This is priceless! Thanks a ton. I have a solenoid on the way from those guys, should land today. What is the OD of the solenoid that you use?You discussed an electronic hammer. I’ve done a few builds with electronic hammers and settled on a circuit configuration that I now use on all of them. I use solenoids from Circuit City (Magnetic Sensor Systems). My circuit design is shown below and a link to the solenoid that I prefer:

SOTUH02305106P - -S-20-90-22H

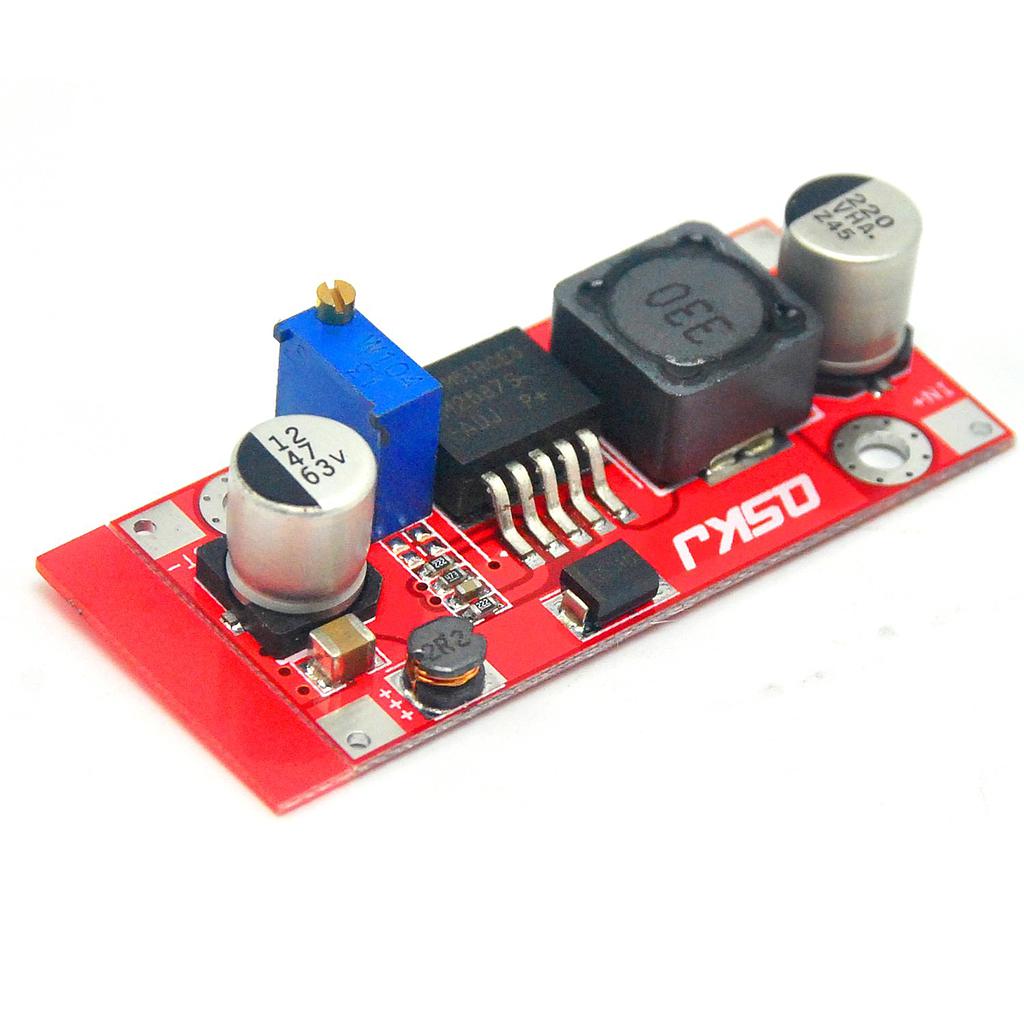

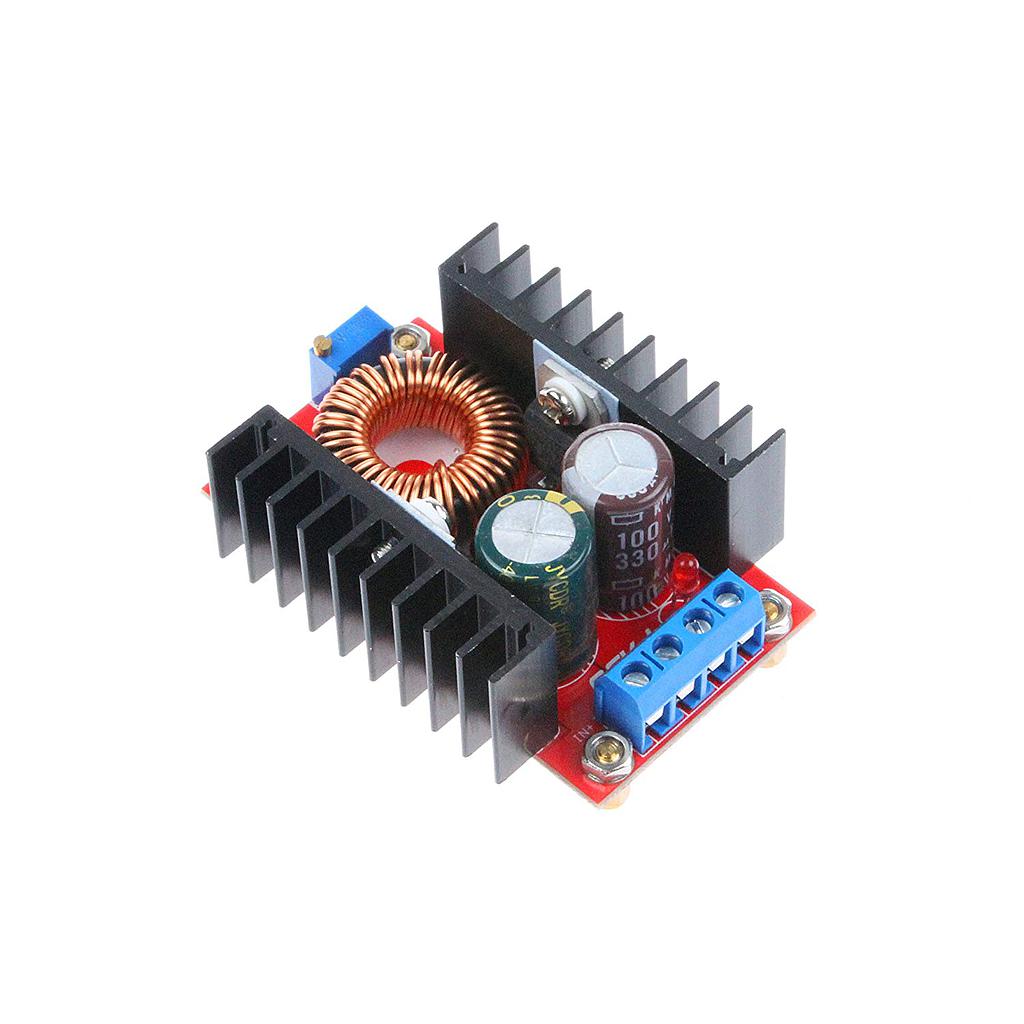

The circuit that I use is analog (no computer). The hammer strike can be controlled three ways. A mechanical stroke adjustment can be built into the design. Stroke of 1/8” to 1/2” is a good adjustment range. A higher energy hammer strike with the longer stroke might use more capacitance. Increased capacitance can also increase dwell. For on the fly hammer adjustments, the dc-dc boost converter has an output voltage adjustment pot.

By default, the circuit allows multi cycling, like a semi auto, but unless we have an auto loader mechanism, we don’t want that. So I have an electrically latched relay in the circuit so that the on/safe switch must be cycled each shot. It’s like an auto safety so that you can’t accidentally fire it multiple times.

View attachment 490354

Tubular Push Type Solenoid S-20-90-H 0.90"(23.0mm) DIAx2.00"(50.8mm) LENGTH

Tubular Push Type Solenoid, 2.00 in (72.4mm) LENGTH x 0.90 in (23.0mm) DIAMETER, MSS S-20-90-Hwww.solenoidcity.com

Upvote 0