I saw this concept posted on the forums and wanted to give it a try. I have one of the cheapie pcp hand pumps that are on ebay, amazon, aliexpress. One of these:

I removed the handle at the top of the pump, drilled and tapped the air intake port to 1/4 NPT and installed a check valve:

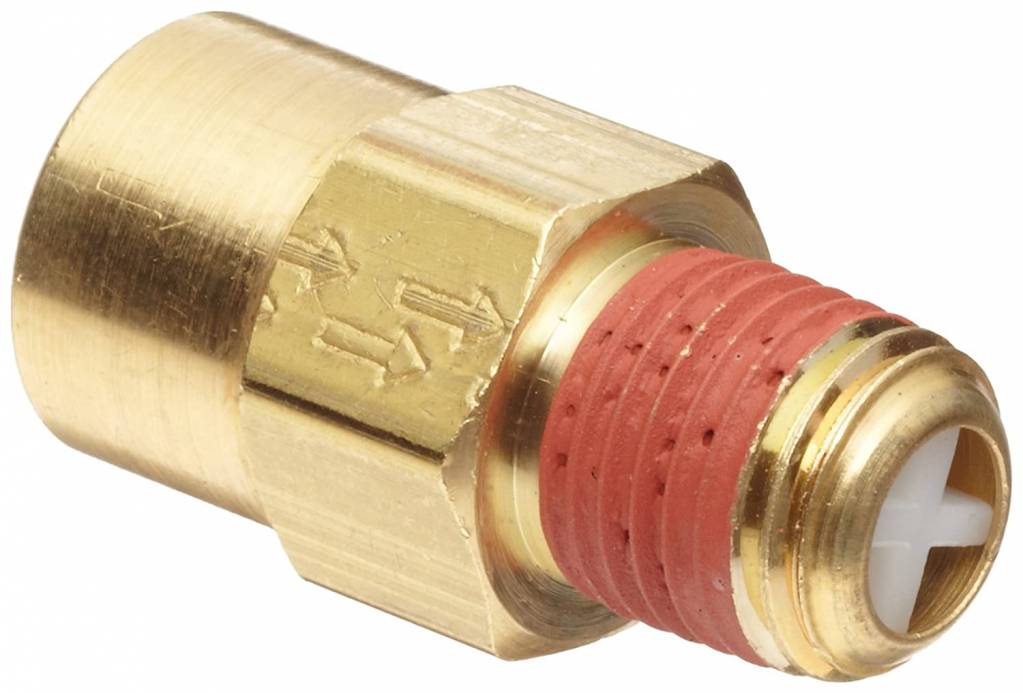

The check valve has female NPT threads, so I installed an adapter so that I could use the quick disconnect on my air compressors' hose. The diameter of the check valve was larger than expected, so I had some ...difficulties... installing a handle. 1st attempt at a handle was just to squash the original handle in a vise and use a step drill bit to get the hole to the right size:

It doesn't take a genius to figure out that this handle solution immediately bent when I got up to ~4000 psi. I found some really thick square tubing that came from another project and made a new handle:

Now I have a functioning, boosted hand pump. I have the air hose connected to the garage air compressor, regulated. When the output of the hand pump is below 3000 PSI, I can feed about 25psi of boost into the pump. Once we get to about 4000psi I have to back off the boost to around 10 psi. It really helps when filling my Cricket II Tac. Reduces the amount of time it takes to complete the task significantly. My only complaint about this setup is that I'm overheating my pump, the pump base was getting to about 160 degrees F. I filled my Cricket to 280 bar, and once the air had cooled down I was looking at about 265 bar in the tank of the gun.

For the next fill, I'm going to run the pump boosted until I hit maybe 3500psi, and then switch back to naturally aspirated so that I don't overheat the air so much. And for those wondering, the air compressor in the garage has a water separator on it, as well as an oil separator. I also am running the output of the hand pump through one of the medium sized filter thingies filled with cotton and desiccant.

I removed the handle at the top of the pump, drilled and tapped the air intake port to 1/4 NPT and installed a check valve:

The check valve has female NPT threads, so I installed an adapter so that I could use the quick disconnect on my air compressors' hose. The diameter of the check valve was larger than expected, so I had some ...difficulties... installing a handle. 1st attempt at a handle was just to squash the original handle in a vise and use a step drill bit to get the hole to the right size:

It doesn't take a genius to figure out that this handle solution immediately bent when I got up to ~4000 psi. I found some really thick square tubing that came from another project and made a new handle:

Now I have a functioning, boosted hand pump. I have the air hose connected to the garage air compressor, regulated. When the output of the hand pump is below 3000 PSI, I can feed about 25psi of boost into the pump. Once we get to about 4000psi I have to back off the boost to around 10 psi. It really helps when filling my Cricket II Tac. Reduces the amount of time it takes to complete the task significantly. My only complaint about this setup is that I'm overheating my pump, the pump base was getting to about 160 degrees F. I filled my Cricket to 280 bar, and once the air had cooled down I was looking at about 265 bar in the tank of the gun.

For the next fill, I'm going to run the pump boosted until I hit maybe 3500psi, and then switch back to naturally aspirated so that I don't overheat the air so much. And for those wondering, the air compressor in the garage has a water separator on it, as well as an oil separator. I also am running the output of the hand pump through one of the medium sized filter thingies filled with cotton and desiccant.