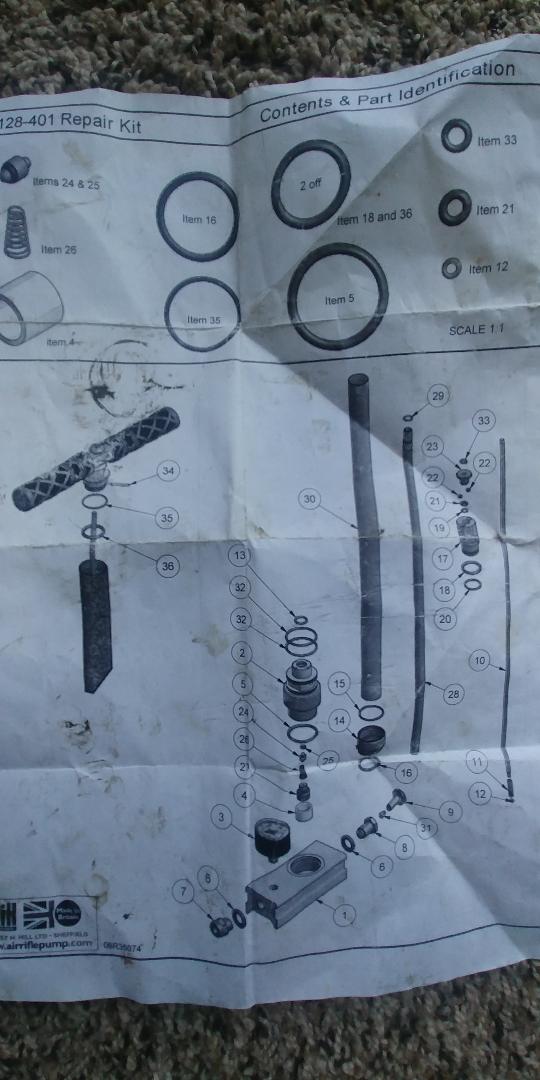

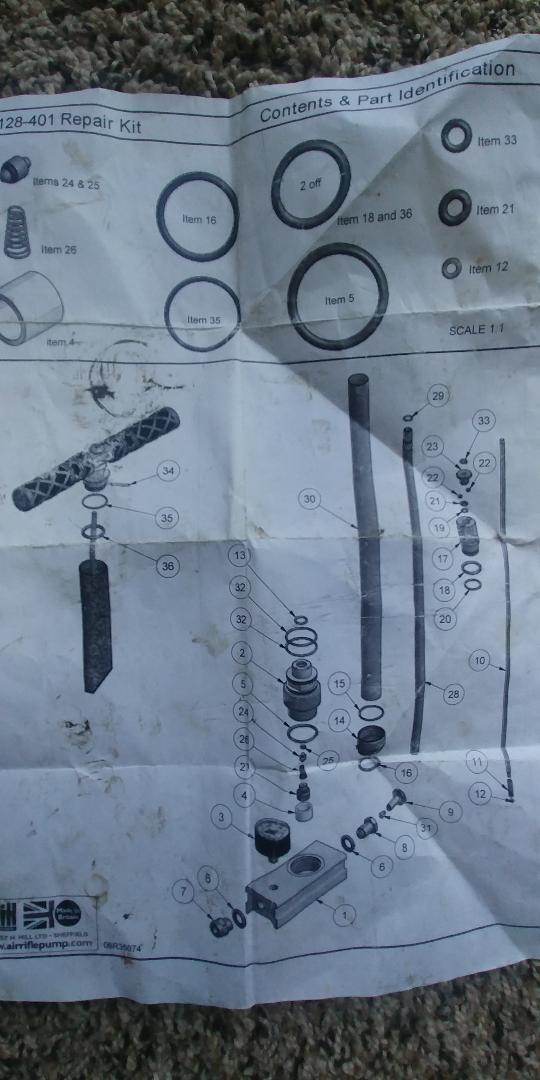

O.K. sorry for not putting this info out there, I always remind myself this is a "worldwide venue" and I have a fear of public speaking...LOL! I started shooting PCP's in 2004 with a Rapid 12, got an FX hand pump with it, in those days I worked and only shot a few hundred pellets a year, with the exception of bleeding moisture during pump up I NEVER touched the pump just used it, needless to say after about 10 years I tried to take the pump apart and found it completely shot due to no TLC. I replaced it with a Hill MK4 with drypac system, (I now have two Hill mk4's) and I started shooting more, A LOT more, now that I'm retired, more than a tin a week some weeks, I hand pump exclusively, my Hill pumps support a Rapid 12 with a 500cc bottle an Impact x with a 480cc bottle, a .25 Bobcat with a 470cc tube, a Wildcat Ml1 .25 with a 300cc tube, a Wildcat Mk1 .22 I think it has a 230cc tube, a Streamline .22 with a 190cc tube and lately a .177 Huntsman Regal not sure the tube size but I love it, easiest one to pump up, about one pump per shot! I shot almost four tins last months through this one alone. This is what I've learned about servicing Hill pumps. My first attempt at reseal ended up with the same issue as the op, long story short I couldn't find any help so I emailed Hill in England, every once in a while one finds a company who cares about their customers and their products well Hill is one of them! They had me "sorted out" in two emails! I will explain what I did or didn't do shortly, since than I have referred others to Hill with rave reviews too! When I resealed I didn't replace "good appearing" orings, WRONG, Hill knew exactly what I didn't do, #18 this oring rides on the inside of the outside housing and gets a lot of wear, I replaced that one and never looked back. I take my pumps apart and clean them every few months, orings last longer than that but cleaning in necessary, I don't use too much silicone grease just enough or it gets in the filters. I use additional filters and desiccant in a line I attach to the brass inlet filter on top of the drypac. If you have trouble with a Hill pump send them an email with as much info as you can, they care, and will help!

When I resealed I didn't replace "good appearing" orings, WRONG, Hill knew exactly what I didn't do, #18 this oring rides on the inside of the outside housing and gets a lot of wear, I replaced that one and never looked back. I take my pumps apart and clean them every few months, orings last longer than that but cleaning in necessary, I don't use too much silicone grease just enough or it gets in the filters. I use additional filters and desiccant in a line I attach to the brass inlet filter on top of the drypac. If you have trouble with a Hill pump send them an email with as much info as you can, they care, and will help!

This thread is a bit old but I figure people will always have a need for pump repair information. I too am a heavy Mk4 user. Funny, but I've never replaced #18 in that diagram. I got my pump about 4 or 5 years ago and only pumped it a few hundred cycles before it quit working (no compression / no significant air moving out the hose). I emailed Hill and they sent a reseal kit to me. Turns out that o-ring #16 in your photo (lower outer slide tube o-ring) was leaking. It happened again very quickly so I did a little measuring of o-rings before an after a self-funded repack and use. My conclusion was that the metric OEM o-ring could not handle any compression set at all before it started to leak (and all o-rings suffer from some degree of compression set as they age once installed). So I replaced the metric o-ring with a 119 size, which has slightly greater cross section, seals better, and lasts much longer (though it's still the o-ring I must replace most frequently). For replacements, I've used mil-spec 75 durometer V75 FKM and 80 durometer Aflas. They both work well. Viton in durometer 75 is probably okay too, but it has a slightly lower max. temperature rating than the two materials I've used. On the other hand, this o-ring does not run at high temps or high pressures like the little green piston o-ring (for which I've yet to find a superior non-OEM replacement, because all the candidates are similarly very high-priced but also with high minimum orders).

The high pressure piston OEM green o-ring seems to be about 90 durometer. A size 005 80 durometer Aflas is okay as a replacement for a little while but 005 90 durometer Viton leaked a bit on my pump, with the typical symptom of the handle wanting to return a little downward on the top of each upward stroke. Any 75 durometer o-ring probably won't last long at all as it will tend to extrude as pressures approach 3000 psi. The higher temp grades of 90 duro uber-expensive FFKM would be good candidates, but good luck finding only one or two of them to try in anything above 75 duro, or they will extrude and not last any longer than 75 duro Viton. The green OEM o-ring lasts a long time so I'm currently sticking to it. I haven't yet found anything cheaper that lasts.

These two o-rings along with the check valve o-ring, are the only o-rings I EVER need to replace in this pump. Any reasonable high performance o-ring choice in size 006 seems to work well for the check valve. I've used 80 duro Aflas, 75 duro FFKM (expensive for its size), and I'm now trying urethane 70 durometer cast disogrin. I buy all my o-rings online from theoringstore.

Upvote 0

When you say the green OEM o ring do you mean only the one sold by Hill and that the oringstore doesn't have anything comparable or better?

Upvote 0

When you say the green OEM o ring do you mean only the one sold by Hill and that the oringstore doesn't have anything comparable or better?

Yes--the green OEM ring sold by Hill is tough to meet or beat, because you need a shore 90A durometer o-ring to not fail fairly quickly from extrusion. Perhaps if you don't run the pump at very high pressure very often, you might get away with less than D90 . Also you'll probably want something that can take high temps or it won't last long either, unless you run the pump very cautiously at short intervals. Most FKM o-rings are rated at about 400 F (Viton). Some are a little higher. Aflas is around 450 F and FFKM (which will cost you as much as the Hill OEM replacements) will get you to temps in the high 400s. If you pick the right FFKM, you can even get into the 600s but the silicone lube will probably fail by then.. Finally, compression set vulnerability probably also plays a role in this o-ring's life. The right formulation in all these materials is important and has a significant effect on the longevity and performance. Yes--to answer your question; I've not yet found anything that I can reasonably buy (low quantities at a price under Hill's 3 for $20 price) that meats or beats the Hill geen o-ring, including at theoringstore. BTW, color is irrelevant and usually unrepresentative of an o-ring's compound so don't go by color when looking for a substitute.

You can read negative online reviews on Amazon, etc. of non-genuine Hill replacements offered at low prices. If an inexpensive replacement were easy and economical to procure, there would be some good ones out there in aftermarket "reseal kits" by now. Replacing one or two sub $7 green Hill o-rings per year really isn't bad, but I have tried unsuccessfully to find something better than the little Hill greenie while even coming close to beating the Hill price in a small order quantity.

I just saw an Ebay listing for x-ring/guad rings for the Mk3 and Mk4 piston citing positive x-ring/guad ring usage reports on Network54 airgun forums. They are probably D70 or D75 and they might last a little while, if you don't pump to 3000 psi too often. If they are D90 hardness, they might be reliable and even comparable to the OEM green o-ring, but the only x-ring / guad rings I've ever seen in small quantity are D70 or 75. Small quantities of D90 x/quad rings can be ordered on Alibaba from China, if you want to roll the Chinese dice!

Just tonight I put another 005 Viton D90 in my pump, because my green OEM is getting pretty old and it was starting to develop mild symptoms of eventual failure. I figured I'd re-try the 005 Viton D90. (I've measured them with calipers and a micrometer and also measured their hardness in an ad-hoc manner and compared them to the green OEM ring and they measure about as close as two o-rings can be!) I used a very small drop of silicone oil in assembly this time and the o-ring is sealing better than my last attempt with the Viton D90, but it was marginal tonight at first. After some pumping and, strangely, after rotating the pump handle and tube by 180 degrees, it started to function perfectly. I've tried the Viton 90 before and could not get it to completely seal. I've never had any problems after installing a new Hill greenie! I'll report back about how the 005 Viton D90 does this time. I still have one green OEM spare on hand, if the Viton fails.

I also have some Viton D75 x-rings but, fearing extrusion, I've never tried them on the piston. Maybe I'll try them sometime. I'd love to try a Viton D90 x-ring, if I can find less than 1000 of them for sale in the U.S.!

BTW, I tried a D75 119 Viton x-ring for my lower outer slide tube o-ring and it didn't work. I could not install it without damaging its edges--even after making a compression jig to install it onto the tube. A regular D75 Viton, mil-spec D75 FKM, or D80 Aflas have all worked well for me for the lower out slide tube, though Aflas compression set resistance can be rather mediocre in some formulations, I've read.

Upvote 0

I'm playing with regulator shim stacks so I'm doing a lot of pumping on my Mk4 and I have plenty of opportunities to try new piston o-rings.

The last Viton V90 didn't last very long and the x-ring ebay seller never responded to my question about durometer so I decided to just try a FKM 75 durometer X-ring from my theoringstore stash. The X-ring was a no go for me. It doesn't seal very well at all and I could even hear the bass piston scraping on the bore of the tube. There were signs of extrusion when I removed it.

Next I tried an 005 Disogen 9251 92 A durometer urethane o-ring from theoringstore. I've been reluctant to try them, because of their somewhat modest 250 F maximum temperature rating, but they are about as good as o-rings get when it comes to ruggedness in reciprocating seals, compression set resistance, and resistance to extrusion in situations where backup rings would otherwise be required. The transfer port within the piston's o-ring groove ("gland") makes the gland very wide and I've often thought about trying to custom fit the width of a Teflon backup ring on the side of the gland opposite the transfer port (which needs to seal against the o-ring rather than a backup ring during the upward stroke. The backup ring might be useful with non-OEM green o-ring choices but it must not interfere with the transfer port.

The Disogen 9251 urethane o-ring has endured a few hundred cycles now and it's still holding. I think the 250 F maximum is still practical and maybe Hill is using a urethane o-ring, disguised in green, instead of the more typical natural cloudy white color. It would also explain Hill's very conservative recommendations and cool-off periods with respect to pump heat accumulation. Even if its longevity turns out to be inferior to the OEM greenie, I'd be inclined to order some Mil. Spec. urethane duro 90s from Tim at Mac1 and try them. Mac1 is the only source I know for small quantities of mil spec urethane.

I'll keep everyone posted.

BTW, I've had excellent results after baking the Hill Dry-Pac desiccant (almost surely molecular sieve). I set my convection oven for 482 F (250 C), spread a thin layer of desiccant on a baking pan, and set the timer for 3-1/2 hours. I don't bother with a bell jar vacuum, dry gasses, or other complexities after removing it from the oven for cooling and storage. I simply pour the hot desiccant into a Bell canning jar and cap it until it cools.

Near milligram-accurate scale measurements before and after baking revealed that the desiccant holds 24% of its weight in water but, I believe it's not terribly effective in the pump after it reaches about 50% saturation. My dried desiccant lasts just as long as new Hill desiccant and I have no idea how many oven drying cycles it can endure before it loses effectiveness.

Unless you live in a very dry climate, don't shoot very much, and don't shoot a very high energy big bore PCP, I see no way that the Hill desiccant can last two or three months, as claimed. Regardless, I find that it works well when it's fresh, despite criticisms that drying should be done on the compressed air side of the pump (yup--better but extra complexity and pump-sapping dead air space). I change out my desiccant when I hear water spitting within the pump base when I quickly dump pressure to disconnect the pump.

After I've saved enough spent desiccant to fill my shallow baking pan, I crank up the convection oven. I save my Hill Dry-Pac refill bags and refill them, taping them shut with tape (metal tape preferred for improved humidity rejection). I only pay about nine or ten cents per kilowatt hour so it probably costs me somewhere around 35 cents to dry three or four refill bags full. Hill says "There is currently no method of regenerating the medium in domestic circumstances" but I read about many other methods of regenerating molecular sieve reported to be effective in online science and engineering forums and documents. Maybe my domestic circumstances are different from those in England. Maybe "most domestic circumstances" means your wife won't let you use the oven for industrial or "science fair" projects, as I call them. That's why I bought my own counter top electric convection oven that I keep in my shop for such things (also heat treating lead cast bullets, drying 3D-printer filament, etc.).

That's why I bought my own counter top electric convection oven that I keep in my shop for such things (also heat treating lead cast bullets, drying 3D-printer filament, etc.).

The last Viton V90 didn't last very long and the x-ring ebay seller never responded to my question about durometer so I decided to just try a FKM 75 durometer X-ring from my theoringstore stash. The X-ring was a no go for me. It doesn't seal very well at all and I could even hear the bass piston scraping on the bore of the tube. There were signs of extrusion when I removed it.

Next I tried an 005 Disogen 9251 92 A durometer urethane o-ring from theoringstore. I've been reluctant to try them, because of their somewhat modest 250 F maximum temperature rating, but they are about as good as o-rings get when it comes to ruggedness in reciprocating seals, compression set resistance, and resistance to extrusion in situations where backup rings would otherwise be required. The transfer port within the piston's o-ring groove ("gland") makes the gland very wide and I've often thought about trying to custom fit the width of a Teflon backup ring on the side of the gland opposite the transfer port (which needs to seal against the o-ring rather than a backup ring during the upward stroke. The backup ring might be useful with non-OEM green o-ring choices but it must not interfere with the transfer port.

The Disogen 9251 urethane o-ring has endured a few hundred cycles now and it's still holding. I think the 250 F maximum is still practical and maybe Hill is using a urethane o-ring, disguised in green, instead of the more typical natural cloudy white color. It would also explain Hill's very conservative recommendations and cool-off periods with respect to pump heat accumulation. Even if its longevity turns out to be inferior to the OEM greenie, I'd be inclined to order some Mil. Spec. urethane duro 90s from Tim at Mac1 and try them. Mac1 is the only source I know for small quantities of mil spec urethane.

I'll keep everyone posted.

BTW, I've had excellent results after baking the Hill Dry-Pac desiccant (almost surely molecular sieve). I set my convection oven for 482 F (250 C), spread a thin layer of desiccant on a baking pan, and set the timer for 3-1/2 hours. I don't bother with a bell jar vacuum, dry gasses, or other complexities after removing it from the oven for cooling and storage. I simply pour the hot desiccant into a Bell canning jar and cap it until it cools.

Near milligram-accurate scale measurements before and after baking revealed that the desiccant holds 24% of its weight in water but, I believe it's not terribly effective in the pump after it reaches about 50% saturation. My dried desiccant lasts just as long as new Hill desiccant and I have no idea how many oven drying cycles it can endure before it loses effectiveness.

Unless you live in a very dry climate, don't shoot very much, and don't shoot a very high energy big bore PCP, I see no way that the Hill desiccant can last two or three months, as claimed. Regardless, I find that it works well when it's fresh, despite criticisms that drying should be done on the compressed air side of the pump (yup--better but extra complexity and pump-sapping dead air space). I change out my desiccant when I hear water spitting within the pump base when I quickly dump pressure to disconnect the pump.

After I've saved enough spent desiccant to fill my shallow baking pan, I crank up the convection oven. I save my Hill Dry-Pac refill bags and refill them, taping them shut with tape (metal tape preferred for improved humidity rejection). I only pay about nine or ten cents per kilowatt hour so it probably costs me somewhere around 35 cents to dry three or four refill bags full. Hill says "There is currently no method of regenerating the medium in domestic circumstances" but I read about many other methods of regenerating molecular sieve reported to be effective in online science and engineering forums and documents. Maybe my domestic circumstances are different from those in England. Maybe "most domestic circumstances" means your wife won't let you use the oven for industrial or "science fair" projects, as I call them.

Upvote 0

Thanks thanks for your excellent information about the small o-ring. I guess I'll stick to the OEM Hill oring. I'm routinely using my pump to 4500 PSI. So far it's holding up and I'm still on the original o-ring. However I only do about 60 or 70 strokes and let it rest for 5 to 10 minutes before repeating again. No I'm not Superman I have it hooked up to a 1 horsepower motor with gear reduction.

Upvote 0

I'm routinely using my pump to 4500 PSI. So far it's holding up and I'm still on the original o-ring.

All the more reason to stick with the OEM greenie until something better comes up. I usually pump to only 3000 psi but I did take the Viton V90 up to 4000 with a dead head hose plug to test it. Though it was just a brief test, I think it might have started the Viton V90 downhill, because it started acting up not too much later. Even the urethane o-ring didn't feel quite right up around 4000, but it's still running, at least.

I really don't mind paying Hill's price for the greenies, because they last a long time. In fact, I've paid similarly for fancy FFKM o-rings that didn't last very long at all. Mostly I'm doing it out of interest. I no longer buy the more complete Hill kits though, because less expensive and sometimes improved options for all the other o-rings in the pump exist. As I mentioned earlier, the lower outer slide tube o-ring is far better replaced with a readily available 119 Viton V75 than the OEM o-ring. At least that's been my experience but maybe Hill has corrected that one o-ring in the MK4 and kits by now.

Is you motorized setup on YouTube? I think I saw it. Very cool! I might have to build one myself someday.

Upvote 0

I think it is on youtube but I can't find it. I used a small compressor to feed filtered and dried air at about 7 to 10 PSI into the Hill pump to speed things up. At lower pressures I can feed more than 30psi into the Hill pump! I use a Kill A watt to monitor the motors current to not exceed the maximum.

If I was to do it again I would have use 2 pump and a gear box with two output shaft 180 out of phase to get almost 2 time the output with the same size motor. The up stroke doesn't use much force.

If I was to do it again I would have use 2 pump and a gear box with two output shaft 180 out of phase to get almost 2 time the output with the same size motor. The up stroke doesn't use much force.

Upvote 0

Hi...i use a hills mk 3 pump.any idea about the correct O ring sizes..Hills never mentions them.i can service the pump easily but dont want to waste money on rebuild kits from hills..if i can manage to procure the correct o rings from elsewhere

Upvote 0

I'm not familiar with the Mk3 Hill oring sizes but if they use the little "green" high pressure oring like the Mk4, that is the on that fails mostly...I was having issues with that one failing...THE EDGES OF THAT GROOVE NEEDED DE-BURRING...since than I put any oring I can find in that groove and fit in the ID hole of the pump and it just works...has amazed me that that regular oring hold up so well...de-Burr those edges!!! HILL sent me some (3) of the green orings...seems they keep that size and material secret...I've never had any luck except buying their kit on that one. I'm a retired machinist and noticed the groove edges were "cutting" that oring...again DE-BURR THE EDGES ON THAT GROOVE!!!!!!Hi...i use a hills mk 3 pump.any idea about the correct O ring sizes..Hills never mentions them.i can service the pump easily but dont want to waste money on rebuild kits from hills..if i can manage to procure the correct o rings from elsewhere

.

Upvote 0

The green O-ring material is almost certainly hydrogenated Buna-N, a material with improved abrasion resistance compared to standard Buna-N.

This material is easy to find but not in 90 durometer, which is definitely desirable in this application for the same reason (abrasion resistance).

After some years of experimenting with different materials, my preference is Disogren cast polyurethane. Regular Buna-N can also last a long time in many pumps.

Materials I’ve tried that failed early were Viton (90 duro) and Aflas (80 duro). Silicone has poor abrasion resistance so I didn’t bother trying it.

This material is easy to find but not in 90 durometer, which is definitely desirable in this application for the same reason (abrasion resistance).

After some years of experimenting with different materials, my preference is Disogren cast polyurethane. Regular Buna-N can also last a long time in many pumps.

Materials I’ve tried that failed early were Viton (90 duro) and Aflas (80 duro). Silicone has poor abrasion resistance so I didn’t bother trying it.

Upvote 0

Where can you buy just the greenies?All the more reason to stick with the OEM greenie until something better comes up. I usually pump to only 3000 psi but I did take the Viton V90 up to 4000 with a dead head hose plug to test it. Though it was just a brief test, I think it might have started the Viton V90 downhill, because it started acting up not too much later. Even the urethane o-ring didn't feel quite right up around 4000, but it's still running, at least.

I really don't mind paying Hill's price for the greenies, because they last a long time. In fact, I've paid similarly for fancy FFKM o-rings that didn't last very long at all. Mostly I'm doing it out of interest. I no longer buy the more complete Hill kits though, because less expensive and sometimes improved options for all the other o-rings in the pump exist. As I mentioned earlier, the lower outer slide tube o-ring is far better replaced with a readily available 119 Viton V75 than the OEM o-ring. At least that's been my experience but maybe Hill has corrected that one o-ring in the MK4 and kits by now.

Is you motorized setup on YouTube? I think I saw it. Very cool! I might have to build one myself someday.

Upvote 0

Hi...any idea where can these green o rings be brought from...exclusively.whats hills calls Ring No 17 for the mk 3 pump.thanksWhere can you buy just the greenies?

Upvote 0

I've never seen a source for HNBR O-rings in 90 durometer.

However I'll repeat, cast Disogrin polyurethane has exceptional heat and abrasion resistance so that's what I use.

However I'll repeat, cast Disogrin polyurethane has exceptional heat and abrasion resistance so that's what I use.

Disogrin High Performance Cast Urethane O-Rings TODI

The strongest O-Ring material making it a popular choice in wear applications where abrasives, high pressure, and movement are present. Manufactured by Freudenberg, Disogrin® Cast Urethane 70 Durometer O-Rings are available to buy online. We make getting o-rings easy!

www.theoringstore.com

Upvote 0

that link shows 6 sizesI've never seen a source for HNBR O-rings in 90 durometer.

However I'll repeat, cast Disogrin polyurethane has exceptional heat and abrasion resistance so that's what I use.

Disogrin High Performance Cast Urethane O-Rings TODI

The strongest O-Ring material making it a popular choice in wear applications where abrasives, high pressure, and movement are present. Manufactured by Freudenberg, Disogrin® Cast Urethane 70 Durometer O-Rings are available to buy online. We make getting o-rings easy!www.theoringstore.com

of O rings...which one is correct

Upvote 0

Hill doesn't publish the sizes and in 10+ years of activity in the online airgunning community, I have found only passing mention from others that usually do not distinguish between the different pump versions over the years (i.e. MKI - MKV).

But with that said, a user on GTA stated his pump uses a -005. I fixed my pump with a -007 (a MKII, I think). Over the years, I have repaired a couple dozen pumps of various makes and models, and it was always a -005, -006, of -007 on the final stage. So for about $4 + shipping, you could get a couple of each size. Or measure the piston OD and groove diameter with calipers and extrapolate the proper size. Post back if you need help with that.

But with that said, a user on GTA stated his pump uses a -005. I fixed my pump with a -007 (a MKII, I think). Over the years, I have repaired a couple dozen pumps of various makes and models, and it was always a -005, -006, of -007 on the final stage. So for about $4 + shipping, you could get a couple of each size. Or measure the piston OD and groove diameter with calipers and extrapolate the proper size. Post back if you need help with that.

Upvote 0