I'll get inside of an HW97, R1, R9, AA Pro Elite, TX200 SR/standard, Walther LGU, HW50, Diana Sidelever, even the sinister P1 (preload city!), but this little pistol was "above my paygrade".

A thorough mental exercise akin to playing chess in 3D, plus it channeled my inner watchmaker self: some serious manual dexterity required, especially with part no. CS558 (x2!).

The game plan was to:

*square off the spring ends, followed by polish

*degrease and relube with the good stuff

*replace OEM HW 25mm parachute seal with an Aussie 25mm concave seal

*reverse position of the long rear guide, use as a long tophat/piston weight

*fabricate a sleeve for the piston from steel shim stock

*polish flat "bearing surface" of the long guide

*introduce zero additional preload

My thoughts were:

The Aussie seal sits almost 1mm lower than the OEM parachute seal, and has less lost volume (absence of parachute groove). The extra weight of the long guide now inside the piston will allow for more mass and a bit longer dwell time at the end of the compression stroke. Based on these mods alone (completely reversible), I expected a gain of around 30 fps. As received, in factory stock condition after break in: RWS 7gn Basics: 367 fps avg, H&N Excite Plinking Wadcutters 7.48 gn: 425 fps.

Reversing the guide position would essentially mimic the P1 set up, where the long guide is inside the piston. Only one way to find out if it will work.

Some pics of the pistol stripped down:

Yes that's the head of a JSB 7.9 Express nestled in the transfer port. It's a whopper at just over 4mm. Hmmm....

Notice the bent spring- the bend was inside the piston; the spring end was closed at an angle and not square so that didn't help. After taking care of the spring ends (polish, heated and closed/quenched/tempered, then mirror polished) the now polished long guide was slipped into the bent end which straightened it out pretty good. The fit of the guide was very nice: not loosey goosey but a push interference fit. Sleeve in place inside piston, everything lubed and assembled.

The 2 springs, CS558 (I'll never forget those) are extensions springs with hooks on both ends and articulate the trigger sear to the pistol frame. Connecting this spring to the 2 surfaces was the most tedious. It could be worse: FWB 65 or RWS 6G GISS

.

.

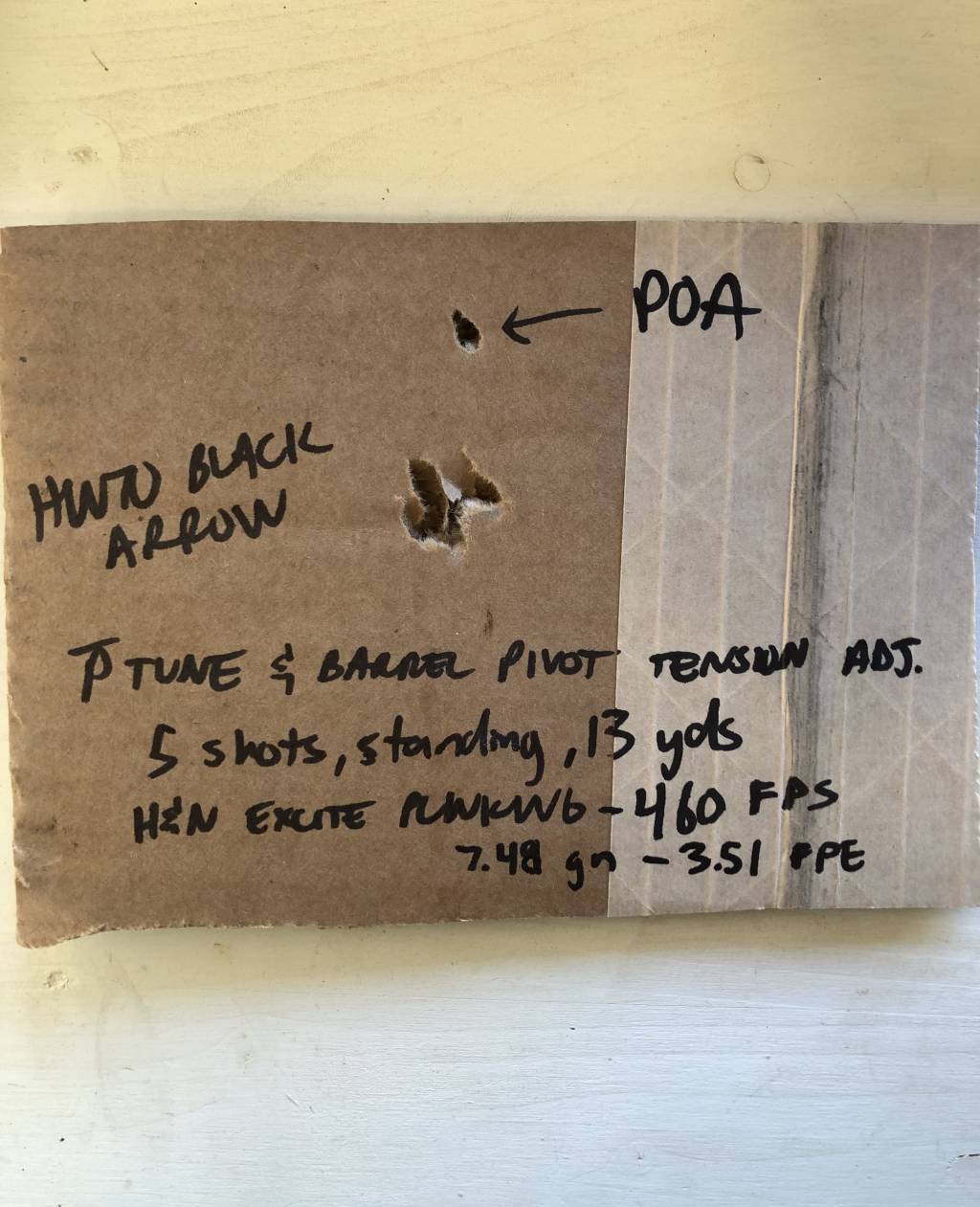

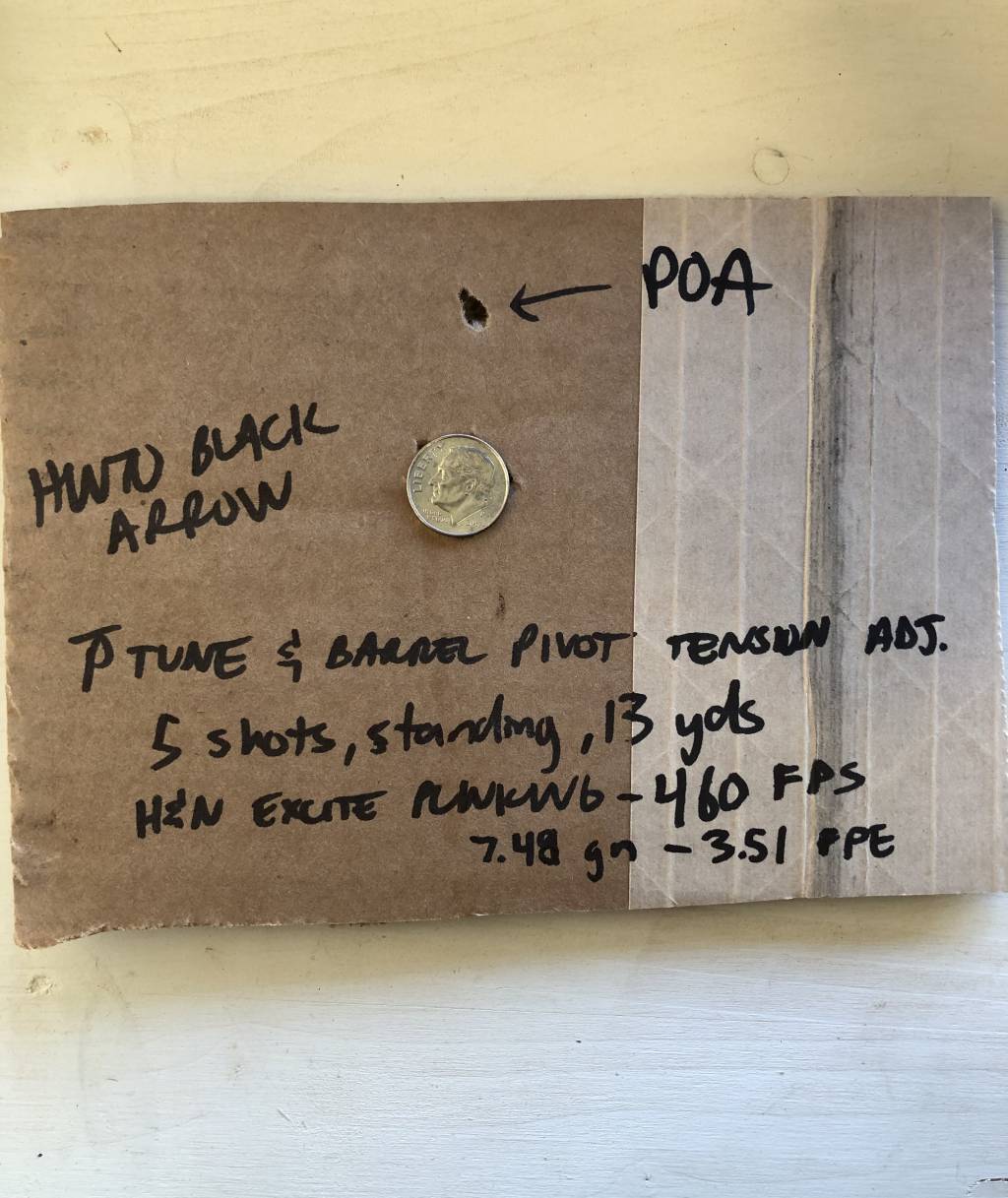

Barrel pivot tension adjusted, relubed.

Galling on undercarriage frame from the double jointed cocking lever: addressed with Dow Corning M77. I wanted to use a piece of an ARH cocking lever insert for an HW50, but it is too narrow for that, so a better solution awaits for a future project.

The results were impressive: zero dieseling/smoking from the get go and the buzz was now gone. Cocked smooth, shot smooth. The performance gains were pretty sweet as well: RWS 7gn Basics now doing 410 fps avg (43 fps higher than before) and H&N Excites 7.48gn now doing 460 fps avg (35 fps higher than before). Sweet

After some plinking and scope adjustment (POI was about 1" higher than before) a 5 shot group standing from 13 yds using H&N Excite pellets. 2 handed grip, mild breezes:

It's each little challenge that serves as a breakthrough moment. Working on this pistol was very intense and challenging but I'm glad I did it. I think if I were to sleeve the transfer port to 3-3.2mm I may be able to get close to 500 fps with the existing bore and stroke, but that's for another time.

Thanks for letting me share,

JohnnyPiston

A thorough mental exercise akin to playing chess in 3D, plus it channeled my inner watchmaker self: some serious manual dexterity required, especially with part no. CS558 (x2!).

The game plan was to:

*square off the spring ends, followed by polish

*degrease and relube with the good stuff

*replace OEM HW 25mm parachute seal with an Aussie 25mm concave seal

*reverse position of the long rear guide, use as a long tophat/piston weight

*fabricate a sleeve for the piston from steel shim stock

*polish flat "bearing surface" of the long guide

*introduce zero additional preload

My thoughts were:

The Aussie seal sits almost 1mm lower than the OEM parachute seal, and has less lost volume (absence of parachute groove). The extra weight of the long guide now inside the piston will allow for more mass and a bit longer dwell time at the end of the compression stroke. Based on these mods alone (completely reversible), I expected a gain of around 30 fps. As received, in factory stock condition after break in: RWS 7gn Basics: 367 fps avg, H&N Excite Plinking Wadcutters 7.48 gn: 425 fps.

Reversing the guide position would essentially mimic the P1 set up, where the long guide is inside the piston. Only one way to find out if it will work.

Some pics of the pistol stripped down:

Yes that's the head of a JSB 7.9 Express nestled in the transfer port. It's a whopper at just over 4mm. Hmmm....

Notice the bent spring- the bend was inside the piston; the spring end was closed at an angle and not square so that didn't help. After taking care of the spring ends (polish, heated and closed/quenched/tempered, then mirror polished) the now polished long guide was slipped into the bent end which straightened it out pretty good. The fit of the guide was very nice: not loosey goosey but a push interference fit. Sleeve in place inside piston, everything lubed and assembled.

The 2 springs, CS558 (I'll never forget those) are extensions springs with hooks on both ends and articulate the trigger sear to the pistol frame. Connecting this spring to the 2 surfaces was the most tedious. It could be worse: FWB 65 or RWS 6G GISS

Barrel pivot tension adjusted, relubed.

Galling on undercarriage frame from the double jointed cocking lever: addressed with Dow Corning M77. I wanted to use a piece of an ARH cocking lever insert for an HW50, but it is too narrow for that, so a better solution awaits for a future project.

The results were impressive: zero dieseling/smoking from the get go and the buzz was now gone. Cocked smooth, shot smooth. The performance gains were pretty sweet as well: RWS 7gn Basics now doing 410 fps avg (43 fps higher than before) and H&N Excites 7.48gn now doing 460 fps avg (35 fps higher than before). Sweet

After some plinking and scope adjustment (POI was about 1" higher than before) a 5 shot group standing from 13 yds using H&N Excite pellets. 2 handed grip, mild breezes:

It's each little challenge that serves as a breakthrough moment. Working on this pistol was very intense and challenging but I'm glad I did it. I think if I were to sleeve the transfer port to 3-3.2mm I may be able to get close to 500 fps with the existing bore and stroke, but that's for another time.

Thanks for letting me share,

JohnnyPiston